Monodisperse magnetic nanoring as well as preparation method and application of monodisperse magnetic nanoring

A magnetic nano ring, monodisperse technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high energy consumption and large pollution, and achieve low energy consumption and low preparation cost , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

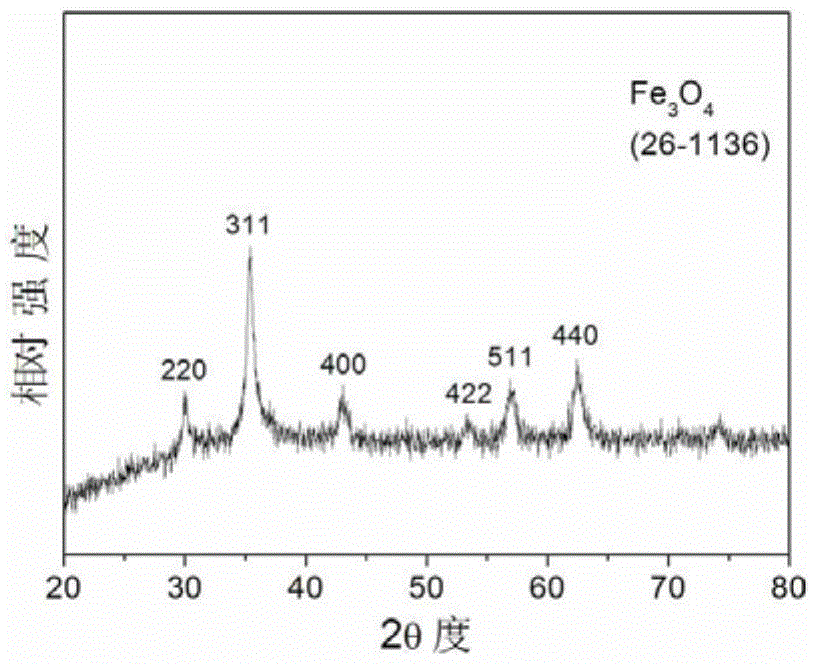

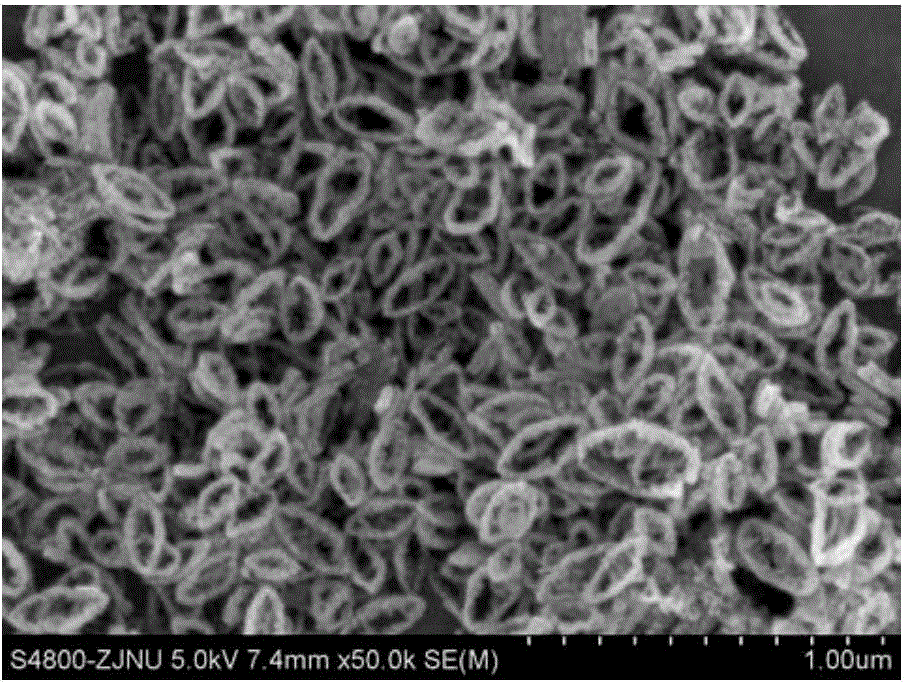

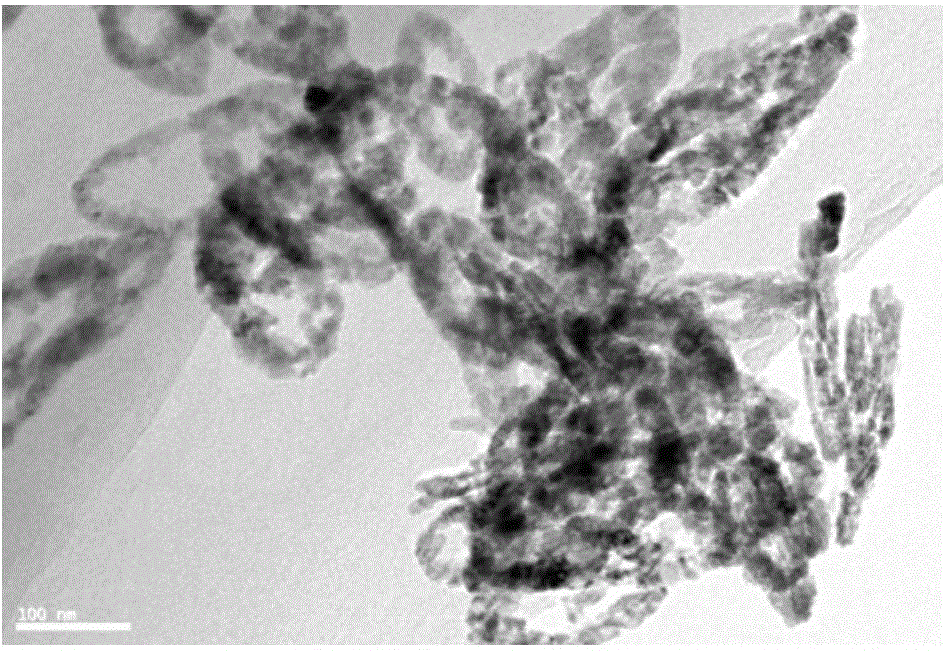

[0034] FeOOH nanosheets (44.5 mg), PVP (0.05 g), water (30 ml), glucose (99 mg) (the ratio of FeOOH nanosheets to glucose is 1:1) were first added to the microwave reaction vessel and stirred 15 minutes; then transferred to a microwave reactor and reacted at 180° C. for 1 hour, cooled, washed with water and ethanol by centrifugation, and finally dried to obtain the desired monodisperse magnetic nanorings. The phase of the obtained product, the morphology, structure and selected area electron diffraction pattern observed under the scanning electron microscope and transmission electron microscope are as follows Figure 1-4 As shown, it can be seen that the product is elliptical Fe 3 o 4 The polycrystalline nano ring has a long axis of 231-285nm, with an average length of 259nm; the ratio of the long axis to the short axis is 1.94-2.53, with an average of 2.15; the ratio of the inner and outer diameters of the ring is 0.71-0.80, with an average of 0.77. The particles are agglom...

Embodiment 2

