Large-area cadmium sulfide film preparing method

A thin-film preparation and cadmium sulfide technology, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve the problems of environmental pollution of ammonia water, waste of resources, etc., achieve low reaction temperature, avoid corrosion, and improve performance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

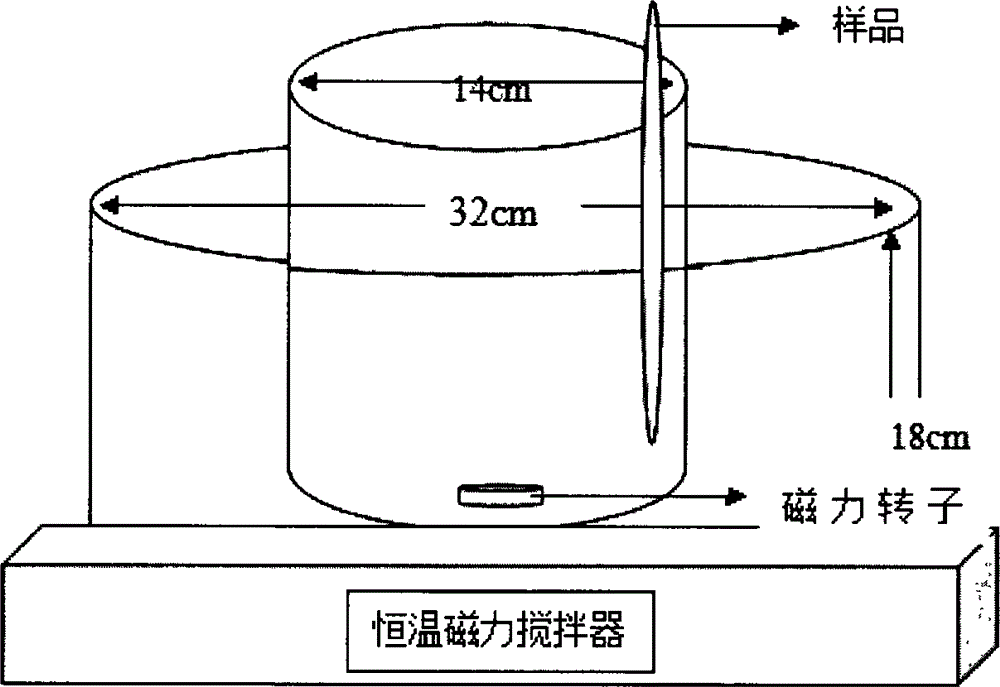

[0047] A large-area cadmium sulfide thin film is prepared by using a chemical water bath method based on a copper indium gallium selenide substrate. The preparation steps are as follows:

[0048] Preparation of CIGS substrate: Firstly, the CIGS absorbing layer prepared on the glass substrate must be obtained.

[0049] 1) Cleaning of soda lemon glass

[0050] ① Soak a 10cm×10cm soda glass in heavy potassium hydroxide solution (a solution made of 300 grams of potassium hydroxide and 3 liters of deionized water) for 2 hours; ② Put the rinsed soda glass in a concentration of 99.5 % acetone solution, put it into an ultrasonic cleaning machine for cleaning with an ultrasonic frequency of 50kHz and a time of 30min, which can be properly heated to 40°C; ③ Take the soda glass out of the acetone solution and rinse it with deionized water; ④ Clean the washed Soda-lemon glass substrates were cleaned with alcohol and dried with nitrogen.

[0051] 2) Preparation of molybdenum back contact...

Embodiment 2

[0064] A large-area cadmium sulfide thin film is prepared by using a chemical water bath method based on a copper indium gallium selenide substrate. The preparation steps are as follows:

[0065] Preparation of CIGS substrate: Firstly, the CIGS absorbing layer prepared on the glass substrate must be obtained.

[0066] 1) Cleaning of soda lemon glass

[0067] ① Soak a 10cm×10cm soda glass in heavy potassium hydroxide solution (a solution made of 300 grams of potassium hydroxide and 3 liters of deionized water) for 2 hours; ② Put the rinsed soda glass in a concentration of 99.5 % acetone solution, put it into an ultrasonic cleaning machine for cleaning with an ultrasonic frequency of 50kHz and a time of 30min, which can be properly heated to 40°C; ③ Take the soda glass out of the acetone solution and rinse it with deionized water; ④ Clean the washed Soda-lemon glass substrates were cleaned with alcohol and dried with nitrogen.

[0068] 2) Preparation of molybdenum back contact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com