Preparation method for CZTS (Se) nano-crystalline thin film

A nanocrystalline and thin film technology, applied in the field of solar photovoltaic materials, can solve the problems of difficulty in preparing CZTSSe nanocrystalline thin films, reducing photoelectric conversion efficiency of solar cell devices, poor controllability, etc., and achieving high photoelectric conversion efficiency, strong controllability, Enhanced solubility and diffusion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Preparation of binary nanocrystalline particles

[0048] a. 3mmol SnCl 2 2H 2 O and 30mmol of sodium citrate were dissolved in 200ml of ethylene glycol to obtain solution A; 3mmol of Na 2 S·9H 2 O was dissolved in 100ml of ethylene glycol to obtain solution B; then, under stirring conditions, solution A and solution B were mixed together, and the resulting brown product was centrifuged to obtain a solid, which was washed 3 times with absolute ethanol and dried to obtain SnS binary nanocrystalline particles;

[0049] b. Add 5mmol Zn(CH 3 COO) 2 2H 2 The tartaric acid of O and 30mmol was dissolved in 20ml deionized water to obtain solution C; 6mmol Na 2 S·9H 2 O was dissolved in 20ml of deionized water to obtain solution D; then, under stirring conditions, solution C and solution D were mixed together, kept at 160°C for 1 hour, and the white precipitate was centrifuged, and the precipitate was washed twice with deionized water, and then Wash twice with absolu...

Embodiment 2

[0064] (1) Preparation of binary nanocrystalline particles

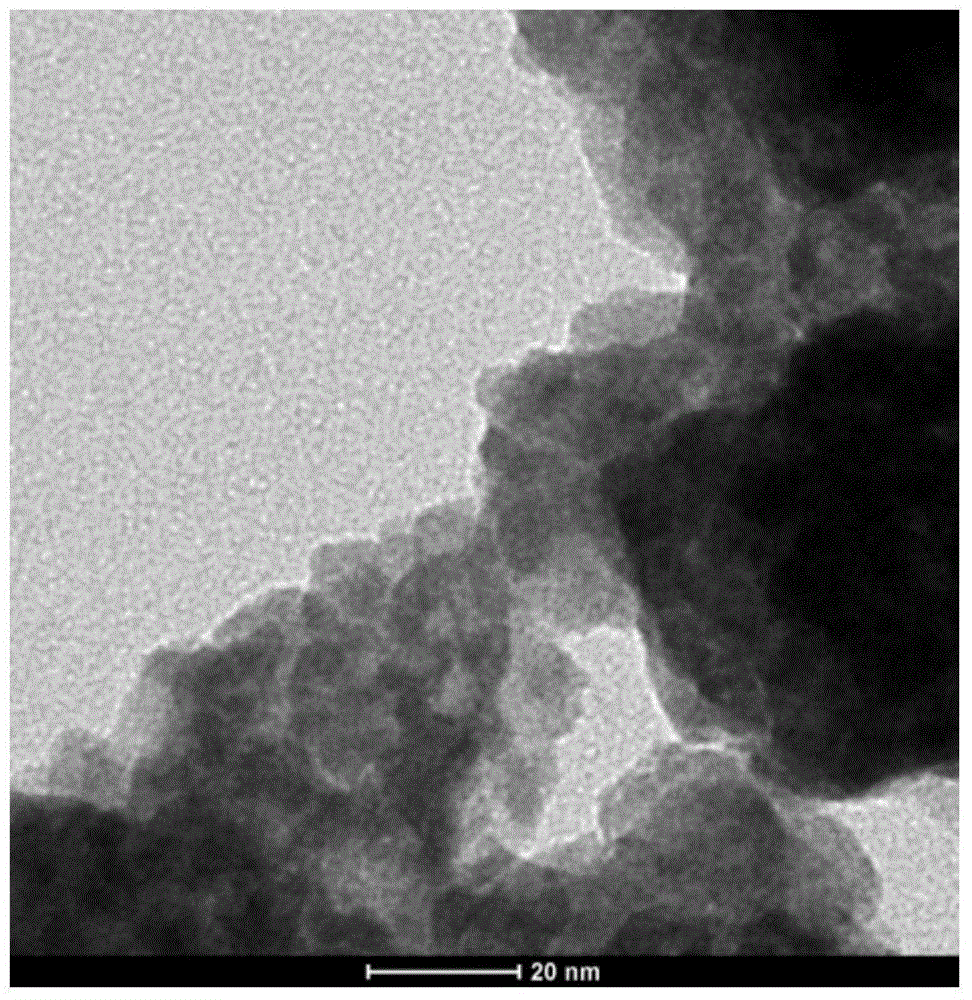

[0065] a. Add 6mmol SnCl 2 2H 2 O and 40mmol of acetic acid were dissolved in 200ml of triethanolamine to obtain solution A; 6mmol of Na 2 S·9H 2 O was dissolved in 100ml triethanolamine to obtain solution B; then, under stirring conditions, solution A and solution B were mixed together, and the resulting brown product was centrifuged to obtain a solid, which was washed 3 times with absolute ethanol and dried to obtain SnS Binary nanocrystalline particles, tested by TEM, have a particle size of about 20nm.

[0066] b. Add 10mmol Zn(CH 3 COO) 2 2H 2 O and 50mmol of acetic acid were dissolved in 40ml of triethanolamine to obtain solution C; 4mmol of Na 2 S·9H 2 O was dissolved in 20ml of triethanolamine to obtain solution D; then, under stirring conditions, solutions C and D were mixed together, kept at 160°C for 1 hour, and the white precipitate was centrifuged, washed twice with deionized water, and then wash...

Embodiment 3

[0077] (1) Preparation of binary nanocrystalline particles

[0078] a. Dissolve 4mmol of tin acetate and 30mmol of acetic acid in 200ml of methanol to obtain solution A; dissolve 4mmol of S powder in 100ml of methanol to obtain solution B; then mix solution A and solution B together under stirring conditions, The resulting product was centrifuged to obtain a solid, washed 3 times with absolute ethanol, and dried to obtain SnS binary nanocrystalline particles;

[0079] b. 5mmol of zinc chloride and 50mmol of citric acid were dissolved in 50ml of deionized water to obtain solution C; 3mmol of Na 2 S·9H 2 O was dissolved in 30ml of deionized water to obtain solution D; then, under stirring conditions, solution C and solution D were mixed together, kept at 100°C for 20 hours, the precipitate was centrifuged, and the precipitate was washed twice with deionized water, and then washed with Washed twice with absolute ethanol and dried to obtain ZnS binary nanocrystalline particles. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com