A kind of easy-to-wipe portable blackboard film and preparation method thereof

A portable and blackboard technology, applied in coating and other directions, can solve the problems of portable blackboards that are prone to paint peeling, cannot be separated from brackets, and are not easy to dry. rubbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

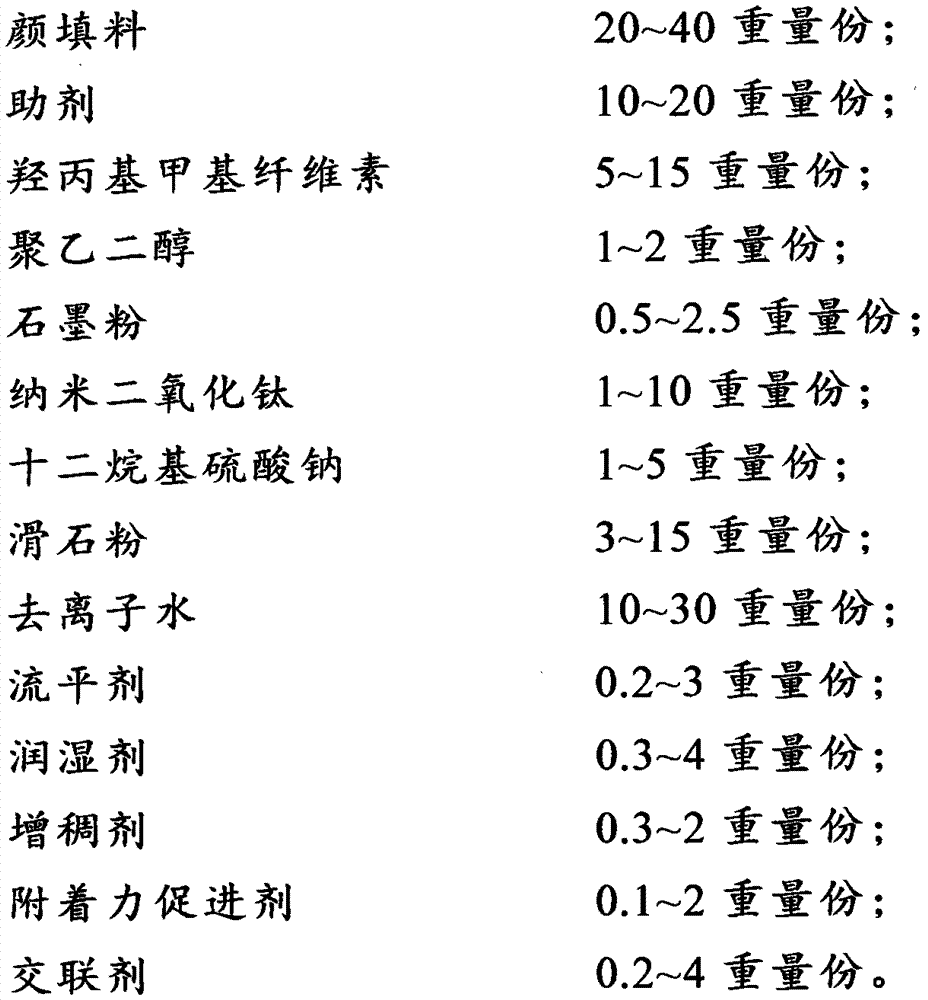

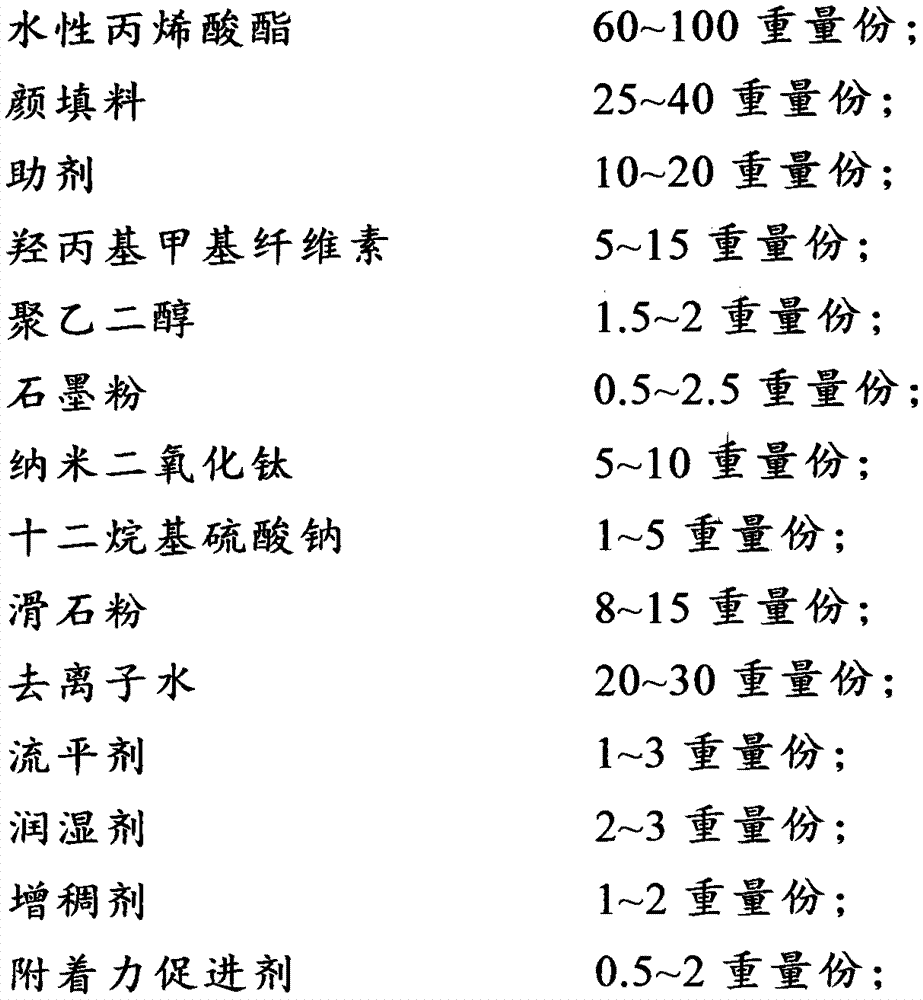

[0027] Correspondingly, the present invention also provides a preparation method of an easy-to-wipe portable blackboard film, comprising the following steps: mixing 10-30 parts by weight of deionized water and 10-20 parts by weight of additives, and adding 20-40 parts by weight of Pigment, 1-2 parts by weight of polyethylene glycol and 1-5 parts by weight of sodium lauryl sulfate, and then add 50-100 parts by weight of water-based acrylate to form a mixture; add 0.5-2.5 parts by weight of graphite to the mixture in sequence Powder, 1-10 parts by weight of nano titanium dioxide, 5-15 parts by weight of hydroxypropyl methylcellulose, 3-15 parts by weight of talc, 0.1-2 parts by weight of adhesion promoter, 0.2-4 parts by weight of crosslinking agent, 0.2-3 parts by weight of leveling agent, 0.3-4 parts by weight of wetting agent and 0.3-2 parts by weight of thickener are stirred to form a coating; the coating is applied to the surface of the substrate and dried to form an easy-to...

Embodiment 1

[0047] According to the weight of raw materials shown in Table 1, add deionized water and additives into the dispersion tank, stir evenly, add pigments and fillers, polyethylene glycol and sodium lauryl sulfate to mix and disperse, and then add water-based acrylate Mix well to form a mixture, add