Nano calcium silicate-polyetheretherketone (PEEK) composite material and preparation method thereof

A nano-calcium silicate and polyetheretherketone technology, which is applied in medical science, prosthesis, etc., can solve the problems of unsatisfactory mechanical strength, affecting polymer properties, and inability to host osseointegration. Biologically active, integrative-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

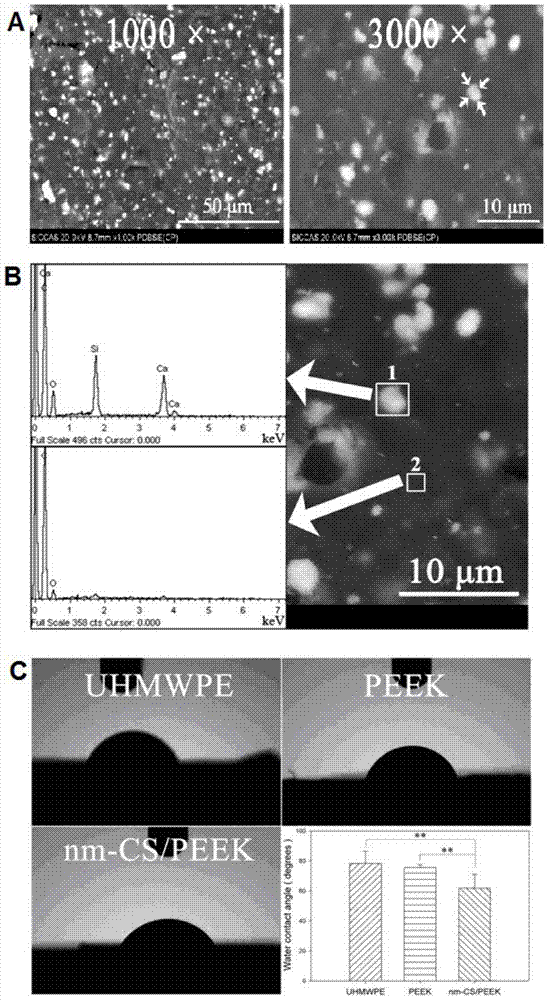

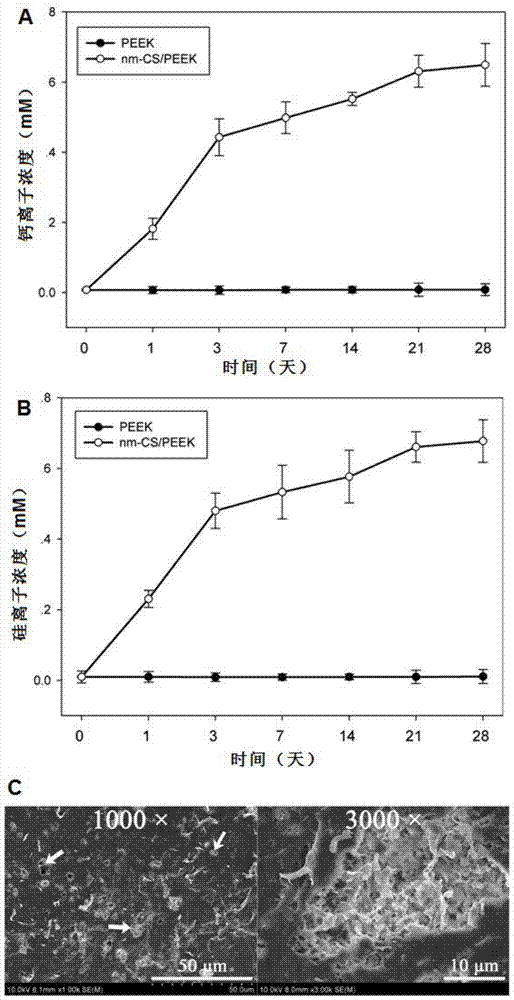

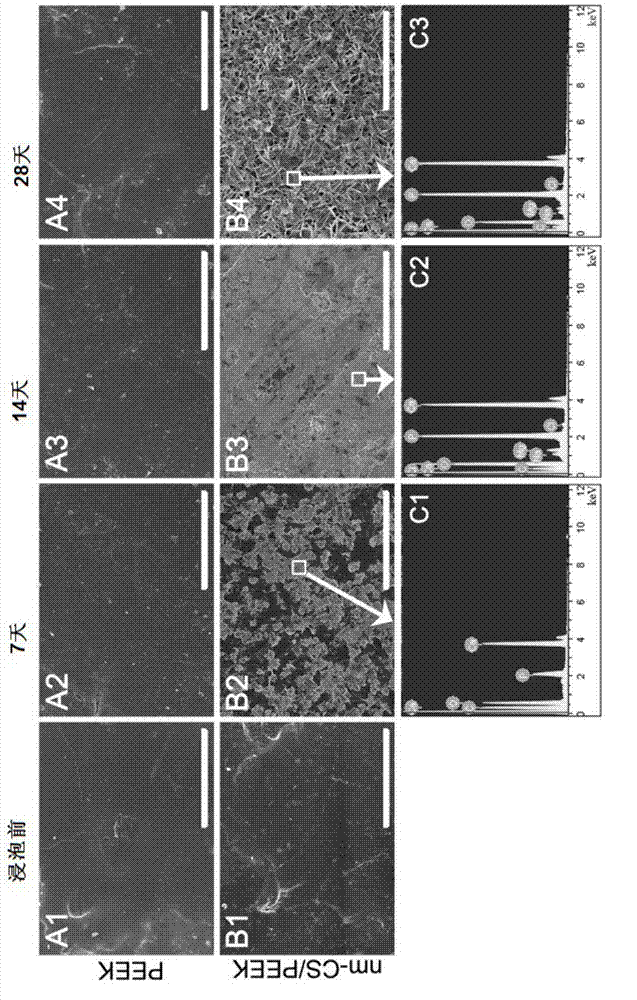

Method used

Image

Examples

Embodiment 1

[0029] (1) Materials and equipment required for the experiment

[0030] Material: PEEK powder (average particle size of 20μm, purchased from the UK Company); Ultra-high molecular weight polyethylene (UHMWPE) plates (molecular weight 2,000,000, purchased from Roechling Engineering Plastics, Germany); cell culture plates (Costar, Corning, USA); MC3T3-E1 cells (for this laboratory liquid nitrogen tank Stored cells); other reagents are commercially available analytical reagents.

[0031] Instruments: Ultra-clean workbench (BIO-HAZARD, VCM-420, Taiwan), electronic analytical balance (METTLERTOLEDO, AB204-E, Switzerland), electromagnetic stirrer (STUART, SM24, UK), high-speed ball mill (QM-3B, Nanjing T-BotaScietechInstruments&Equipment Ltd., China), injection molding machine (BA-300 / 050CD, Battenfeld, Belgium), scanning electron microscope (S-4800, Hitachi, Japan), energy dispersive spectrometer (X-Max, Horiba, Japan), Shape analyzer (JC-2000D3, ShanghaiZhongchengDigitalTechnologyCo.,...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 is that in the preparation process of the nm-CS / PEEK composite material provided in this embodiment, the volume ratio of nano calcium silicate powder and PEEK powder is 15:85.

Embodiment 3

[0054] The difference between this embodiment and Embodiment 1 is that in the preparation process of the nm-CS / PEEK composite material provided in this embodiment, the volume ratio of nano calcium silicate powder and PEEK powder is 25:75.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com