Stabilized phase change material for floor heating heat storage

A phase change material and floor heating technology, applied in heat exchange materials, chemical instruments and methods, building structures, etc., can solve the problems of lack of temperature adjustment function, long construction time, large thickness, etc., to reduce the occupied space , The effect of convenient construction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

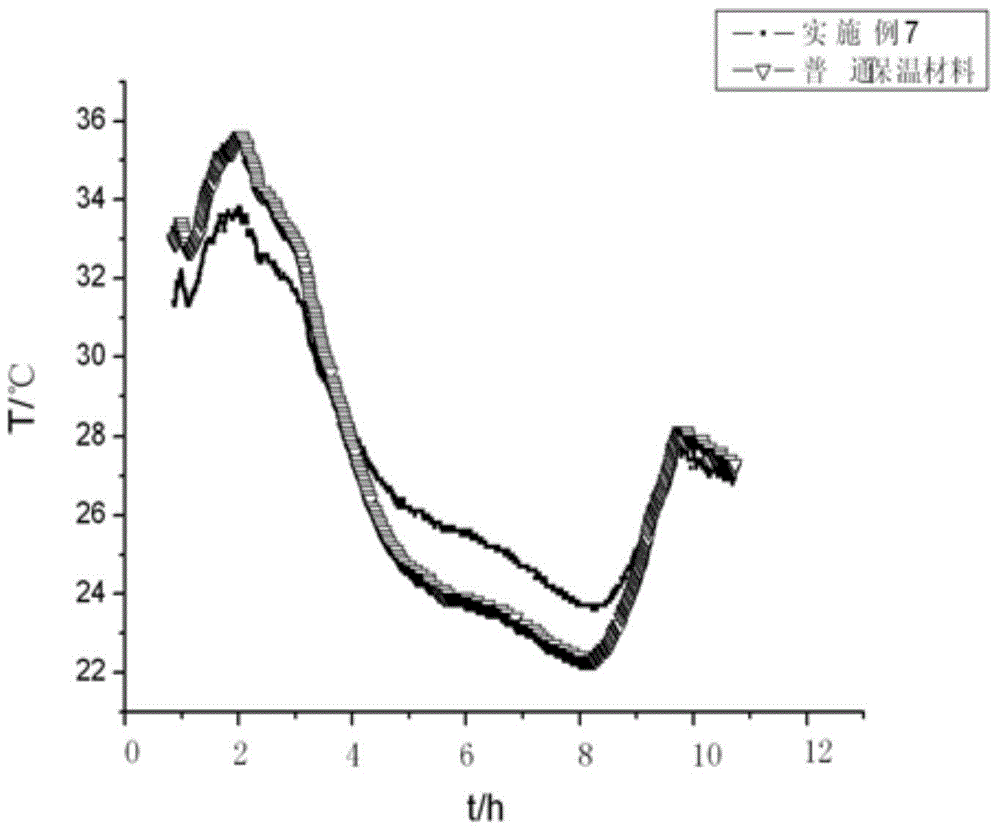

Embodiment 7

[0034] A shaped phase change material used for heat storage in ground heating is made by the following method:

[0035] (1) Anhydrous calcium chloride is mixed with water in the ratio of 111:108 by mass until no precipitation is obtained to obtain calcium chloride hexahydrate;

[0036] (2) take each raw material by the formula of embodiment 1;

[0037] (3) Add sodium sulfate decahydrate, sodium chloride, potassium chloride, strontium chloride and borax to calcium chloride hexahydrate, stir to dissolve, add water to obtain phase change mother liquor;

[0038] (4) be the ratio of 1:1 by the mass ratio of brucite fiberboard and phase-change mother liquor, make brucite fiberboard adsorption phase-change mother liquor;

[0039] (5) wrapping the article obtained in step (4) with a flexible plastic film;

[0040] (6) Wrap the article obtained in step (5) with aluminum foil to obtain a shaped phase change material for heat storage in floor heating.

