Preparation method of wavelength adjustable fluorescent carbon dot and application of fluorescent carbon dot in mercury ion detection

A technology of fluorescent carbon dots and mercury ions, applied in fluorescence/phosphorescence, chemical instruments and methods, luminescent materials, etc., can solve the problems of low quantum yield, achieve simple synthesis methods, easy control of reaction conditions, and good repeatability of results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the wavelength-tunable fluorescent carbon dot proposed by the present invention comprises the following steps:

[0025] (1) adding valine to 10 milliliters of water so that the mass percent concentration of valine is 0.2% to 30%, place it on a magnetic stirrer, stir to fully dissolve valine, and obtain an aqueous solution of valine;

[0026] (2) Add 1 to 10 milliliters of concentrated phosphoric acid into the valine aqueous solution of step (1), and continue stirring until the solution is a uniformly dispersed solution;

[0027] (3) Put the uniformly dispersed solution of step (2) into a hydrothermal reaction kettle, move it into an oven for pyrolysis reaction, the reaction temperature is 100°C-120°C, and the reaction time is 2-24 hours to obtain a crude product;

[0028] (4) or put the uniformly dispersed solution of step (2) into a constant temperature water bath, place it on a magnetic stirrer to stir and react, the reaction temperature is 6...

Embodiment 1

[0039] (1) 1 gram of valine is added to 10 milliliters of concentrated phosphoric acid, placed on a magnetic stirrer, fully stirred so that valine is fully dissolved, and a uniformly dispersed solution is obtained;

[0040] (2) Put the solution obtained in step (1) into a hydrothermal reaction kettle, move it into an oven for pyrolysis reaction, the reaction temperature is 120° C., and the reaction time is 4 hours to obtain a crude product;

[0041] (3) After the crude product of step (3) is neutralized with 1 mole per liter of sodium oxide solution, the precipitate is removed through a 0.22 micron microporous membrane to obtain an aqueous solution of blue fluorescent carbon dots.

