Method for preparing graphene/lead compound composite material

A lead compound and composite material technology, applied in electrical components, battery electrodes, nanotechnology, etc., can solve the problem that lead active materials and carbon materials have less effective contact interface, can not give full play to the advantages of high conductivity and large capacitance of carbon, and are very uniform in mixing. Difficult to achieve and other problems, to achieve the effect of improving the effective contact area, good capacitance and battery performance, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

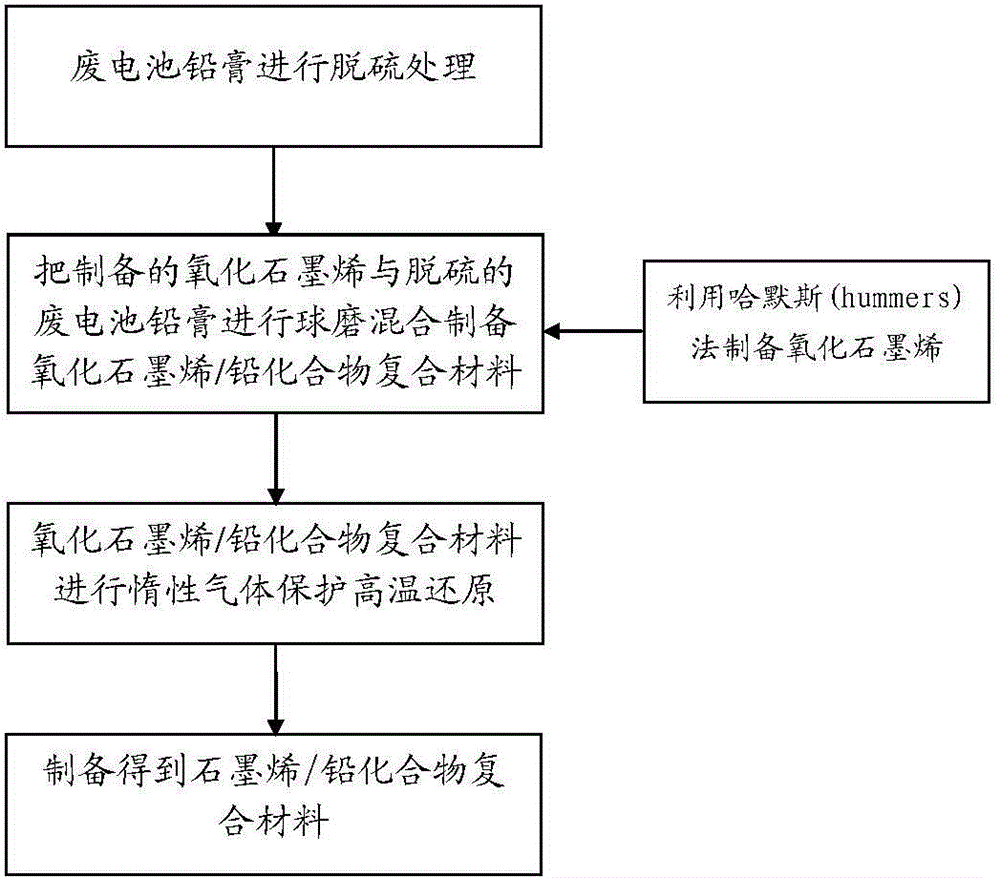

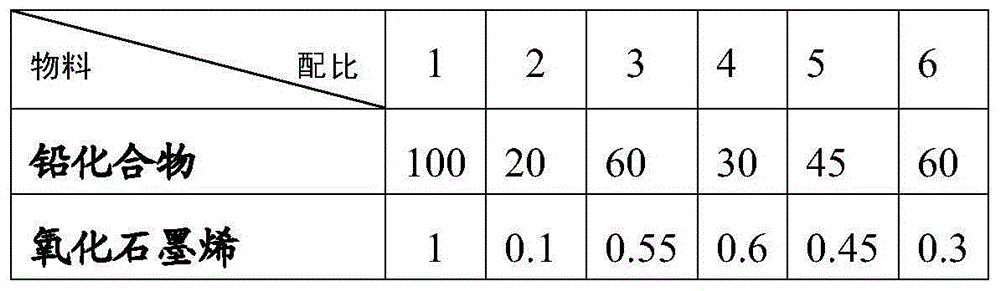

[0037] The preparation method shown in this embodiment mainly comprises the following steps (please refer to figure 1 ):

