Method for improving micro algae growth rate and cell fat content employing high-salinity domestication

A technology of growth rate and oil content, applied in the directions of microorganism-based methods, methods of using microorganisms, biochemical equipment and methods, etc. The ability of cells to enrich oil, the effect of oil content increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

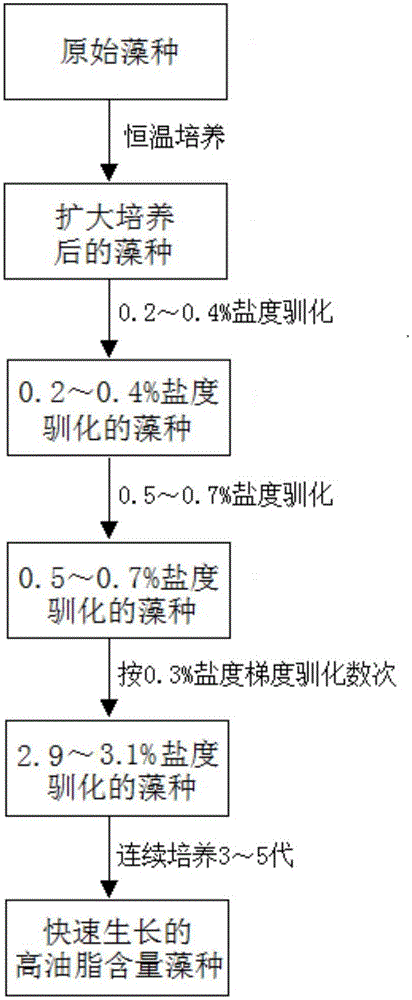

Method used

Image

Examples

Embodiment 1

[0028] (1) According to the inoculum size, inoculate the Nitzschia liquid into a 1L Erlenmeyer flask (800mL culture medium), at a constant temperature of 20°C, with a light intensity of 3500lux, and under the conditions of 12h of light and 12h of darkness in turn every day, air is passed into it to amplify the culture 10 days.

[0029] (2) Get the algal species after the expanded culture and inoculate it into a 400mL cylindrical bottle with a capacity of 5% inoculum, the medium in the cylindrical bottle is 250mL, the initial salinity is 0%, feed the air of 70mL / min, at temperature 25°C, light intensity 8000lux, light-to-dark ratio 12h:12h, and initial pH value of 9. After culturing for 8 days, transfer it to a culture medium with a salinity of 0.2% at 5-10% for 8 days. sky.

[0030] The medium consists of: 0.15g NaHCO 3 , 0.02g KH 2 PO 4 , 0.027g VB 1 , 1.5×10 -6 f 12 , 0.2g Na 2 SiO 3 9H 2 O, 1.0g NaNO 3 , 0.0005g Biotin, 1mL trace elements and 980mL artificial sea...

Embodiment 2

[0034] (1) Inoculate the Chlorella liquid into a 1L Erlenmeyer flask (800mL culture medium) according to the inoculum size of 8%, and pass air into it to amplify under the conditions of constant temperature 23°C, light intensity 3750lux, and 12h of light and 12h of darkness every day. Cultured for 12 days.

[0035] (2) Get the algal species after the enlarged culture and inoculate it into a capacity of 400mL cylindrical bottle with 8% inoculum, the medium in the cylindrical bottle is 300mL, the initial salinity is 0%, feed the air of 80mL / min, at temperature After culturing for 10 days under the conditions of 25°C, light intensity 8000lux, light-dark ratio 12h:12h, and initial pH value of 8, it was transferred to a medium with a salinity of 0.3% for 10 days at an inoculum size of 8%.

[0036] The medium consists of: 0.15g NaHCO 3 , 0.02g KH 2 PO 4 , 0.027g VB 1 , 1.5×10 -6 f 12 , 0.2g Na 2 SiO 3 9H 2 O, 1.0g NaNO 3 , 0.0005g Biotin, 1mL trace elements and 980mL artif...

Embodiment 3

[0040] (1) Inoculate the Nannochloropsis liquid into a 1L Erlenmeyer flask (800mL culture medium) according to the inoculum size of 10%, and pass air under the conditions of a constant temperature of 25°C, a light intensity of 4000 lux, and 12 hours of light and 12 hours of darkness every day. Cultured for 15 days.

[0041] (2) Get the algal species after the expanded culture and inoculate it into a 400mL cylindrical bottle with a capacity of 10% inoculum, the medium in the cylindrical bottle is 350mL, the initial salinity is 0%, feed the air of 90mL / min, at temperature After 12 days of culture at 29°C, light intensity of 9000lux, light-to-dark ratio of 12h:12h, and initial pH value of 10, it was transferred to a medium with a salinity of 0.4% for 12 days at a 10% inoculum size.

[0042] The medium consists of: 0.15g NaHCO 3 , 0.02g KH 2 PO 4 , 0.027g VB 1 , 1.5×10 -6 f 12 , 0.2g Na 2 SiO 3 9H 2 O, 1.0g NaNO 3, 0.0005g Biotin, 1mL trace elements and 980mL artificial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com