A continuous flow anaerobic biocathode microbial fuel cell

A fuel cell and anaerobic biological technology, applied in the field of environmental protection technology and new energy, can solve the problems of unfavorable volume, unsuitable hydraulic conditions for continuous inflow of water, unsuitable for continuous removal of oxidative pollutants in water, etc., so as to reduce pressure , to ensure the effect of long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

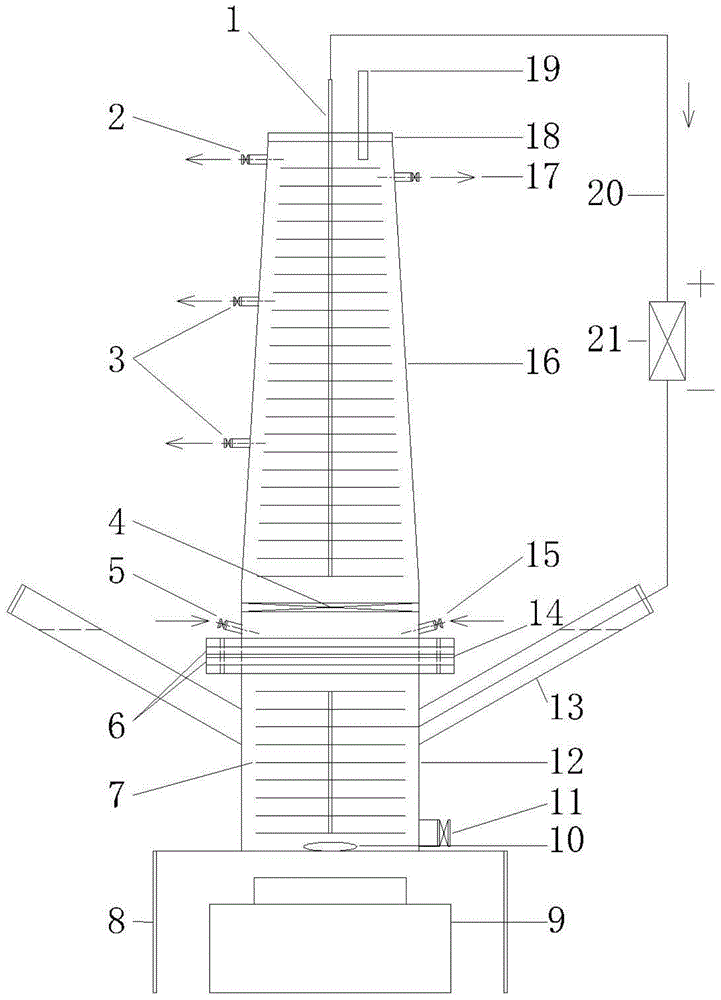

[0030] The simulated groundwater containing nitrate, bromate and selenate is treated by using the anaerobic biocathode microbial fuel cell of the present invention.

[0031] The volume ratio of the cathode chamber 16 and the anode chamber 12 in this embodiment is 2:1, and both the cathode electrode 1 and the anode electrode 7 are graphite fiber brushes.

[0032] The cathode chamber 16 in this embodiment is a truncated cone with a large lower surface, and the ratio of the area of the lower surface to the area of the upper surface is 1.5:1.

[0033] The mud inlet 13 of the anode chamber in this embodiment forms an angle of 45° with the horizontal line, and the liquid level of the anolyte therein is higher than the cation exchange membrane.

[0034] In this embodiment, the backflow inlet 5 and the water inlet 15 form an angle of 30° with the horizontal line.

[0035] The load 21 referred to in this embodiment refers to a resistance box set to 1000 ohms.

[0036] The sludge ...

Embodiment 2

[0041] The anaerobic biological cathode microbial fuel cell of the present invention is used to treat steel rolling wastewater containing nitrate.

[0042] Steel rolling wastewater contains a large amount of nitrate. At present, most enterprises adopt reverse osmosis process for wastewater reuse process. The reverse osmosis process will produce about 30% concentrated brine, and the nitrate in the concentrated brine will be concentrated 3-4 times, reaching 50- 100mg / L, and very little carbon source.

[0043] The volume ratio of the cathode chamber 16 and the anode chamber 12 in this embodiment is 3:1, and both the cathode electrode 1 and the anode electrode 7 are carbon felts.

[0044] The cathode chamber 16 in this embodiment is a truncated cone with a large lower surface, and the ratio of the area of the lower surface to the area of the upper surface is 2:1.

[0045] The mud inlet 13 of the anode chamber in this embodiment forms an angle of 45° with the horizontal line, an...

Embodiment 3

[0053] The simulated wastewater containing dichromate is treated by using the anaerobic biocathode microbial fuel cell of the invention.

[0054] Chromium-containing waste water is produced in mineral processing, smelting, electroplating, printing and dyeing, leather and inorganic salt production and other industrial processes. Among the chromium compounds, hexavalent chromium is the most toxic, followed by trivalent chromium, divalent chromium and chromium itself have little or no toxicity.

[0055] The volume ratio of the cathode chamber 16 and the anode chamber 12 in this embodiment is 5:1, and both the cathode electrode 1 and the anode electrode 7 are made of carbon cloth.

[0056] The cathode chamber 16 in this embodiment is a truncated cone with a relatively large lower surface, and the ratio of the area of the lower surface to the area of the upper surface is 3:1.

[0057] The mud inlet 13 of the anode chamber in this embodiment forms an angle of 45° with the horiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com