Aqueous zinc ion single liquid flow battery

A technology of zinc ion and single battery, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor stability of negative electrode materials, low cycle life and limited development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

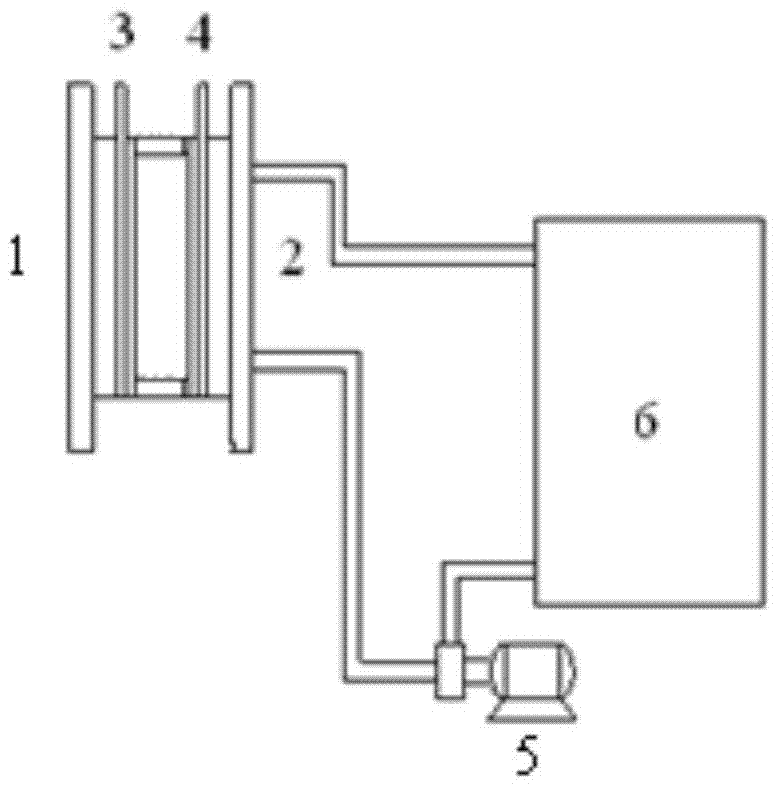

Image

Examples

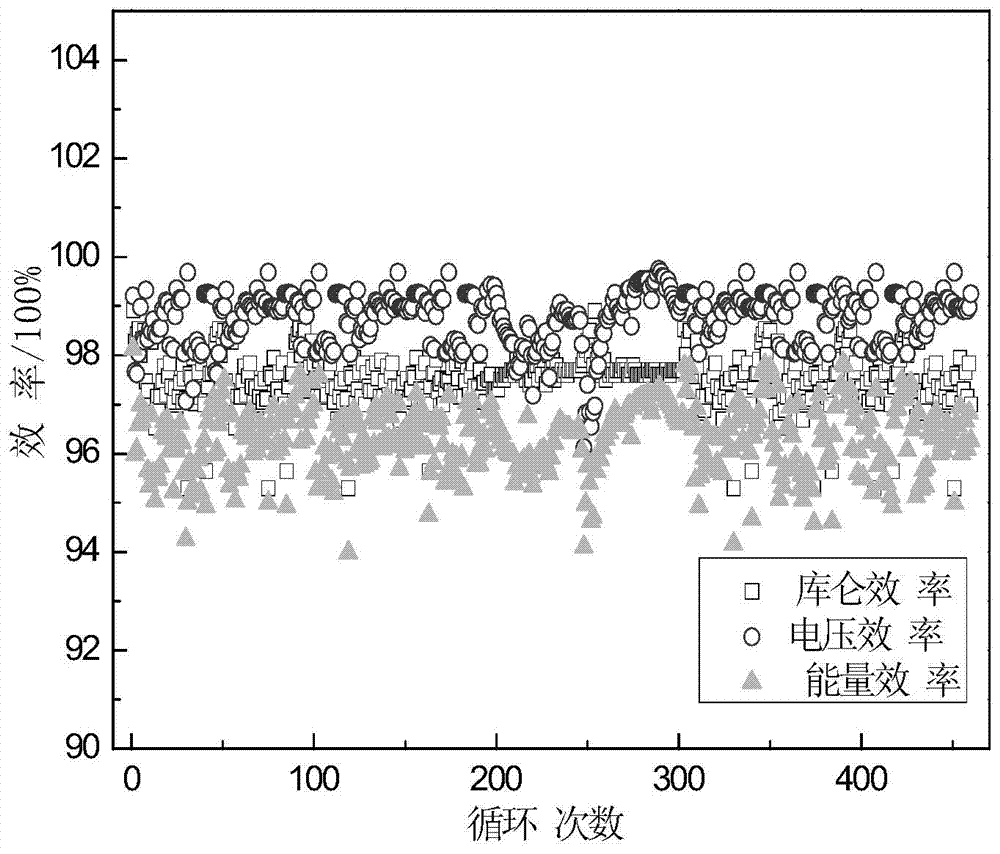

Embodiment 1

[0023] Preparation of positive electrode materials: (taking Mn oxide as an example)

