Two-component polyurethane putty for repairing vehicle body coating, and application method thereof

A two-component polyurethane and coating technology, applied in the direction of coating, device for coating liquid on the surface, filling slurry, etc., can solve the problems of low delivery efficiency, high labor cost, harmful to health, etc. The effect of emission, reduction of construction links, and improvement of delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

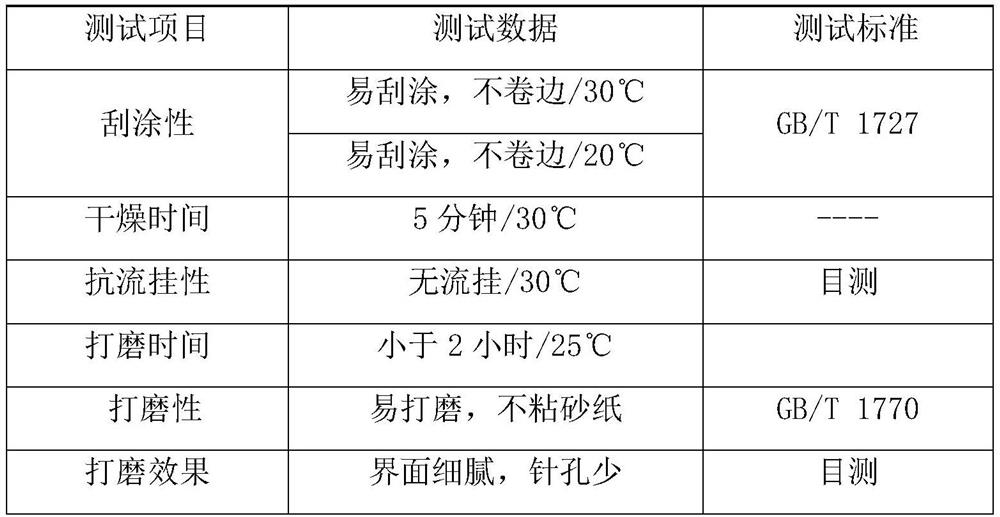

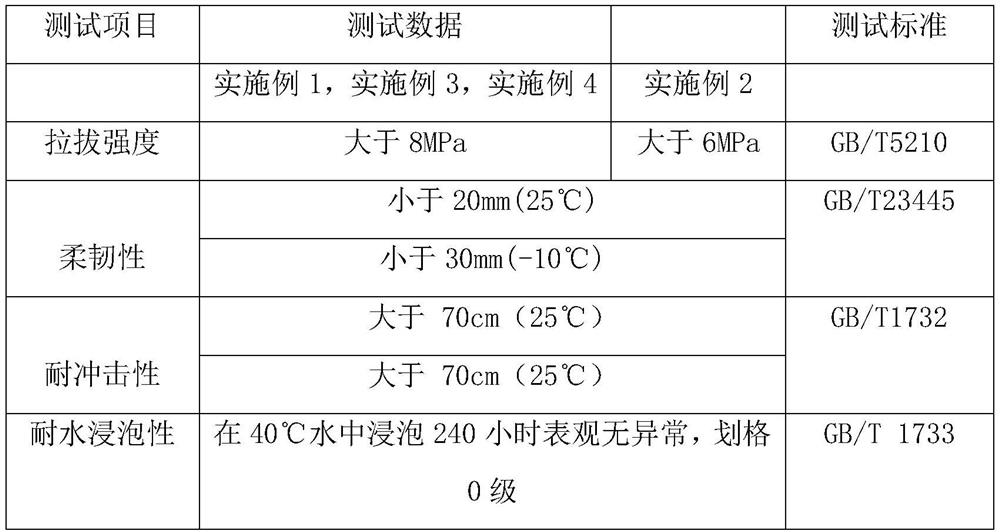

Examples

Embodiment 1

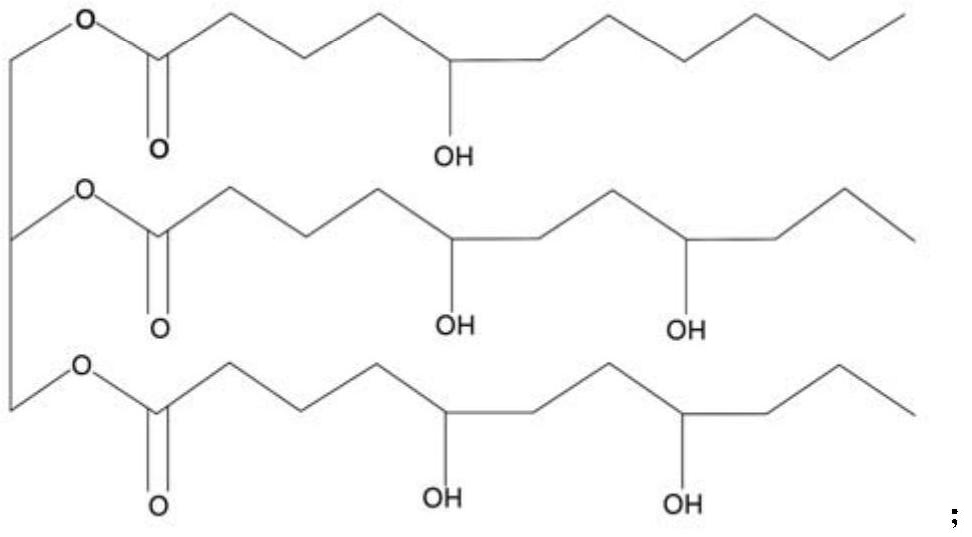

[0039] 120g molecular weight is 1400-1600 soybean oil-based polyol (SD-430, Shanghai Gaowei Industrial Co., Ltd.), 50g molecular weight is 800-900 soybean oil-based polyol (SD-250, Shanghai Gaowei Industrial Co., Ltd.), 300g calcium carbonate, 400g talcum powder, 10g thixotropic agent (fumed silica), 5g wetting and dispersing agent (BYK-9076), 10g defoamer (TEGO900), 0.5g diisobutyltin laurate, 30g 4A molecular sieve Activation powder, 10g of silane coupling agent, and 32g of hollow glass spheres were stirred and mixed evenly at a high speed under the condition of 80-100°C to obtain component A for later use;

[0040] Stir and mix component A and component B (HDI trimer) at room temperature at a weight ratio of 8:1 to obtain a mixture that is a two-component polyurethane putty.

