Preparation method of polymer micro-capsules inspired by polyphenols chemistry

A polyphenol chemistry and polymer technology, which is applied in the preparation of microspheres and microcapsule preparations, can solve the problems of preparing microcapsules by polyphenol chemistry, and achieve the effects of simple and easy preparation process, cheap preparation materials and mild preparation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1, preparation concentration is 0.33M calcium chloride solution, adds polystyrene sodium sulfonate (PSS) wherein, is made into the solution A that PSS concentration is 3mg / mL; Preparation and the sodium carbonate of the same molar concentration of calcium chloride solution Solution; each take 10mL of solution A and sodium carbonate solution, quickly pour the sodium carbonate solution into solution A at a speed of 800r / min, react for 30s, turn off the stirring and let it stand for 10min, then centrifuge at a speed of 3000r / min , washed with deionized water after removing the supernatant, and repeated centrifugation-water washing three times to obtain calcium carbonate microspheres doped with polystyrene sodium sulfonate (PSS-doped CaCO 3 Microspheres);

[0021] Step 2, prepare a Tris-HCl buffer solution with a concentration of 0.05M, and adjust the pH of the buffer solution to 8.0;

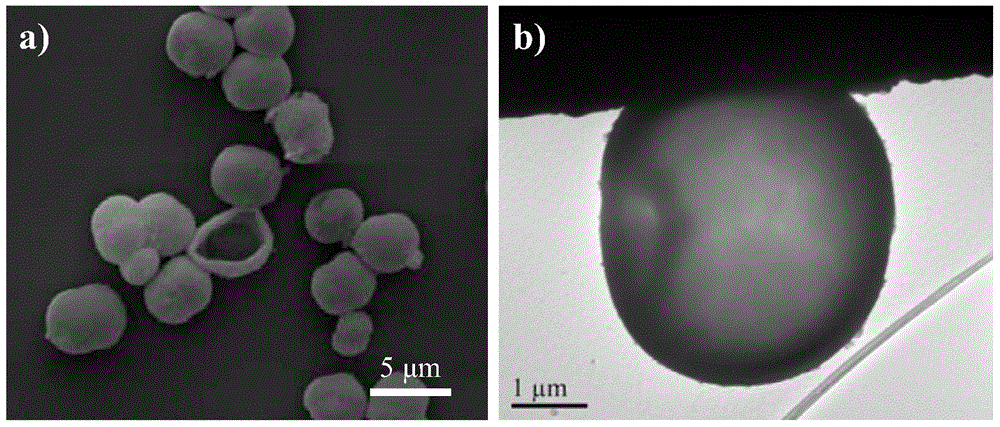

[0022] Step 3: Dissolve tannic acid (TA) in the Tris-HCl buffer solution prepared ...

Embodiment 2

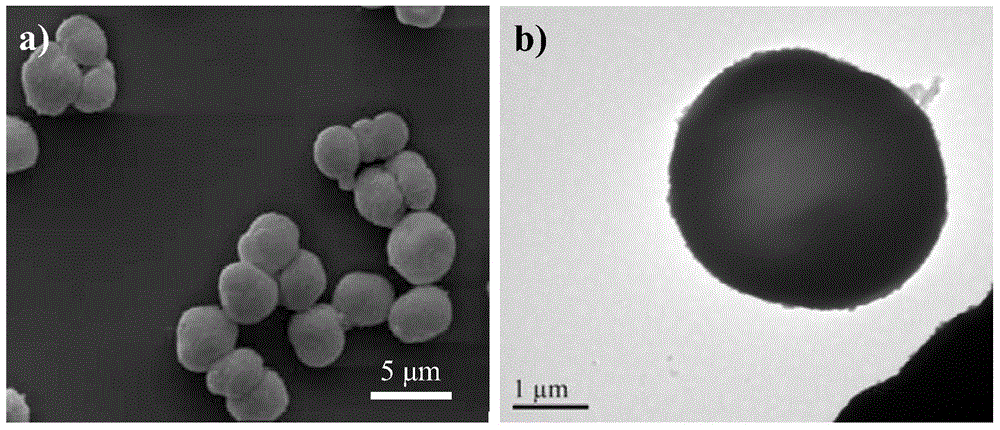

[0026] The steps of this example are basically the same as those of Example 1, except that the concentration of TA in solution B prepared in step 3 is changed from 0.5 mg / mL to 1.0 mg / mL, and the particle size of the final prepared TA / PEI microcapsules The microcapsule is 4-5 microns, the thickness of the capsule wall is 392±31 nanometers, and the microcapsule remains spherical after freeze-drying. figure 2 In a) is the SEM photo of the TA / PEI microcapsule prepared in Example 2, and b) is the TEM photo of the TA / PEI microcapsule prepared in Example 2.

Embodiment 3

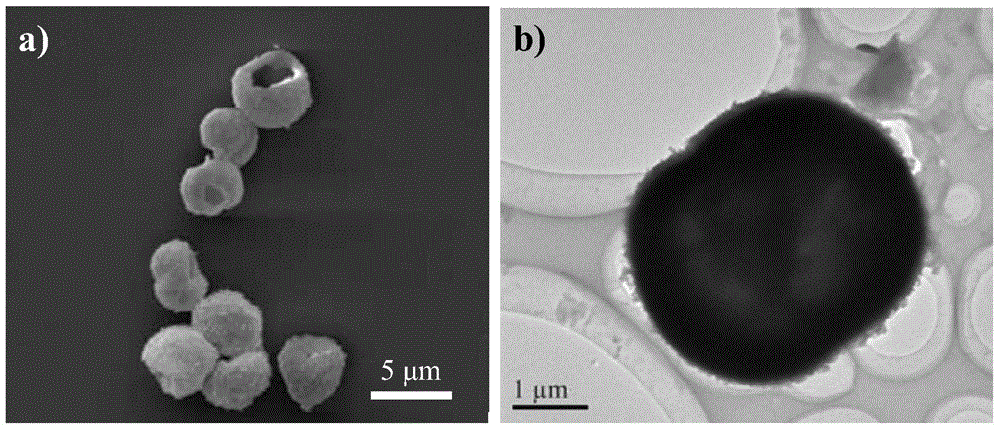

[0028]The steps of this example are basically the same as those of Example 1, except that the concentration of TA in solution B prepared in step 3 is changed from 0.5 mg / mL to 2.0 mg / mL, and the final prepared TA / PEI microcapsules have the following characteristics , the particle size is 4-5 microns, the thickness of the capsule wall is 486±46 nanometers, and the microcapsule remains spherical after freeze-drying. image 3 In a) is the SEM photo of the TA / PEI microcapsule prepared in Example 3, and b) is the TEM photo of the TA / PEI microcapsule prepared in Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com