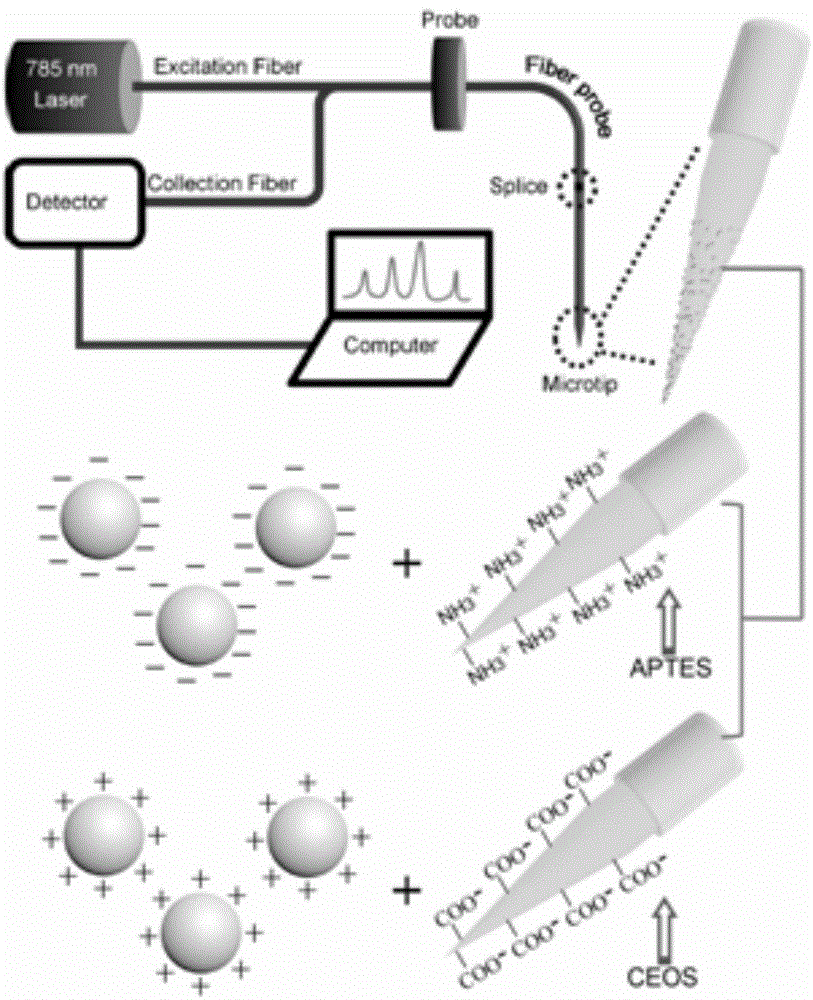

Method for assembling precious metal nanocrystalline on surface of conical fiber

A noble metal nanocrystal, tapered optical fiber technology, applied in the field of optical fiber, can solve the problems of limiting the sensitivity of detection of pollutants, unable to control the morphology of nanostructures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) First put 48 mg of silver nitrate and 48 mg of polyvinylpyrrolidone in 3 mL of pentylene glycol, the mass ratio of the three is about 1:1:60, and stir at room temperature until completely dissolved, then 0.8-1.2mg / mL sodium chloride ethylene glycol solution is mixed with it evenly, so that the mass ratio of silver nitrate and sodium chloride is 400:1, and the pentylene glycol solution of silver nitrate and PVP-k29 is obtained;

[0056] Put 5 ml of pentanediol as a reaction precursor in a 50 ml round-bottomed flask at 150 o C in methyl silicone oil for 1 hour, the bottle mouth of the round bottom flask was covered with a rubber stopper with a through hole, and the stirring rate was maintained at 500 RPM. Then, the pentanediol solution of silver nitrate and PVP-k29 was injected with The pump injected at a rate of 600 μL / min to 140 o In 5 mL of pentylene glycol solvent at C, react for 3 hours. After the reaction, maintain the stirring rate of the reaction solution un...

