A reagent and application and equipment for detecting whether an oil layer enters a high-temperature oxidation stage

A technology of high-temperature oxidation and reagents, which is applied in wellbore/well parts, earthwork drilling and production, etc., can solve the problems of increased difficulty in secondary ignition, non-reusable use, and increased difficulty in ignition, so as to facilitate on-site analysis, high temperature The effect of short oxidation combustion cycle and increased difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] 15 Preparation of N-labeled ammonium perchlorate:

[0075] Using HClO as the starting material, high-purity HClO is obtained through two-step electrolysis 4 , and then tagged with 15 N high-purity ammonia (commercially available, product model NLM-107-1-BS) was reacted to obtain high-purity labeled ammonium perchlorate after centrifugation and drying. Specifically:

[0076] commercially available 15 NH 3 ·H 2 O, concentration 25%-28%, commercially available HClO 4 , Concentration 70%-72%.

[0077] The first step: according to 15 NH 3 ·H 2 O and HClO 4 The molar concentration ratio (without water) is 1:1 and mixed in a container.

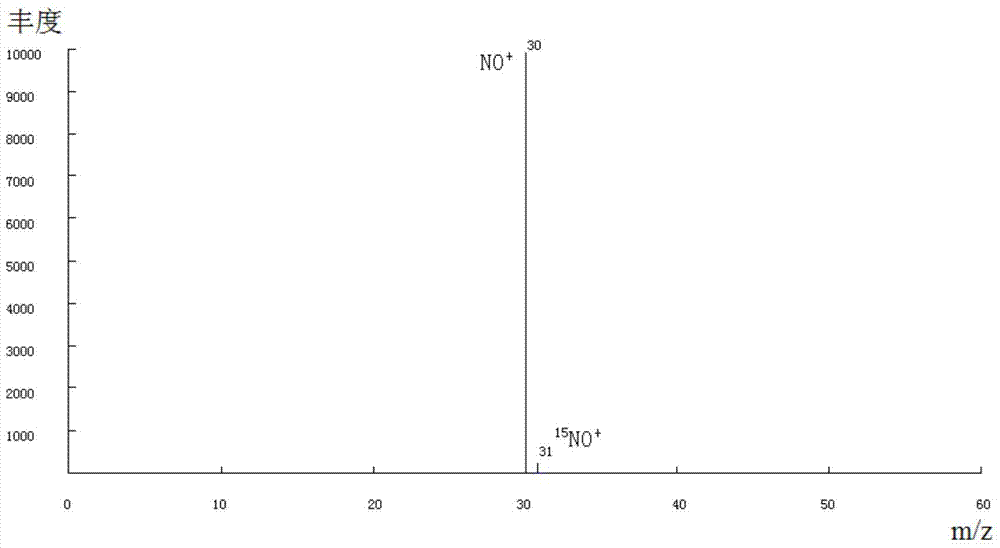

[0078] Step 2: Evaporate water in the evaporating pan under normal pressure to form 15 NH 4 ClO 4 solid, obtained 15 NH 4 ClO 4 The solid can be directly crushed in the next step without special treatment. Prepared 15 The mass spectrum of N-labeled ammonium perchlorate is as follows figure 1 shown.

[0079] The third ste...

Embodiment 2

[0096] This embodiment prepares ammonium perchlorate granule according to embodiment 1, and adds Gd 2 o 3 , the Gd 2 o 3 Consumption is 5% of the total weight of ammonium perchlorate. One of the rare earth metals is gadolinium.

[0097] It is prepared as: NH in the ratio of the amount of substance in gadolinium chloride solution 4 HCO 3 :GdC1 3 =2.8 Add ammonium bicarbonate solution for precipitation, heat-age the obtained gadolinium carbonate suspension in a water bath at 50°C for 4 hours to make gadolinium carbonate become crystalline precipitate, continue to add ammonium bicarbonate solution under stirring until gadolinium precipitation is complete , continued to age for 30 minutes, filtered, washed, and calcined at 800°C for 1 hour to obtain gadolinium oxide.

[0098] According to Gd 2 o 3 Consumption is 5% of the total weight of ammonium perchlorate, Gd 2 o 3 Mix evenly with the ammonium perchlorate granules prepared in Example 1.

Embodiment 3

[0100] In this example, ammonium perchlorate granules were prepared according to Example 1, and nitrocellulose was coated on the outside of the granules. Wherein the mass of nitrocellulose accounts for 0.02% of the total mass of the reagent.

[0101] Described nitrocellulose is coated outside ammonium perchlorate particle according to following method:

[0102] (1) Add nitrocellulose to silane coupling agent KH-550 to prepare a solution with a mass percentage of 3%, then add a mixed solution of ethanol and acetone, the volume ratio of ethanol and acetone is 1:1, stir evenly, and fully dissolve After obtaining the nitrocellulose solution, the volume ratio of the mixed solution of ethanol and acetone to the silane coupling agent solution of the nitrocellulose is 1:25;

[0103] (2) Add the dried ammonium perchlorate granules and the nitrocellulose solution prepared in step (1) into a kneader for thorough mixing at 20°C, and then dry them in an oven at 30-40°C for 24-28 hours to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com