Carbon fiber electric atomizing ionization device and method for realizing electric atomizing ionization by using device

An electrospray ionization and carbon fiber technology, applied in the field of mass spectrometry analysis, can solve problems such as unseen carbon fibers, and achieve the effects of suppressing the influence of the measurement, simplifying the sampling operation, and having strong universality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

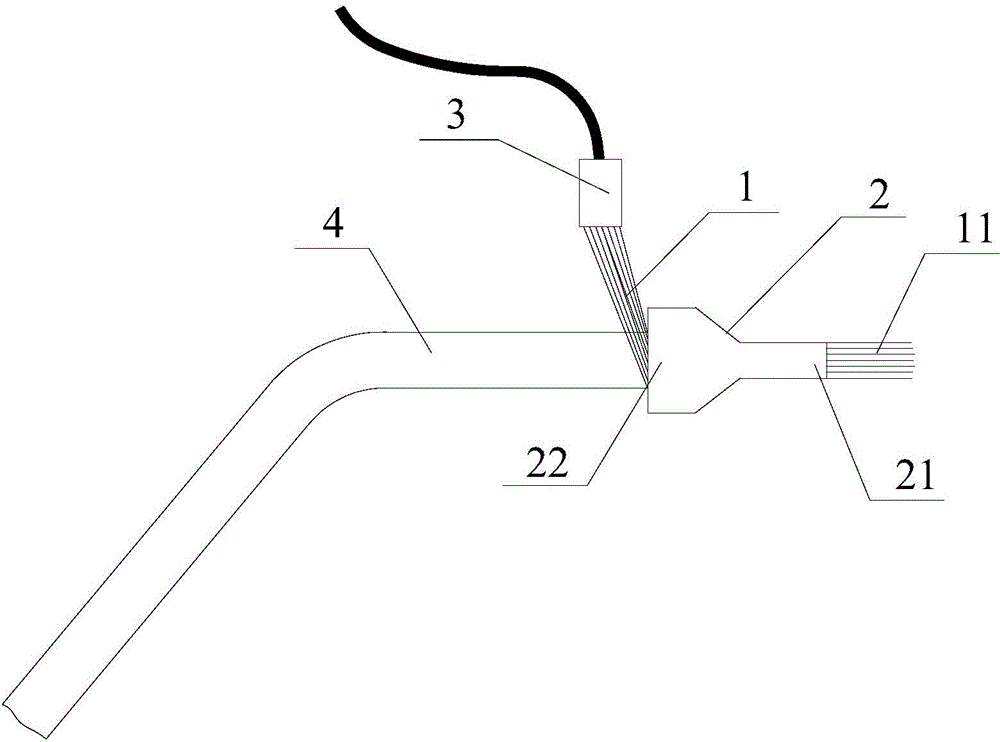

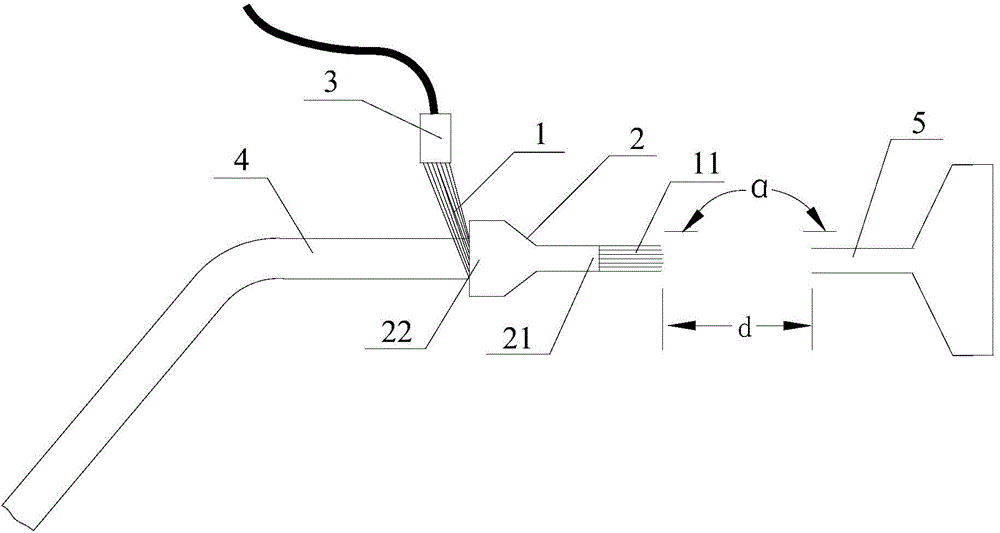

Method used

Image

Examples

Embodiment 1

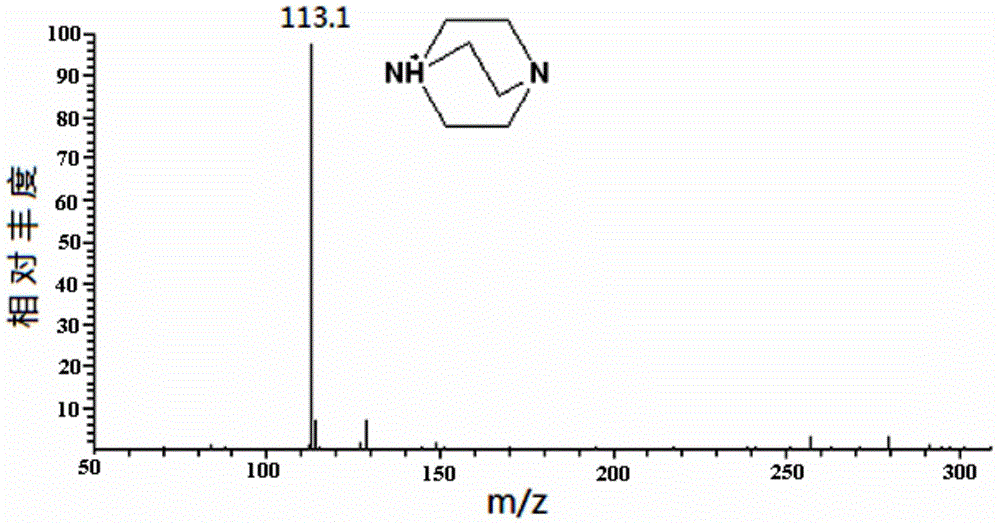

[0055] Adopt carbon fiber electrospray ionization device of the present invention and mass spectrometer (mass analyzer is a triple quadrupole) to nitrogen-containing compound 1,4-diazabicyclo[2.2.2]octane (DABCO): Perform mass spectrometry:

[0056] Use a mixed solvent of methanol and water with a volume ratio of 1:1 to configure DABCO into a sample solution to be tested at about 0.1 mg / mL; make the sampling and electrospray end 11 directly dip into the sample solution, and at the same time inject the solvent acetonitrile through the injection pump Lead the solvent / sample introduction channel 4 to the sampling and electrospray end 11 at a flow rate of 2 to 5 μL / min; turn on the power supply, and gradually increase the voltage to the ionization voltage of the electrospray, so that the sampling and electrospray end 11 performs electrospray desorption. Solvent, forming sample ions for mass spectrometry analysis.

[0057] Depend on image 3 Shown mass spectrogram is visible: in...

Embodiment 2

[0059] Adopt carbon fiber electrospray ionization device of the present invention and mass spectrometer (mass analyzer is a triple quadrupole) to slightly soluble small polar compound anisidine: Perform mass spectrometry:

