Bio-adhesion-resistant porous separation membrane as well as preparation method and application thereof

A porous separation membrane, anti-biological technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the complex preparation method, high price of zwitterionic monomers, and harsh polyethersulfone sulfonation process. problem, to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

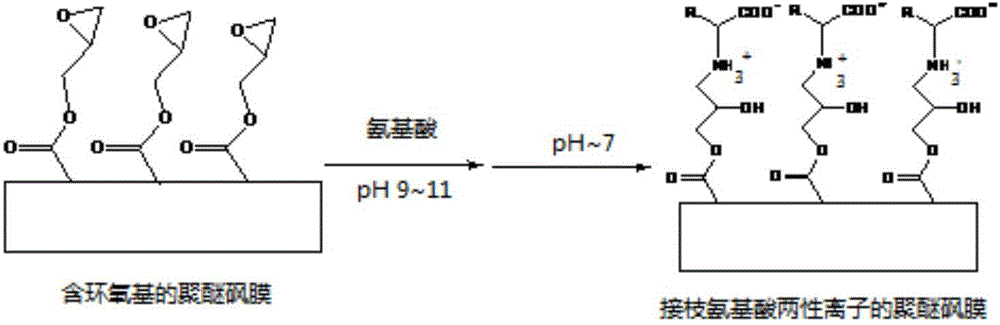

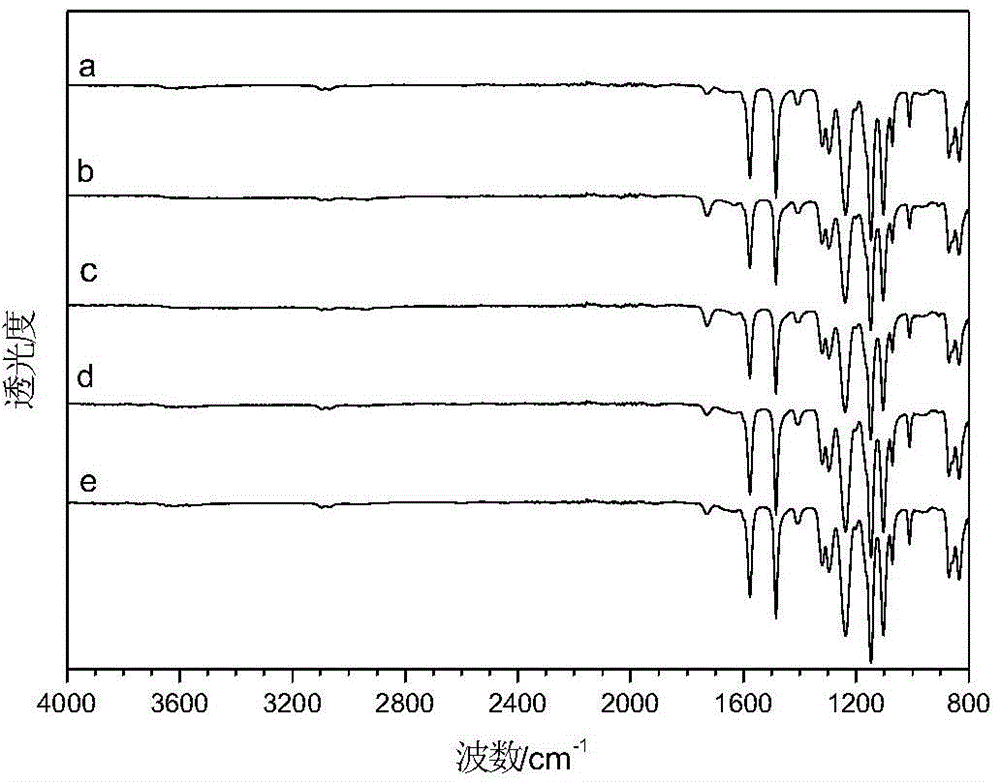

[0027] The preparation method of the anti-bioadhesion porous separation membrane: the polymer porous membrane containing epoxy groups on the surface is soaked in the solution containing amino acids, and the epoxy ring-opening reaction is carried out under the alkaline condition of pH 8-13, and the temperature is 20 The reaction is carried out at 0°C to 100°C for 0.5 hours to 24 hours, and then the pH is adjusted to 5-9 to obtain an anti-bioadhesion porous separation membrane of amino acid zwitterions containing amino cations and carboxylate anions on the surface.

