Light emitting diode using ITO regional sheet resistance change to improve current spreading and manufacturing method

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of high cleanliness requirements for epitaxial layers, difficult epitaxial growth, and increased difficulty, so as to improve the uniformity of current expansion and improve the current Effect of expansion and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

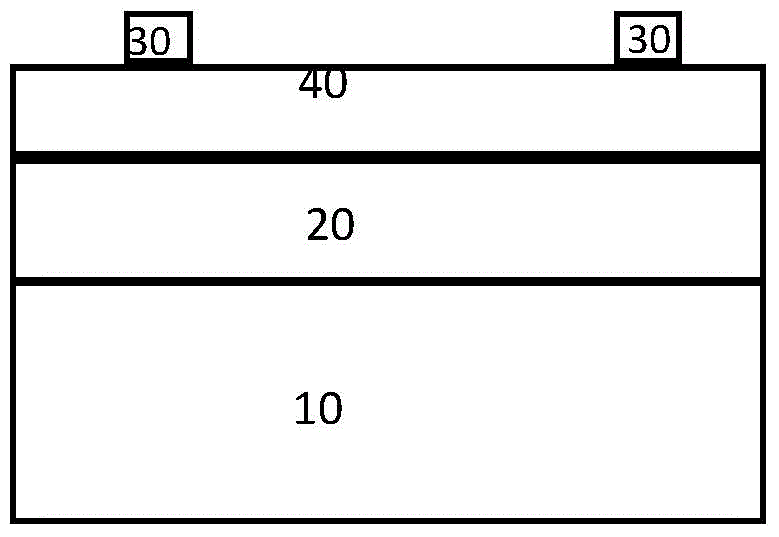

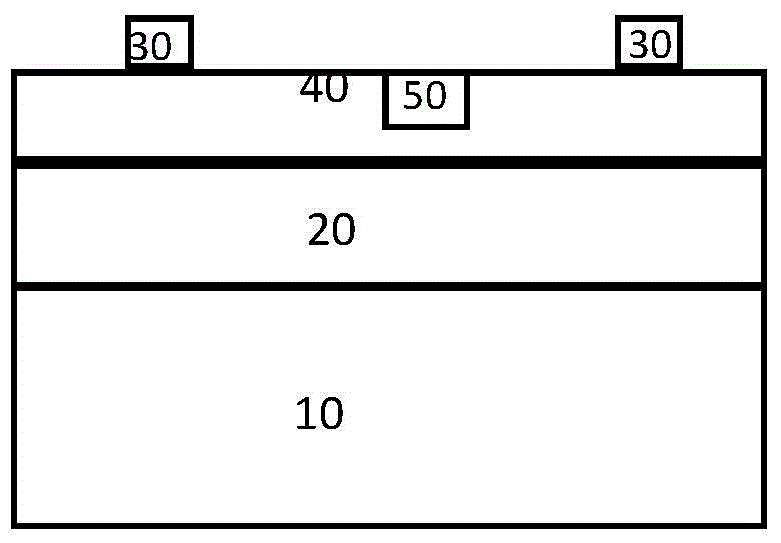

[0052] Embodiment 1. A method for improving the current spreading of light-emitting diodes by utilizing ITO regional square resistance changes, the described light-emitting diode structure includes an epitaxial wafer grown on a substrate 10, an ITO thin film 40 positioned on the epitaxial wafer, and a metal electrode 60 and passivation layer 70. Among them, the ITO film is made into three regions with different square resistance, low square resistance ITO region I, medium square resistance ITO region II and high square resistance ITO region III, and the square resistance of the low square resistance ITO region I is 5-10 ohms / square; the square resistance of ITO area II of the middle square resistance is 10-15 ohms / square; the square resistance of the high square resistance ITO area III is 50-70 ohms / square. The high square resistance ITO region III is located under the metal electrode, the area is smaller than the metal electrode pattern, and is 5-8 microns smaller than the ...

Embodiment 2

[0053] Embodiment 2. A light-emitting diode with improved current spreading and its manufacturing method

[0054] Step 1: Preparation of LED Epitaxial Wafer

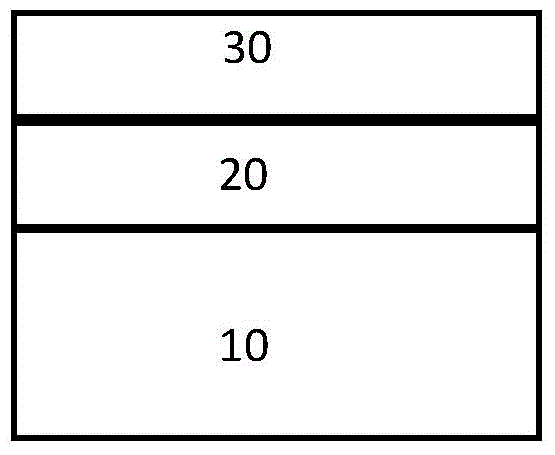

[0055] The epitaxial wafer includes GaN-based blue LED or AlGaInP quaternary red LED epitaxial wafer; the main structure of the epitaxial wafer includes a substrate 10 and an epitaxial layer 20 . Wherein the substrate is selected from sapphire, gallium arsenide, silicon or silicon carbide; the epitaxial layer includes a buffer layer, an N-type layer, a multiple quantum well, and a P-type layer;

[0056] Step 2: Growth of ITO film on the epitaxial wafer surface

[0057] Preparation of ITO thin films on the epitaxial layer, see figure 1 , the preparation method includes the use of secondary electron beam evaporation, plasma-assisted electron beam evaporation or magnetron sputtering, etc.; preferably, the electron beam evaporation ITO film 30, the evaporation rate is 1 to 1.5 angstroms / second, and the evaporation temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com