Preparation method for tin-based/graphene composite anode material of lithium ion battery

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficulty in batch preparation of composite negative electrode materials, and the inability to achieve single-sided electrodeposition of current collectors, and achieves benefits that are beneficial to batch operations and reduce energy consumption. Small equivalent series resistance, tight bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

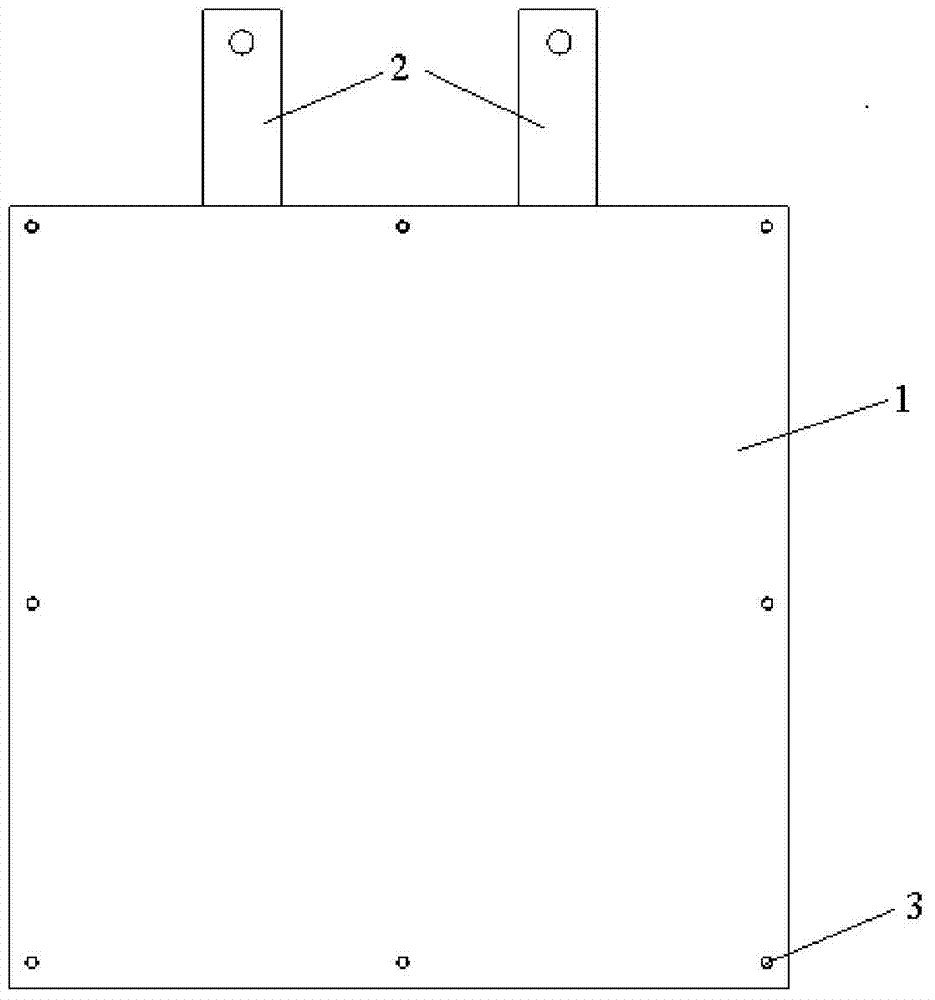

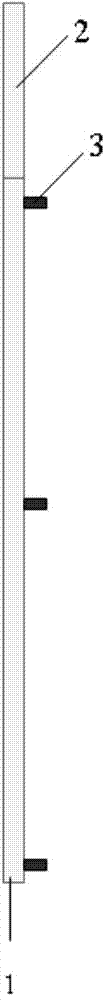

[0038] Specific implementation plan one: combine Figure 1-Figure 6 Specifically illustrate this embodiment, the preparation method of the tin-based / graphene lithium-ion battery composite negative electrode material in this embodiment, the tin-based / graphene lithium-ion battery composite negative electrode material is a tin / graphene lithium-ion battery composite negative electrode material, The preparation method is to carry out according to the following steps:

[0039] 1. The preparation of the plating solution: first add the complexing agent into the water, then add the tin salt, the reducing agent, the grain refiner, the dispersant and the graphite oxide aqueous solution in turn, stir evenly to obtain the mixed solution, and then add the mixed solution at a temperature of 25 Ultrasonic in an ultrasonic generator at ℃~30℃ for 1h~3h to obtain the plating solution;

[0040] The concentration of tin salt in the described plating solution is 20g / L~80g / L; The concentration of c...

specific Embodiment approach 2

[0050] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the tin salt described in step one is one of stannous sulfate, stannous chloride, stannous methanesulfonate and stannous oxalate or Two mixtures; the complexing agent described in step one is citric acid, potassium citrate, trisodium citrate, disodium edetate, sulfuric acid, methanesulfonic acid, tartaric acid, thiourea and malic acid One or a mixture of several of them; the reducing agent described in step one is ascorbic acid, sodium ascorbate, hydroquinone, glucose, citric acid, formic acid, sodium borohydride, tannic acid, ethylene glycol and glycerin One or two mixtures; the dispersant described in step one is polyacrylic acid, sodium polyacrylate, sodium lignosulfonate, sodium polynaphthaldehyde sulfonate, sodium dodecylsulfonate, polyether nonionic Type surfactant OP-10 or octylphenol polyoxyethylene ether TX-10; the grain refiner described in step 1 is 3,4-dioxymethyl...

specific Embodiment approach 3

[0051] Specific implementation mode three: combination Figure 7-Figure 8 Describe this embodiment in detail. The difference between this embodiment and one of the specific embodiments 1 or 2 is that in step 2, installing the current collector metal foil with the positioning hole into the cathode device is carried out in the following steps: The current collector metal foil of the positioning hole is set on the cylindrical positioning column 3 of the cathode conductive plate 1, and the fixing cap 6 is covered on the cylindrical positioning column 3, and then the upper frame 7 is inserted from the side of the tab 2, and then Insert the two side frames 8 and the bottom frame 9 respectively from the other three sides, cover the cathode conductive plate 1, the current collector metal foil and the fixing cap 6, and finally put the four corner frames 10 on the upper frame 7, two On the four corners surrounded by the side frame 8 and the bottom frame 9 . Others are the same as in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com