Composite material pipeline

A composite material and pipeline technology, used in pipeline protection, pipeline anti-corrosion/rust protection, pipes, etc., can solve the problems of increasing the difficulty of steel pipe handling and installation, increasing the weight and volume of steel pipes, and achieve excellent corrosion resistance. , Improve corrosion resistance, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

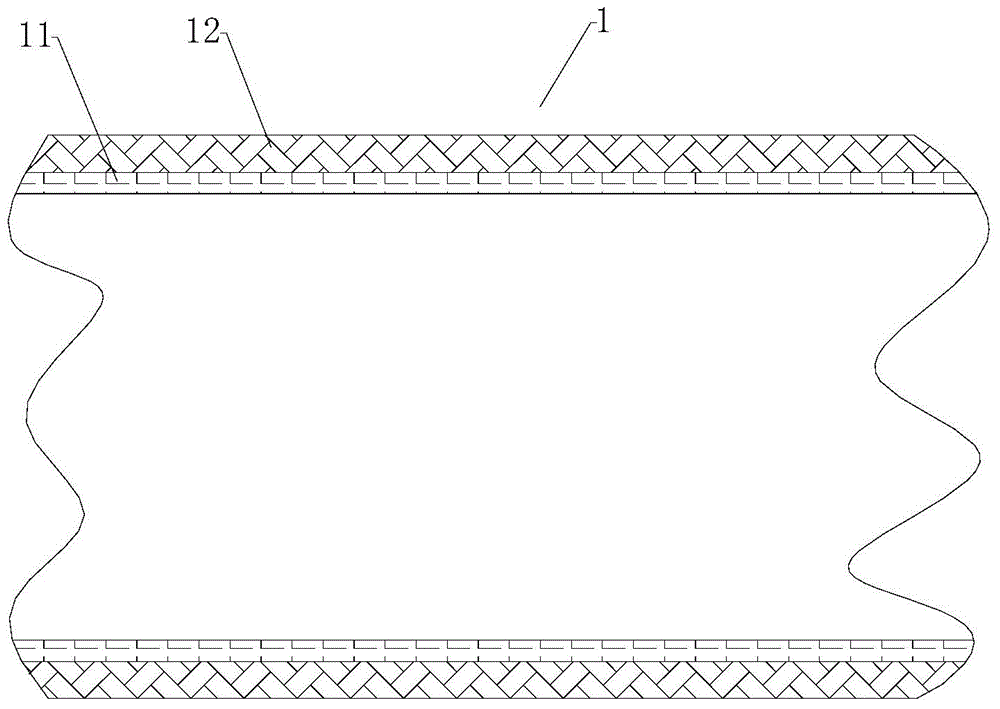

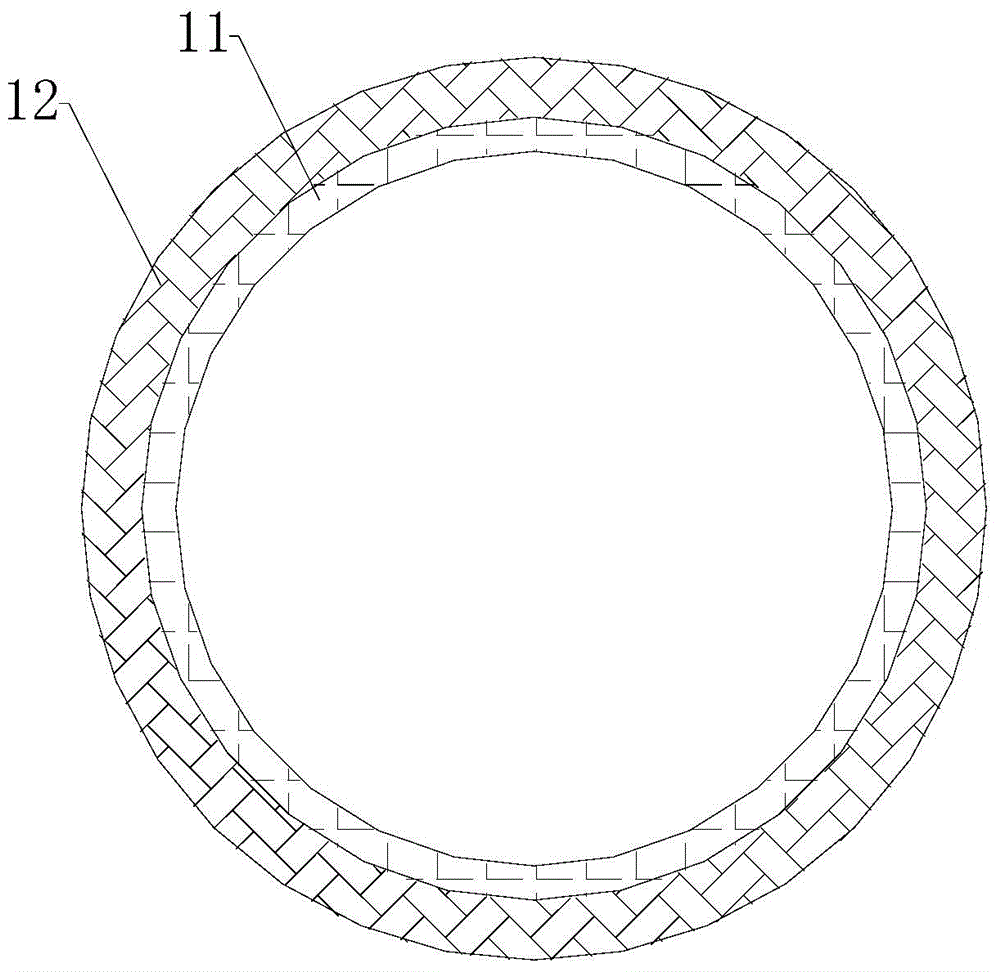

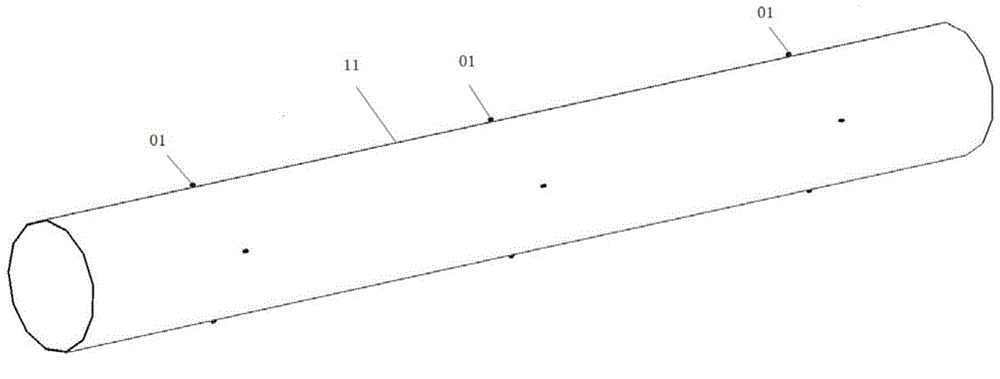

[0053] Such as figure 1 and 2 As shown, the composite material pipeline includes a pipeline body 1 . The pipeline main body 1 includes a conductive liner 11, and the conductive liner 11 is provided with a lumen. The conductive liner 11 is made of titanium alloy or thermoplastic resin mixed with conductive material, and the thermoplastic resin is polyvinylidene chloride resin, high-density polyethylene resin, polypropylene resin, polycarbonate resin, acrylonitrile-butadiene-benzene One or any of ethylene copolymer resin, polyvinyl chloride resin, polymethyl methacrylate resin, polytetrafluoroethylene resin and nylon-11 (ie polyω-amino undecanoyl) resin, the conductive material can be It is conductive graphite, carbon fiber or carbon powder. In this implementation, the conductive inner container 11 is preferably made of titanium alloy.

[0054] The outer surface of the conductive liner 11 is covered with a first fiber reinforced resin layer 12 . The first fiber-reinforced r...

Embodiment 2

[0057] Such as Figure 4 and 5 As shown, the composite material pipeline includes a pipeline body 1 . The pipe body 1 includes a conductive liner 11 . The conductive liner 11 is made of titanium alloy.