[0036] The steps are the same as in Example 1, but the reaction temperature is 120°C. The morphology of the obtained product observed under the scanning electron microscope is as follows: Figure 5 As shown, it can be seen that the product is elliptical Fe 3 o 4 The polycrystalline nano ring has a long axis length of 146-227nm, with an average length of 175nm; the ratio of the long axis to the short axis is 1.86-2.51, with an average of 2.17; the ratio of the inner and outer diameters of the ring is 0.62-0.74, with an average of 0.66. The static magnetic performance test results are as follows: Figure 25 As shown, the saturation magnetization is 8.7emu g -1 , The coercivity is 31.4Oe.

Embodiment 3

[0038] The steps are the same as in Example 1, but the reaction temperature is 220° C., and the reaction time is 5 minutes. The morphology of the obtained product observed under the scanning electron microscope is as follows: Figure 6 As shown, it can be seen that the product is elliptical Fe3 o 4 The polycrystalline nano ring has a long axis length of 190-289nm, with an average length of 235nm; the ratio of the long axis to the short axis is 1.71-2.65, with an average of 2.06; the ratio of the inner and outer diameters of the ring is 0.65-0.83, with an average of 0.75. The static magnetic performance test results are as follows: Figure 25 As shown, the saturation magnetization is 47.3emu·g -1 , The coercivity is 16.7Oe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com