[0028] The application of the anti-bioadhesion porous separation membrane in separation and purification is to package the anti-bioadhesion porous separation membrane together with the shell and process it into a complete separation system for water purification, chemical separation and purification, drug separation and purification, and hemodialysis.

[0029] A kind of anti-bioadhesion porous separation membrane of ...

Embodiment 1

[0044] Embodiment 1 (comparative example)

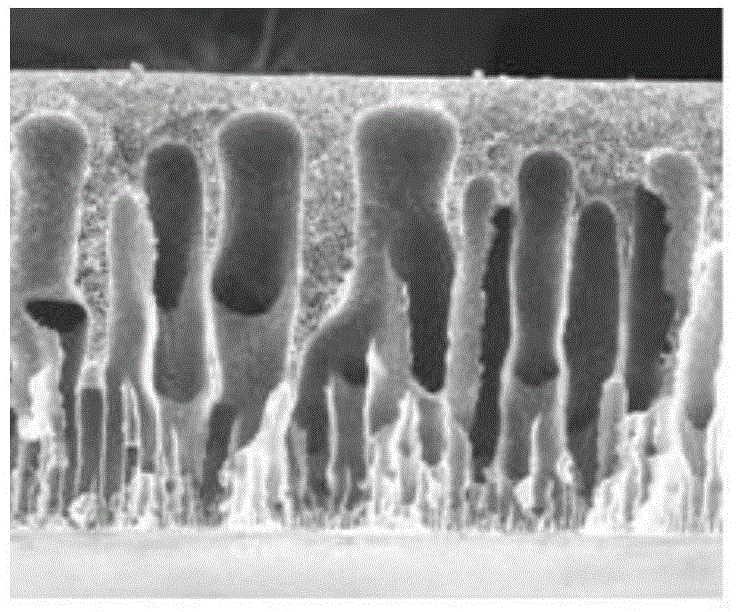

[0045] Preparation of polyethersulfone separation membrane

[0046] Polyethersulfone and polyvinylpyrrolidone were vacuum-dried at 60°C for 12 hours before use. Weigh 10g of N,N-dimethylacetamide, weigh 0.2g of polyvinylpyrrolidone and dissolve it in N,N-dimethylacetamide at room temperature, wait until it is completely dissolved, weigh 1.6g of polyethersulfone and dissolve it in the mixed solution , fully stir to form a transparent and uniform casting solution, let it stand for 4 hours for degassing, pour the casting solution on a glass plate to scrape the film, place it in the air for 10-30 seconds, then put in water and isopropanol to solidify The film is formed in the bath, the volume ratio of water and isopropanol is 3:7, the film thickness is 200 μm, and soaked in deionized water for 24 to 36 hours to obtain the original polyethersulfone separation membrane with a porosity of 63%.

[0047] The obtained polyethersulfone separa...

Embodiment 2

[0049] Preparation of polyethersulfone porous membrane containing epoxy groups on the surface (comparative example)

[0050] Polyethersulfone and polyvinylpyrrolidone were vacuum-dried at 60°C for 12 hours before use. Weigh 1 g of N,N-dimethylacetamide into a 50 mL beaker, add 0.24 g of glycidyl methacrylate, 0.0016 g of 2-hydroxy-2-methyl-1-phenyl-1 acetone and 0.0016 g Ethylene glycol dimethacrylate, ultrasonically oscillate for 5 minutes until uniformly mixed; place the beaker under ultraviolet light with a wavelength of 365nm for 1 hour to obtain a mixed solution containing polyglycidyl methacrylate, and then add the mixed solution Add 9 grams of N,N-dimethylacetamide to the mixture, stir the mixture, weigh 0.08 grams of polyvinylpyrrolidone with a molecular weight of 300,000 as a porogen, add it to the mixture, stir at room temperature for 20 minutes until completely dissolved, and then add 1.6 grams Polyethersulfone, stir at room temperature for about 6 hours, mix evenl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com