Halloysite/lanthanon perovskite composite SCR catalyst and preparation method thereof

A technology of SCR catalyst and rare earth calcium, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the constraints on the industrial application and promotion of catalysts, and there is no high-efficiency SCR catalyst , affect the denitrification effect and other issues, and achieve the effect of facilitating catalytic activity, increasing lattice defects, and good gas permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

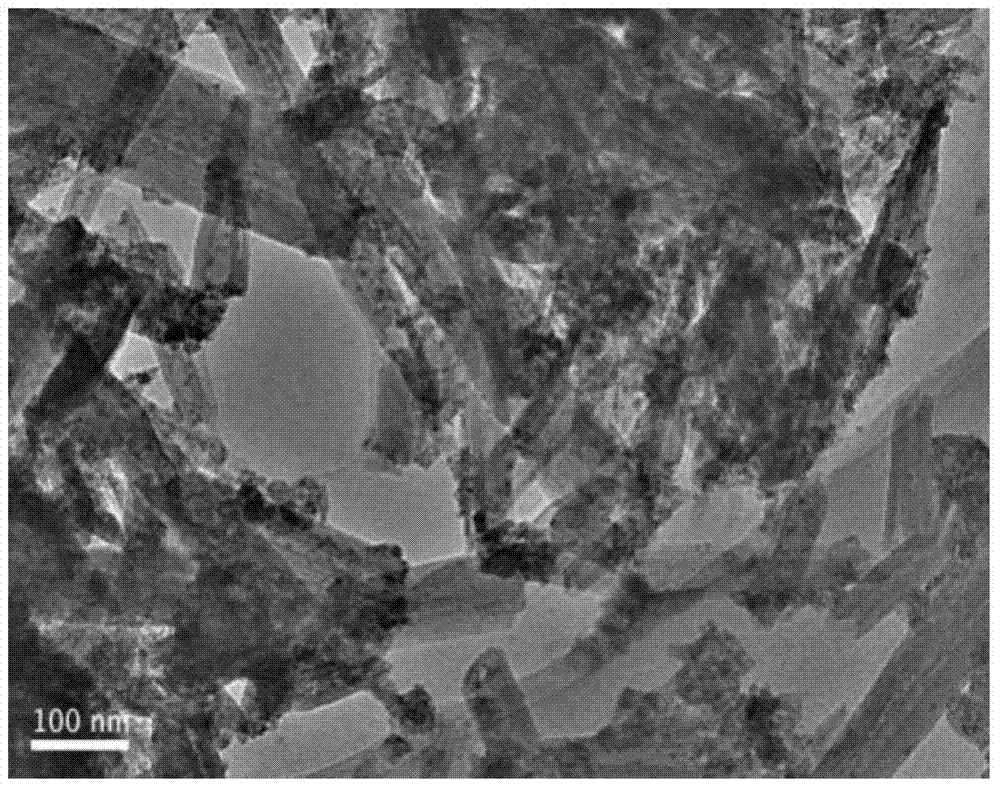

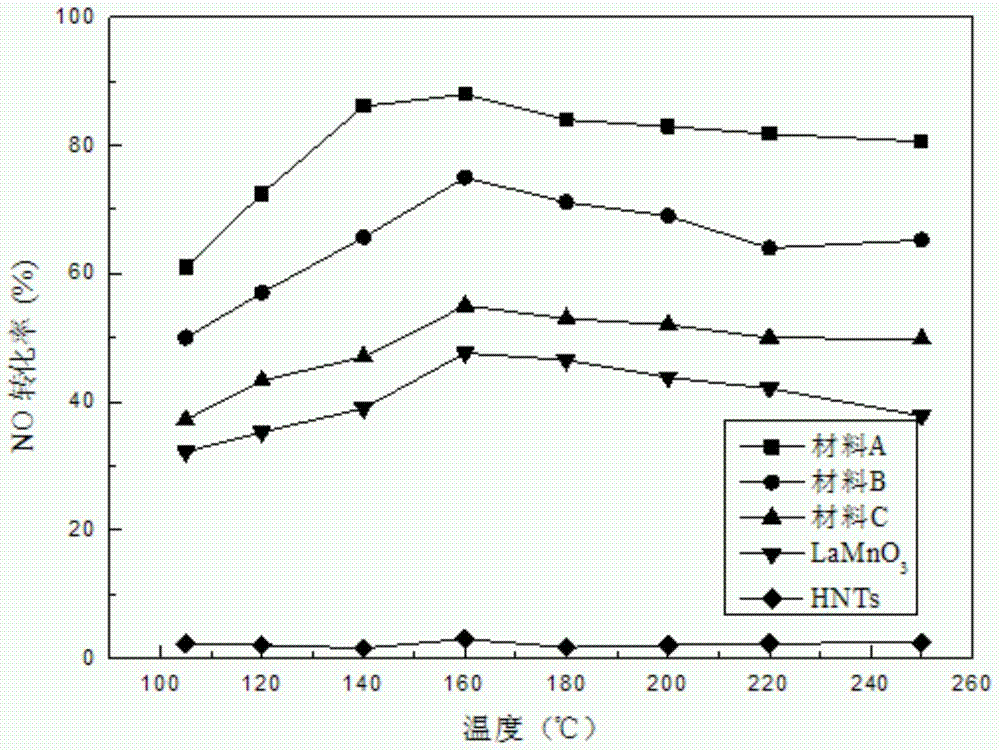

[0027] (1). Take 20g halloysite, dissolve it in 100mL deionized water, make the concentration of halloysite suspension be 10g / L, ultrasonic several minutes, add 2.69gLa(NO 3 ) 3 ·6H 2 O, 2.96g50%Mn(NO 3 ) 2 The solution was stirred and dissolved, and 3.48 g of citric acid was added into the mixed solution under continuous stirring, and 3 ml of dispersant ethylene glycol was added dropwise. It was placed in a water bath at a constant temperature of 80°C and reacted for 12 hours. Calcined at 550°C for 2 hours, granulated, passed through a 40-60 mesh sieve, and dried to obtain 10% LaMnO 3 / HNTs composite material, denoted as material A. The X-ray powder diffraction experiment was carried out on the obtained sample, and its morphology and structure were observed under a transmission electron microscope.

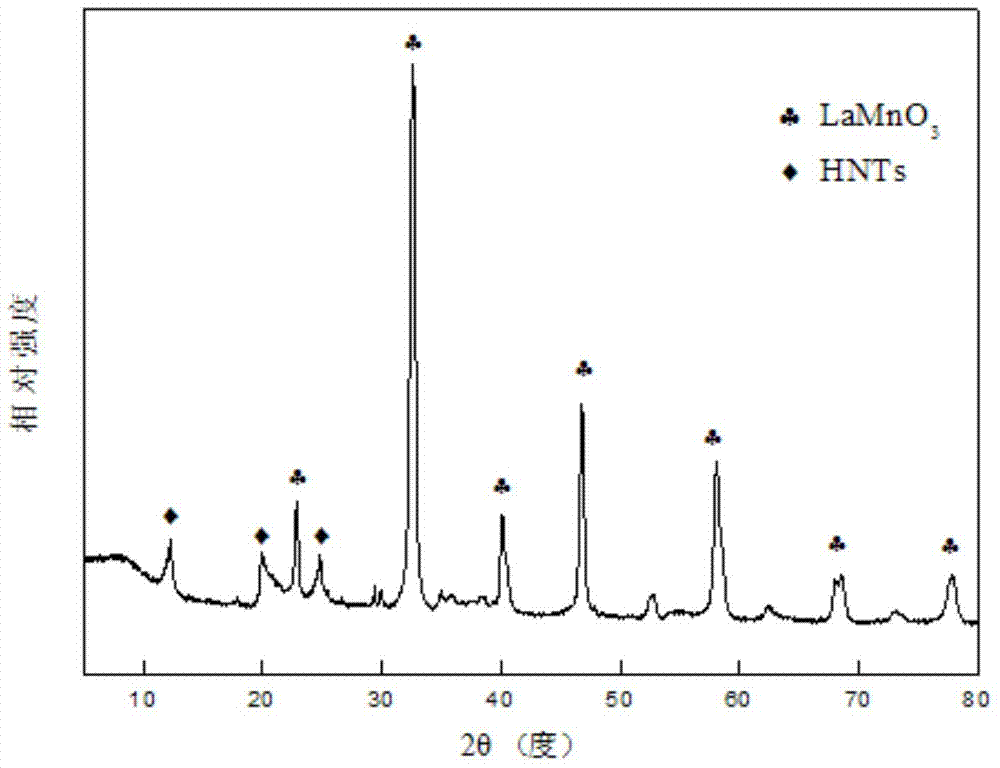

