Method for preparing gain medium of polymer optical waveguide amplifier by copolymerizing rare-earth nanoparticles and monomers

An optical waveguide amplifier and nanoparticle technology, which is applied in the field of stable rare earth nanoparticles in polymers, stable film formation of rare earth nanoparticles and monomer copolymers, high-concentration doping, and can solve the problems of nanoparticle aggregation, precipitation, and doping Problems such as low concentration, inability to repeat measurement and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

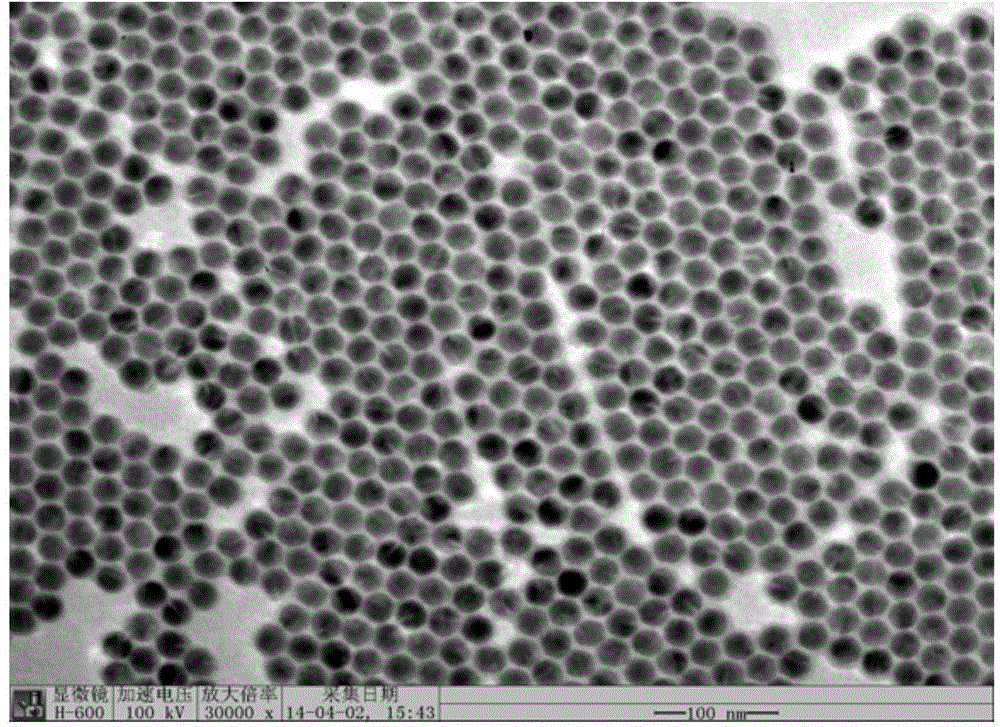

[0059] (1) Preparation of NaYF with surface-modified unsaturated double bonds by high-temperature pyrolysis 4 : Yb, Er nanoparticles: the matrix of rare earth nanoparticles is fluoride NaYF 4 , the sensitizer ion is Yb 3+ , the luminescence center ion is Er 3+ ; The oleic acid groups with polymerization active unsaturated double bonds are modified on the surface of nanoparticles. The specific synthesis steps are as follows: 1mmol rare earth chloride salt RECl 3 ·6H 2 O (rare earth chloride salt is a mixture of three chloride salts, wherein the molar percentage is 81% YCl 3 , 18% YbCl 3 , 1% ErCl 3 ), 15mL of octadecene, and 6mL of oleic acid were placed in a 100mL three-necked flask, and under the protection of argon, the temperature of the system was raised to 160°C, reacted for 30min, and then naturally cooled to room temperature. Then, 10 mL of anhydrous methanol mixed solution dissolved with 4 mmol of ammonium fluoride and 2.5 mmol of sodium hydroxide was slowly dro...

Embodiment 2

[0063](1) Preparation of surface-modified unsaturated double bond core-shell NaYF by solvothermal method 4 / NaYbF 4 : Er nanoparticles. Through heterogeneous core induction, a core-shell NaYF with surface-modified unsaturated double bonds was synthesized 4 / NaYbF 4 : Er nanoparticles; wherein the sensitizer ion Yb in the shell 3+ The doping amount is equivalent to 100%, and the luminescent center ion is Er 3+ , the doping concentration is 2%. In the environment of oleic acid, nanoparticles with surface-modified unsaturated double bonds were synthesized by a solvothermal method. Measure 20mL oleic acid, 10mL ethanol and 2mL deionized water and stir to mix. Weigh 0.6g of NaOH solid into the mixed solution, stir until fully dissolved, and obtain a clear solution A. Weigh 0.5mmol of YCl 3 ·6H 2 O solid, dissolved in 4 mL deionized water. This solution was added dropwise into mixed solution A, and stirred vigorously for half an hour to obtain solution B. Weigh 2mmolKF·2H...

Embodiment 3

[0067] (1) Utilize the precipitation method to prepare Y without polymerization active groups on the surface 2 o 3 : Er nanoparticles, the matrix of rare earth nanoparticles is oxide Y 2 o 3 , the sensitizer ion is not doped, that is, the doping amount of the sensitizer ion is 0%, and the luminescence center ion is Er 3+ , the concentration is 1%. The specific synthesis steps are as follows: 1mmol rare earth chloride salt RECl 3 ·6H 2 O (rare earth chloride salt is a mixture of two chloride salts, of which 99% YCl 3 , 1% ErCl 3 ) was dissolved in 20 mL of deionized water to form a transparent and clear solution, and under stirring conditions, 5 mL of NaOH solution with a mass fraction of 10% was slowly added dropwise to form a flocculent precipitate. Transfer the solution and precipitate to a 30mL polyethylene-lined reaction kettle, and after hydrothermal annealing at 200°C for 12 hours, cool to room temperature and centrifuge to obtain Y 2 o 3 : Er nanoparticles. F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com