[0038] (1) Hammers (hummers) method to prepare graphene oxide

[0039] Concentrated H 2 SO 4 (69 ml) was added graphite flakes (3.0 g, 1 wt. equivalent) and NaNO 3 (1.5 g, 0.5 wt equiv), the resulting mixture was cooled to 0°C. Slowly add KMnO in batches 4 (9.0 g, 3 wt equiv), the reaction temperature was kept below 20°C. The reaction mixture was warmed to 35°C and stirred for 30 minutes, at which point water (138 mL) was added slowly, with a large exotherm to 98°C. External heating was introduced to maintain the reaction temperature at 98°C for 15 minutes, then the reaction mixture was cooled with a water bath for 10 minutes. Then add more water (420 ml) and 30% H2 o 2 (3 mL), exotherm again. After air cooling, 1.2 g of the obtained black solid mixture was purified, which was graphene oxide. Different weights of graphene oxide can be prepared ac...

Embodiment 2

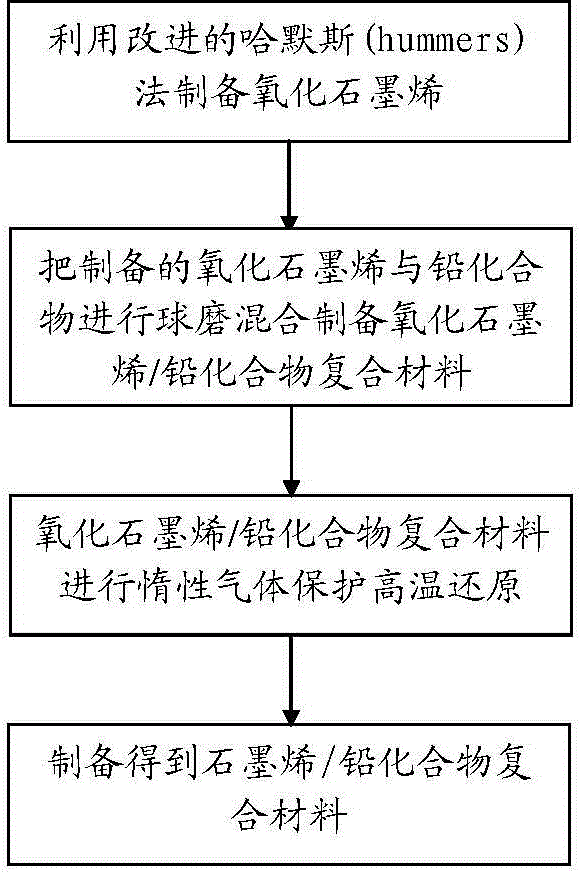

[0050] The preparation method shown in this embodiment mainly comprises the following steps (please refer to figure 2 ):

[0051] (1) Improved Hammers (hummers) method for preparing graphene oxide

[0052] With 325 mesh graphite as the initial raw material, 7.2mL of 98% concentrated sulfuric acid, 1.5g of potassium thiosulfate and 1.5g of phosphorus pentoxide were added to 0.9g of graphite powder. Then the mixture was stirred and reacted at 80° C. for 4.5 h, and then the reactant was diluted with about 500 mL of distilled water, filtered, and the filter cake was dried overnight in a 70° C. blast oven. Put the above-mentioned treated graphite powder into a 250mL beaker, slowly add 23mL of concentrated sulfuric acid and 0.5g of sodium nitrate under an ice-water bath, stir for five minutes, then slowly add 3g of potassium permanganate to it, and stir in an ice-water bath for 30 Minutes, and then slowly warmed to 35 ° C, maintaining the temperature and stirring the reaction for...

Embodiment 3

[0061] The preparation method shown in this embodiment mainly comprises the following steps:

[0062] Steps (1) and (3) in this embodiment are the same as steps (1) and (3) in Embodiment 1 or Embodiment 2 above. Step (2) in this embodiment is the same as step (2) in Embodiment 1.

[0063] The difference is step (4), namely:

[0064] (4) Preparation of graphene / lead compound composites by reduction with reducing agent and deionized water

[0065] Take a certain amount of graphene oxide / lead compound composite material and add it to an aqueous solution containing 2g of glucose as a reducing agent, add 2ml of ammonia water dropwise, stir at 90°C for 2h, filter with suction, wash until neutral, dry and grind to obtain light black graphene / lead compound composites. The reducing agent can be at least one of hydrazine hydrate, sodium borohydride, glucose, sodium citrate, ethylenediamine, ascorbic acid, hydroiodic acid, and L-cysteine as required. The feeding mass ratio of reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com