[0028] The LaMnO that prepares by embodiment 1 process method 3 / HNTs composite XRD such as figure 1 shown. It can be seen from the figure that the composite material ma...

Embodiment 2

[0033] Change La(NO 3 ) 3 ·6H 2 The amount of O is 1.35g, 50% Mn(NO 3 ) 2 The amount is 1.04g, the concentration of halloysite is 20g / L, weigh 5g sodium tripolyphosphate, 10ml dispersant methyl pentanol, put it in a water bath, keep the temperature at 60°C, stir for 18h, and calcined at 450°C 3h, granulate, pass through a 40-60 mesh sieve, and dry to obtain 5% LaMnO 3 / HNTs.

[0034] The follow-up SCR denitrification test was as in Example 1, and the results showed that at 160°C, the nitrogen oxide removal rate of the composite material prepared in Example 2 reached 82%.

Embodiment 3

[0036] Change La(NO 3 ) 3 ·6H 2 The amount of O is 1.35g, 50% Mn(NO 3 ) 2 The amount is 1.04g, the concentration of halloysite is 10g / L, 5g of citric acid and 7ml of dispersant methyl pentanol are weighed, placed in a water bath, kept at a constant temperature of 60°C, stirred for 18h, and calcined at 450°C for 3h. Granulate, pass through a 40-60 mesh sieve, and dry to obtain 20% LaMnO 3 / HNTs.

[0037] The follow-up SCR denitration test is as in Example 1. The results show that at 160°C, the nitrogen oxide removal rate of the composite material in Example 3 reaches 78%, and the effect is slightly lower than that of the materials in Example 1 and Example 2. It may be Partial agglomeration occurred after the loading increased, which affected the catalytic effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com