graphite powder, nano-titanium dioxide, hydroxypropyl methylcellulose, talcum powder, adhesion promoter, crosslinking agent, leveling agent, wetting agent, thickener to the mixture in turn and mix well , Stir evenly to make a coating with a predetermined viscosity.

[0048] Put the PP material in an oven and dry it at 100°C for 12 hours, put iron oxide magnetic powder, carbon black, glass fiber, phenyl o-hydroxybenzoate and dibutyl hydroxytoluene in the oven, and dry it at 80°C for 6 After drying, put PP, iron oxide magnetic powder, carbon black, glass fiber, phenyl o-hydroxybenzoate and dibutyl hydroxytoluene into the agitator, stir at 800r / h for 40min to fully mix, and mix evenly P...

Embodiment 2

[0051] According to the weight of raw materials shown in Table 1, add deionized water and additives into the dispersion tank, stir evenly, add pigments and fillers, polyethylene glycol and sodium lauryl sulfate to mix and disperse, and then add water-based acrylate Mix well to form a mixture, add graphite powder, nano-titanium dioxide, hydroxypropyl methylcellulose, talcum powder, adhesion promoter, crosslinking agent, leveling agent, wetting agent, thickener to the mixture in turn and mix well , Stir evenly to make a coating with a predetermined viscosity.

[0052] Put the PP material in an oven and dry it at 100°C for 12 hours, then add strontium-iron oxide magnetic powder, carbon black, glass fiber, 2-hydroxy-4-n-octyloxybenzophenone and tert-butyl terephthalate Phenol was placed in an oven and dried at 80°C for 6 hours. After drying, PP, strontium-iron oxide magnetic powder, carbon black, glass fiber, 2-hydroxy-4-n-octyloxybenzophenone and tert-butyl p- Put hydroquinone i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com