[0060] Use CH 2 Cl 2 Configure anisidine to be about 0.1 mg / mL of the sample solution to be tested; use a pipette to pipette 2 μL and drop it to the sampling and electrospray port 11; Perform electrospray desolvation with the electrospray end 11 to form sample ions for mass spectrometry analysis.

[0061] Depend on Figure 4 The shown mass spectrogram can be seen: in the spectrogram, except the ion peak (m / z) 124 related to the compound, there is no interference of other impurity ion peaks, which shows that the device and method of the present invention are used for the non-conductivity of poor conductivity. Test compounds in polar solvents also have good ionization efficiencies.

Embodiment 3

[0063] Adopt carbon fiber electrospray ionization device of the present invention and mass spectrometer (mass analyzer is a triple quadrupole) to steroidal compound dehydroepiandrosterone: Perform mass spectrometry:

[0064] Use ethanol to configure dehydroepiandrosterone into a sample solution to be tested at about 0.1 mg / mL; use a pipette to pipette 2 μL and drop it to the sampling and electrospray port 11; turn on the power to gradually increase the voltage to the electrospray The ionization voltage enables the sampling and electrospray end 11 to perform electrospray desolvation to form sample ions for mass spectrometry analysis.

[0065] Depend on Figure 5 The mass spectrogram shown can be seen: in the spectrogram, except for ion peaks (m / z) 271 and 289 (respectively proton peak and proton dehydration peak of the target compound) related to the compound, there is no interference from other impurity ion peaks , indicating that the device and method of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com