High pressure resistant nitride semiconductor epitaxial structure and growing method thereof

A technology of nitride semiconductor and epitaxial structure, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of reducing heterojunction channel mobility and two-dimensional electron gas carrier concentration, and reducing GaN crystal Quality, increase surface roughness and other issues, to achieve the effect of reducing epitaxial growth time, reducing production costs, and improving stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

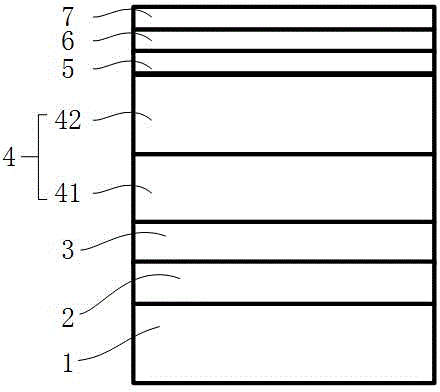

[0040] Such as figure 1 Shown is a schematic diagram of the epitaxial structure of this embodiment, including a substrate 1, a nucleation layer 2, an impurity filter layer 3, a compound nitride epitaxial buffer layer 4, an electron blocking layer 5, an undoped gallium nitride channel layer 6 and Heterojunction barrier layer 7. The composite nitride epitaxial buffer layer 4 includes a high-resistance aluminum-rich nitride stress buffer layer 41 and a high-resistance top layer gallium nitride buffer layer 42 on the high-resistance aluminum-rich nitride stress buffer layer 41 .

[0041] The growth method used in this solution is one of two methods: molecular beam epitaxy or metal organic chemical vapor deposition.

[0042] The above method for manufacturing a high withstand voltage nitride semiconductor epitaxial structure is as follows: figure 1 shown, including the following steps:

[0043] (1) A nucleation layer 2 is grown on the substrate 1 by molecular beam epitaxy or met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com