[0024] Prepare 1L of 0.05mol / L MnSO 4 , 0.05mol / L LiNO 3 and 0.05mol / L K 2 S 2 o 2 Mix the solution, add 5 mL of 98% (w) concentrated H 2 S0 4 , A colorless and clear mixed solution was obtained after thorough stirring with a glass rod. The resulting colorless solution was reacted at a constant temperature in a water bath at 40° C. for 36 h. After the reaction was completed, the black precipitate was collected by suction filtration, washed repeatedly with deionized water until the solution was neutral, and dried under vacuum in an oven at 100°C for 12 hours to obtain the positive electrode material.

[0025] Preparation of positive electrode:

[0026] The prepared cathode material was mixed with acetylene black and PTFE (5% (w)) at a mass ratio of 75:15:10, and thoroughly ground with an agate mortar. Add an appropriate amount of ethanol, scrape evenly on 3x3cm with a blade 2 On the ...

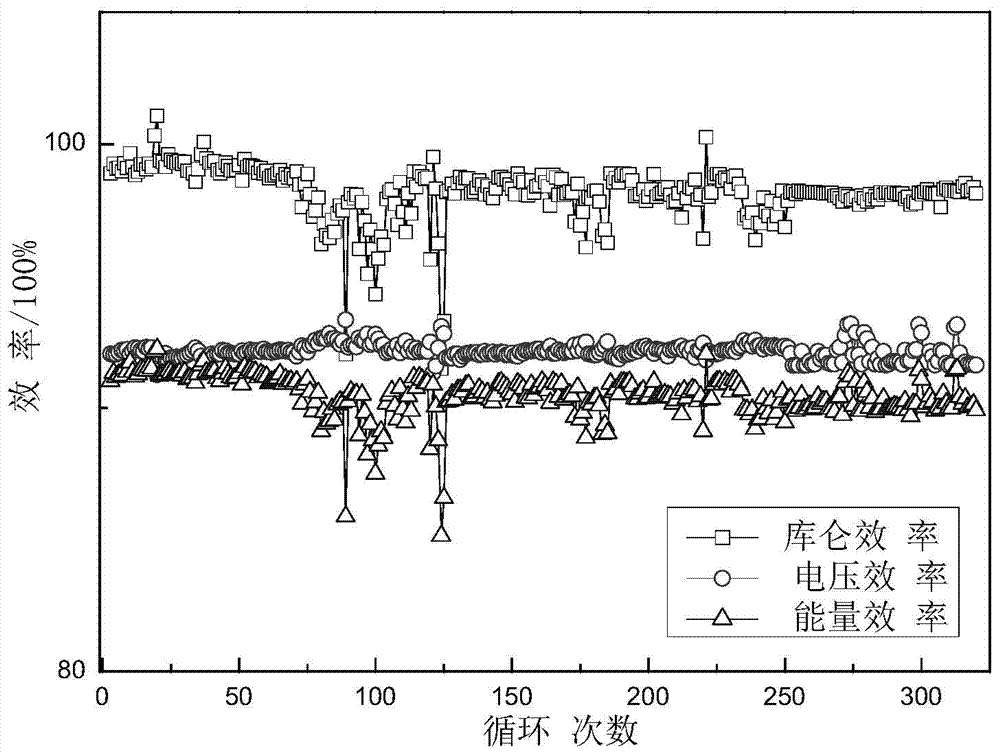

Embodiment 2

[0033] Preparation of cathode materials: (taking Ni, Mn mixed oxide as an example)

[0034] Put nickel acetate, manganese sulfate, potassium permanganate, and lithium sulfate with a molar ratio of 3:3:6:1 in an agate mortar and grind for about 0.5 hours. When the color of the system is no longer deepened, transfer the solid mixture to Put it into a small beaker, heat it in a water bath at (80±5)°C for about 10 hours, grind it finely, and calcinate it in a muffle furnace at a high temperature of 300°C for 3 hours, then grind it finely.

[0035] Preparation of positive electrode:

[0036] The prepared cathode material was mixed with acetylene black and PTFE (5% (w)) at a mass ratio of 75:15:10, and thoroughly ground with an agate mortar. Add an appropriate amount of ethanol, scrape evenly on 3x3cm with a blade 2 On the nickel foam, put it into a vacuum oven at 120°C to dry to constant weight, press it into thin sheets under a pressure of 10MPa, and the positive active material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com