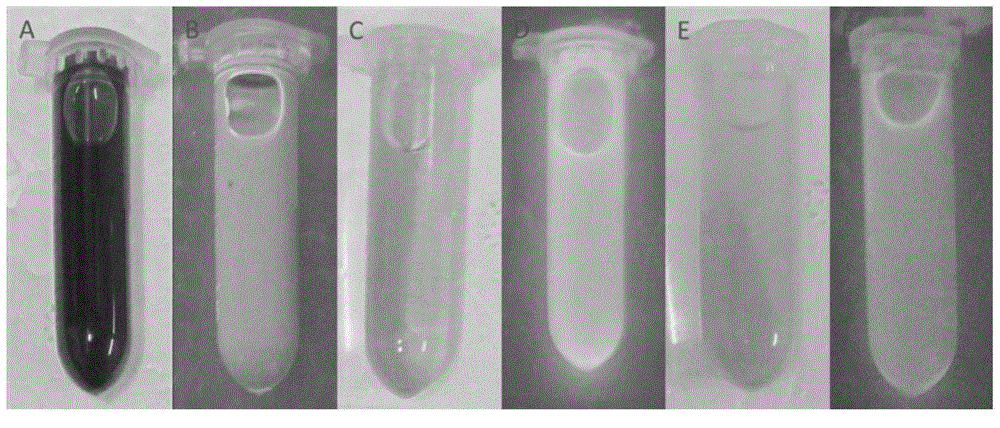

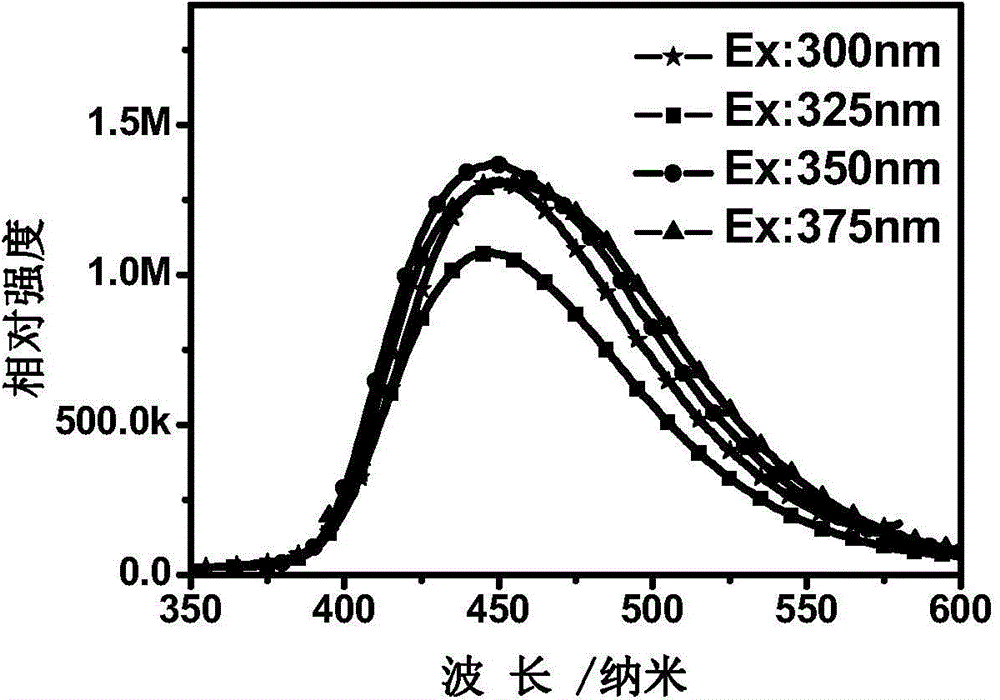

[0042] The photoluminescence property characterization of gained carbon dot: irradiate the carbon dot aqueous solution sample with the ultraviolet lamp of wavelength 365 nanometers, can observe obvious blue fluorescence, as figure 1 As shown in B, figure 1 A is a photo of the sample under indoor w...

Embodiment 2

[0044] (1) Add 1 gram of valine to 10 milliliters of water, place on a magnetic stirrer, and stir until the valine is fully dissolved to obtain a 10% valine aqueous solution;

[0045] (2) 2 milliliters of concentrated phosphoric acid are added in the solution obtained in step (1), and continue to stir until the solution is a uniformly dispersed solution;

[0046] (3) Put the solution obtained in step (2) into a constant temperature water bath, place it on a magnetic stirrer to stir the reaction, the reaction temperature is 90° C., and the reaction time is 4 hours to obtain the crude product;

[0047] (4) After the crude product of step (3) is neutralized with 1 mole per liter of sodium hydroxide solution, the precipitate is removed by a 0.22 micron microporous membrane to obtain an aqueous solution of green fluorescent carbon dots.

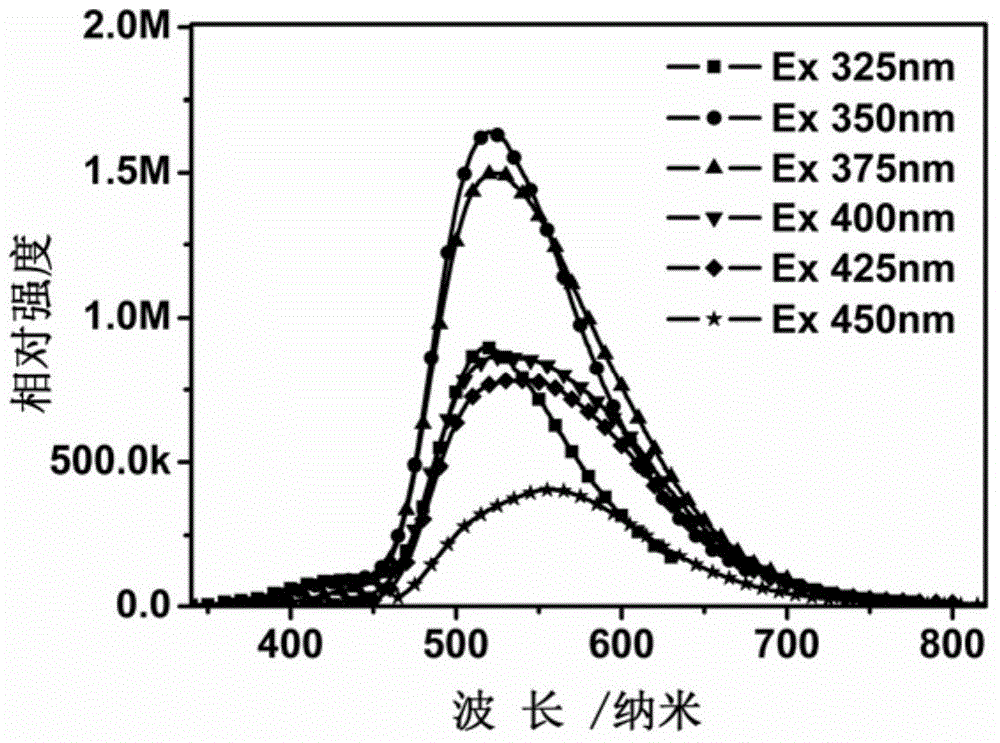

[0048] The photoluminescence property characterization of gained carbon dot: irradiate the carbon dot aqueous solution sample with the ultraviole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com