Embodiment 2

[0042] 170g castor oil-based polyol (Uric H-30), 300g calcium carbonate, 400g talcum powder, 12g thixotropic agent (fumed silica), 6g wetting and dispersing agent (BYK-9076), 8g defoamer (Digo TEGO900), 0.5g of diisobutyltin laurate, 30g of 4A molecular sieve activation powder, 10g of silane coupling agent, and 28g of hollow glass spheres were stirred and mixed evenly at a high speed under the condition of 80-100°C to obtain component A for later use;

[0043] Stir and mix component A and component B (HDI trimer) at room temperature at a weight ratio of 8:1 to obtain a mixture that is a two-component polyurethane putty.

Embodiment 3

[0045] 100g soybean oil-based polyol (SD-430, Shanghai Gaowei Industrial Co., Ltd.) with a molecular weight of 1400-1600, 500g calcium carbonate, 0.50g thixotropic agent (BYK-410), 8g wetting and dispersing agent (BYK-9076) , 8g defoamer (TEGO900), 1g stannous octoate, 38g4A molecular sieve activation powder, 8g silane coupling agent, 40g hollow glass spheres were mixed evenly at high speed under the condition of 80-100°C to obtain component A for later use;

[0046] Stir and mix component A and component B (HDI biuret) at room temperature at a weight ratio of 10:1 to obtain a mixture that is a two-component polyurethane putty.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com