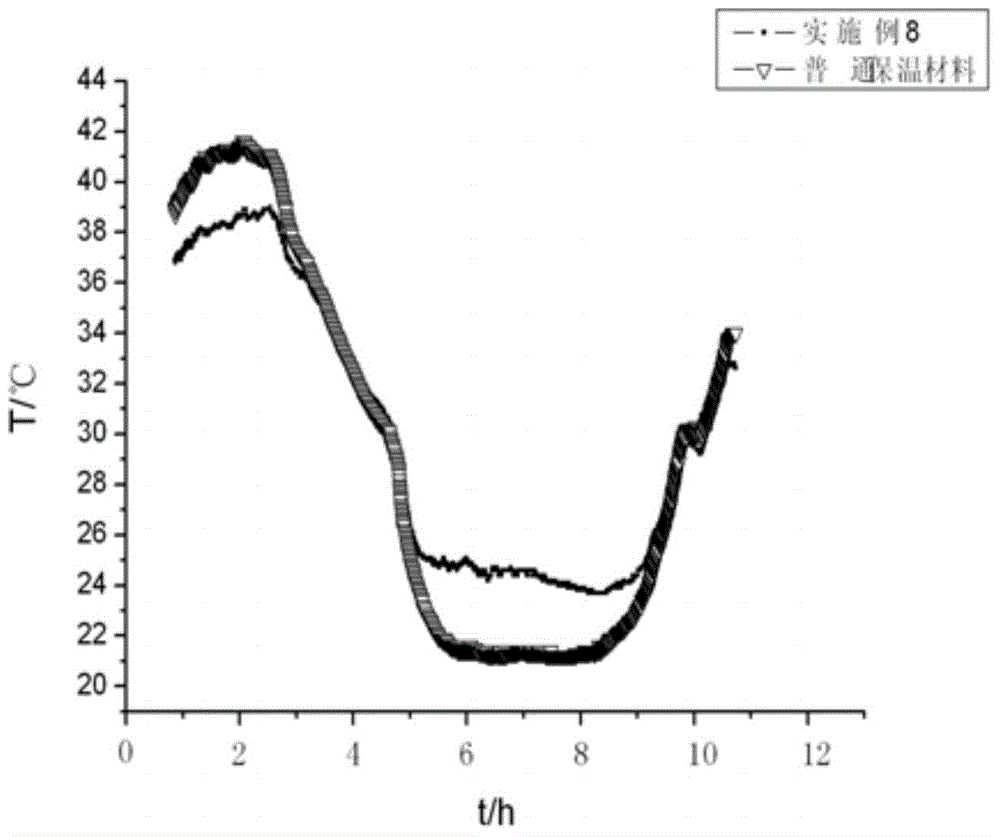

Embodiment 8

[0042] A shaped phase change material used for heat storage in ground heating is made by the following method:

[0043] (1) Anhydrous calcium chloride is mixed with water in the ratio of 111:108 by mass until no precipitation is obtained to obtain calcium chloride hexahydrate;

[0044] (2) take each raw material by the formula of embodiment 2;

[0045] (3) Add sodium sulfate decahydrate, sodium chloride, potassium chloride, strontium chloride, calcium sulfate and barium sulfate in calcium chloride hexahydrate, stir to dissolve, add water to obtain phase change mother liquor;

[0046] (4) by the mass ratio of sepiolite fiberboard and phase-change mother liquor is the ratio of 1:2, make sepiolite fiberboard adsorption phase-change mother liquor;

[0047] (5) wrapping the article obtained in step (4) with a flexible plastic film;

[0048] (6) Wrap the article obtained in step (5) with aluminum foil to obtain a shaped phase change material for heat storage in floor heating.

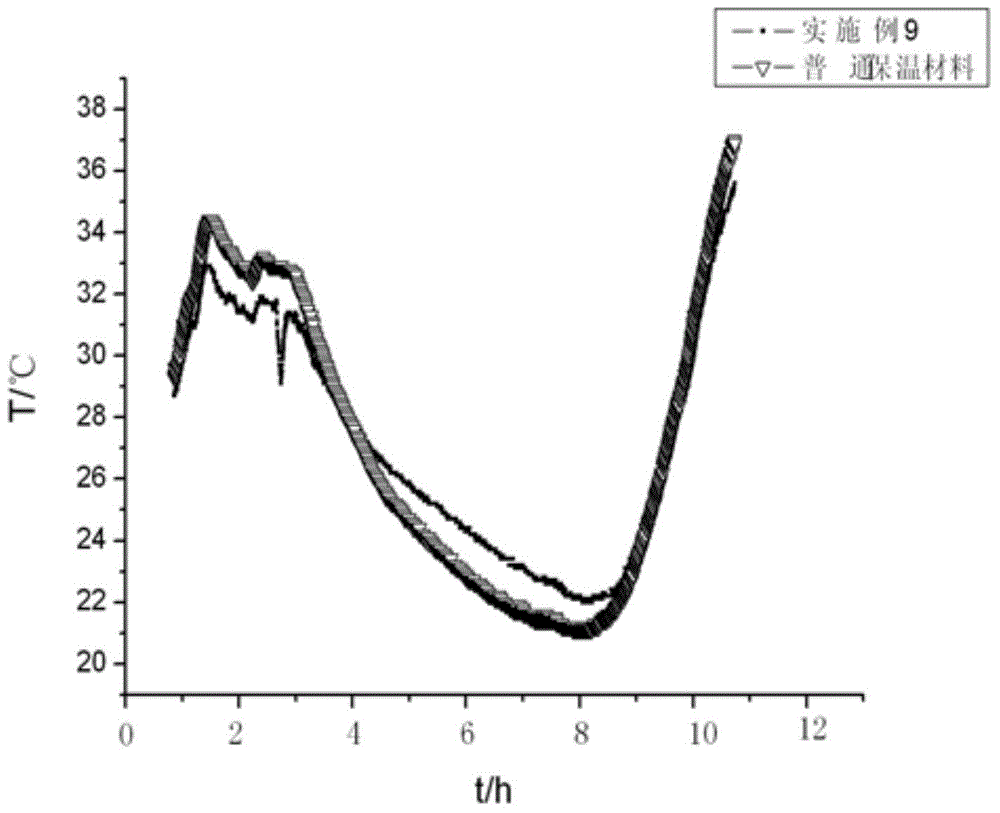

Embodiment 9

[0050] A shaped phase change material used for heat storage in ground heating is made by the following method:

[0051] (1) Anhydrous calcium chloride is mixed with water in the ratio of 111:108 by mass until no precipitation is obtained to obtain calcium chloride hexahydrate;

[0052] (2) take each raw material by the formula of embodiment 3;

[0053] (3) Add sodium sulfate decahydrate, sodium chloride, potassium chloride, strontium chloride, calcium sulfate and barium sulfate in calcium chloride hexahydrate, stir to dissolve, add water to obtain phase change mother liquor;

[0054] (4) by the mass ratio of mullite fiberboard and phase change mother liquor is the ratio of 2:1, mullite fiberboard is adsorbed phase change mother liquor;

[0055] (5) wrapping the article obtained in step (4) with a flexible plastic film;

[0056] (6) Wrap the article obtained in step (5) with aluminum foil to obtain a shaped phase change material for heat storage in floor heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com