[0058] The outer surface of the conductive liner 11 is covered with a thermoplastic resin sealing layer 13 . The thermoplastic resin sealing layer 13 is made of thermoplastic resin. The thermoplastic resin is polyvinylidene chloride resin, high-density polyethylene resin, polypropylene resin, polycarbonate resin, acrylonitrile-butadiene-styrene copolymer resin, polyvinyl chloride resin, polymethyl methacrylate resin, One or more of polytetrafluoroethylene resin and nylon-11 (ie, polyomega-aminoundecanoyl) resin.

[0059] The outer surface of the thermoplastic resin sealing layer 13 is covered with the first fiber-reinforced resin layer 12 . The first fiber-reinforced resin layer 12 includes first fibers and a first resin. The first fiber-reinforced resin layer 12 is for...

Embodiment 3

[0061] One of the differences between this embodiment and Embodiment 2 is: the conductive liner 11 is made of thermoplastic resin mixed with conductive material. The thermoplastic resin is polyvinylidene chloride resin, high-density polyethylene resin, polypropylene resin, polycarbonate resin, acrylonitrile-butadiene-styrene copolymer resin, polyvinyl chloride resin, polymethyl methacrylate resin, One or more of polytetrafluoroethylene resin and nylon-11 (ie, polyomega-aminoundecanoyl) resin. The conductive material is conductive graphite, carbon fiber or carbon powder.

[0062] The second difference between this embodiment and Embodiment 2 is that the thermoplastic resin sealing layer 13 is replaced by an inert metal layer. The thin layer of inert metal is formed by winding the outer surface of the conductive liner 11 sequentially with an inert metal film. The inert metal film is a copper film. Each layer of copper film is lapped during winding, and sealing resin or glue i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com