Silicone-modified vegetable oil polymer polyether defoamer and preparation method thereof

A technology of siloxane modification and polymer polyether, which is applied in the direction of foam dispersion/prevention to achieve the effects of improving stability, improving dispersibility and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

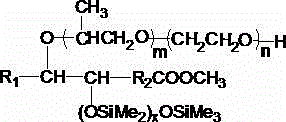

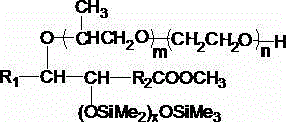

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Prepare silicone modified vegetable oil polymer polyether defoamer according to the following steps

[0021] (1) Add a mixture of 1 kg epoxy soybean oil and hydroxyl-terminated silicone oil with a viscosity of 20cst (the molar ratio of epoxy group to silicone oil in soybean oil is 1:1), and 1 g of fluoroboric acid into the reactor. Stir and heat to 90°C, react for 2 hours, cool to room temperature, extract the reaction mixture with dichloromethane, and then wash the organic layer three times with saturated sodium chloride solution, after separation, the organic layer is distilled off under reduced pressure to obtain silicon Oxyalkylene modified vegetable oil polyols;

[0022] (2) Put 1 kg of the siloxane-modified vegetable oil polyol prepared in step (1) into a three-necked flask, slowly add 200 mL of 2.5 mol / L potassium hydroxide methanol solution dropwise at 60 ° C, and keep it warm for about 1 hour after the dropping is completed. Stopping the reaction...

Embodiment 2

[0024] Embodiment 2: prepare siloxane modified vegetable oil polymer polyether defoamer according to the following steps

[0025] (1) Add a mixture of 1 kg epoxy soybean oil and hydroxyl-terminated silicone oil with a viscosity of 100cst (the molar ratio of epoxy group to silicone oil in soybean oil is 1:1.1), and 1.5 g of fluoroboric acid into the reactor, under nitrogen protection Stir and heat to 95°C, react for 2 hours, cool to room temperature, extract the reaction mixture with dichloromethane, then wash the organic layer three times with saturated sodium chloride solution, and after separation, the organic layer is distilled off under reduced pressure to obtain silicon Oxyalkylene modified vegetable oil polyols;

[0026] (2) Put 1 kg of the siloxane-modified vegetable oil polyol prepared in step (1) into a three-necked flask, slowly add 300 mL of 2.5 mol / L potassium hydroxide methanol solution at 60 ° C, and keep it warm for about 1 hour after the addition is completed. ...

Embodiment 3

[0028] Embodiment 3: Prepare silicone modified vegetable oil polymer polyether defoamer according to the following steps

[0029] (1) Add a mixture of 1 kg epoxy soybean oil and hydroxyl-terminated silicone oil with a viscosity of 1000cst (the molar ratio of epoxy group to silicone oil in soybean oil is 1:1.2), and 2 g of fluoroboric acid into the reactor. Stir and heat to 100°C, react for 2 hours, cool to room temperature, extract the reaction mixture with dichloromethane, then wash the organic layer three times with saturated sodium chloride solution, and remove the solvent from the organic layer by vacuum distillation to obtain silicon Oxyalkylene modified vegetable oil polyols;

[0030] (2) Put 1 kg of the siloxane-modified vegetable oil polyol prepared in step (1) into a three-necked flask, slowly add 400 mL of 1.25 mol / L potassium hydroxide methanol solution at 60°C, and keep it warm for about 1 hour after the addition is complete. Stopping the reaction, washing the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com