Novel fluororubber vulcanizer and preparation method thereof

A vulcanizing agent and fluororubber technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxy compounds, etc., to achieve the effects of high strength, mild reaction conditions and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A novel fluorine rubber vulcanizing agent, the structural formula of the vulcanizing agent is as follows:

[0026]

[0027] Above-mentioned structural formula belongs to general formula I, wherein R 1 =C 6 h 12 N H 2 .

[0028] The raw material for the preparation of the above vulcanizing agent is: p-(1-nitrohexyl)phenol. The specific preparation method is as follows: add a certain amount of p-(1-nitrohexyl)phenol in the reaction kettle, add a metal catalyst such as iron powder, then add an appropriate amount of hydrochloric acid, and carry out hydrogenation reduction reaction with hydrogen gas, and control the reaction temperature. 30-40°C, the pressure in the reactor is controlled between 0.4-0.6MPa, react overnight to fully reduce the nitro group to amino group, and the above product can be obtained with a yield of 92%. Number is 1 # .

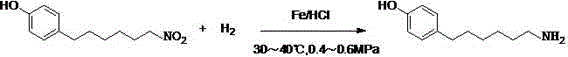

[0029] The above reaction equation is as follows:

[0030]

Embodiment 2

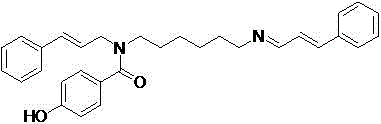

[0032] A novel fluorine rubber vulcanizing agent, the structural formula of the vulcanizing agent is as follows:

[0033]

[0034] Above-mentioned structural formula belongs to general formula I, wherein R 1 =C 6 h 15 ON 2 .

[0035] The raw materials for the above vulcanizing agent are: p-hydroxybenzoic acid and 1,6-hexamethylenediamine. The specific preparation method is as follows: add an appropriate amount of solvent (such as toluene, etc.) The reaction was carried out under reflux for 4.5 hours. During the reflux process, a water separator was used to divide the water. After the reaction, the solvent was removed in a vacuum. Number is 2 # .

[0036] The above reaction equation is as follows:

[0037]

Embodiment 3

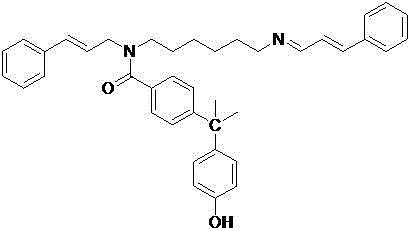

[0039] A novel fluorine rubber vulcanizing agent, the structural formula of the vulcanizing agent is as follows:

[0040]

[0041] Above-mentioned structural formula belongs to general formula I, wherein R 1 =C 25 h 29 ON 2 .

[0042] The raw materials for the preparation of the vulcanizing agent are: p-hydroxybenzoic acid and N,N-dicinnamyl-1,6-hexanediamine. The specific preparation method is as follows: add an appropriate amount of solvent (such as toluene, etc.) -1,6-Hexamethylenediamine, reflux reaction for 5 hours, during the reflux process, use a water separator to separate the water. After the reaction, remove the solvent in a vacuum. After the product is cooled, it can be crushed. The yield of the above product is 92%. Number is 3 # .

[0043] The above reaction equation is as follows:

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com