Embodiment 2

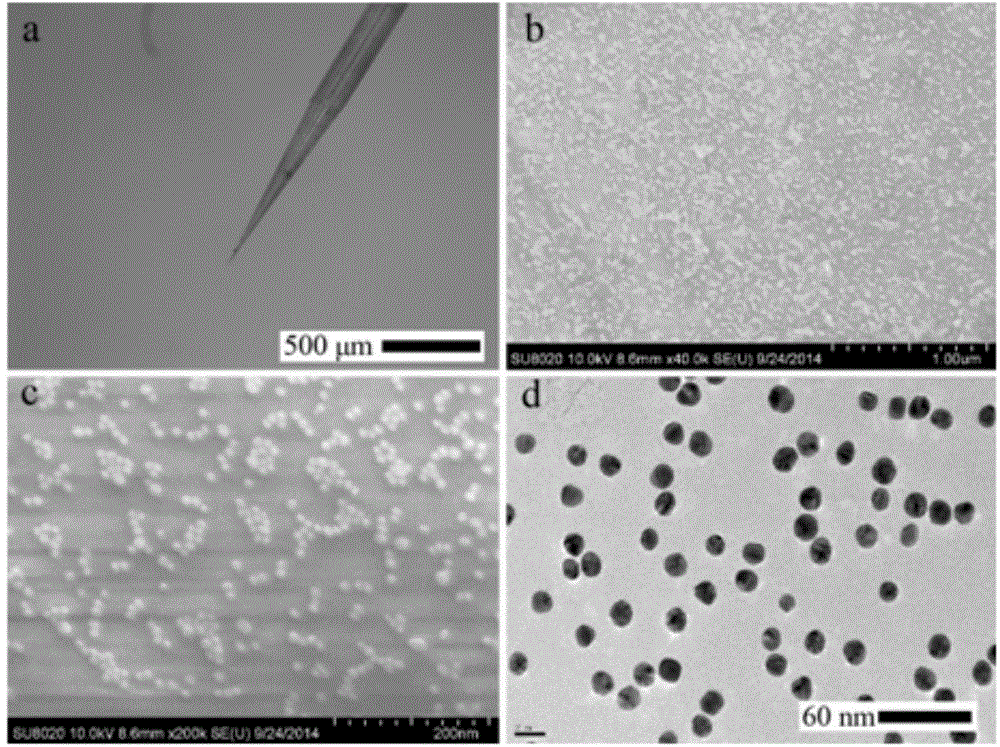

[0062] (1) First prepare 10 g / L sodium citrate aqueous solution and 5 g / L chloroauric acid aqueous solution, then inject 1000 μL sodium citrate aqueous solution into 90 o C into 50 mL of water, and 200 μL of chloroauric acid was added dropwise. The round-bottomed flask used for the reaction was placed in a water bath to maintain the temperature. The entire reaction time was maintained for 30 minutes, and finally a sodium citrate-protected sodium citrate with a diameter of about 13 nm was obtained. Suspensions of negatively charged gold nanospheres;

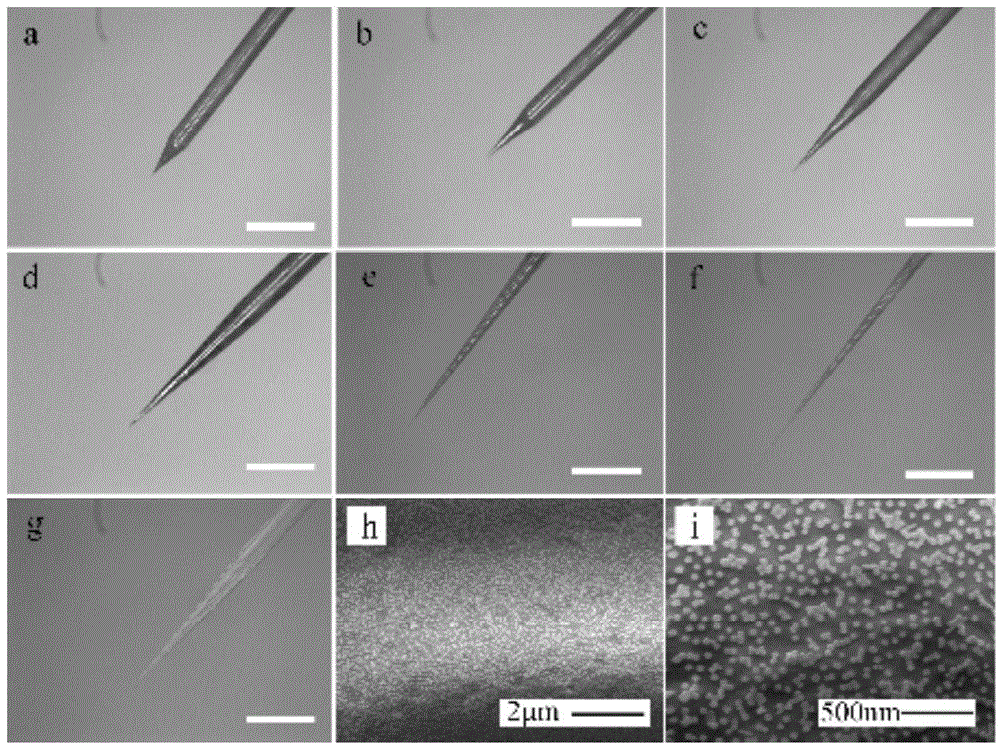

[0063] (2) Strip off the coating layer at the end of the multimode fiber with a blade, insert it into 40 wt% hydrofluoric acid, seal it with methyl silicone oil, and use a puller to slowly pull the fiber vertically at a rate of 19.4 μm / min,;

[0064] When the silicon oxide at the end of the optical fiber is corroded by hydrofluoric acid, the end forms a tapered structure with a cone angle of 3.6 o ; The core diameter of the mul...

Embodiment 3

[0068] (1) Dissolve 0.01 M in 0.25 mL HAuCl 4 and 0.6 mL of NaBH at 0.01 M 4 Add to 9.75 mLCTAB of 0.1 M in sequence, and then stir for two minutes at a speed of 700-900 rpm under a magnetic stirrer. o The constant temperature water tank of C was left standing for two hours as a seed solution;

[0069] Next, add 0.01 M of 0.25 mL HAuCl 4 , 0.01 M in 0.4 mL of AgNO 3 and 0.8 mL of 1.0 M HCl were added to 40 mL of 0.1 M CTAB in sequence. At this time, the solution was light yellow. After shaking evenly, 0.32 mL of 0.1 M ascorbic acid AA was added, and the solution became colorless after shaking slightly for 30 seconds. Then add 0.096 mL of pre-prepared seed solution, shake slightly for 30 seconds, and place at 28 o Stand still in the constant temperature water tank of C for 12 hours, finally form the suspension of positively charged gold nanorods protected by CTAB;

[0070] (2) Strip the cladding layer at the end of the multimode fiber with a blade, insert it into 40 wt% hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Core diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com