Core-shell structured quantum dot composite nanocrystalline fluorescence probe and preparation method thereof

A core-shell structure, fluorescent probe technology, applied in the field of preparation of nanomaterials, can solve the problems of unstable physical and chemical properties, luminescence properties are easily affected by the external environment, etc., to improve various properties, good stability and biological Compatibility, luminous efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

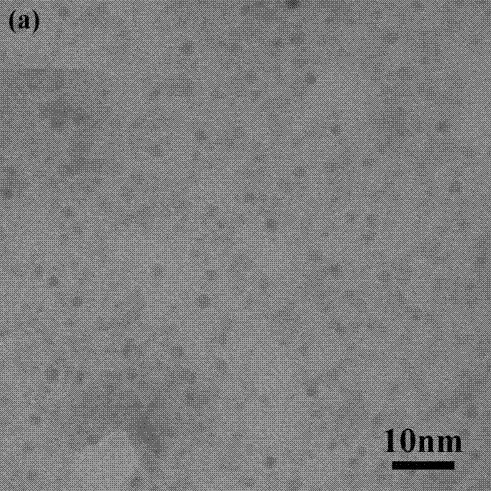

[0031] (1) Preparation of ZnSe quantum dot solution

[0032] Under nitrogen protection, 0.01g NaBH 4 Dissolve 0.0061g of Se powder in 2 mL of distilled water, heat to 40°C, and obtain NaHSe solution after completely dissolving; take 0.0439 g of Zn(Ac) 2 Dissolve in 20 mL of distilled water, add 0.0737 g of reduced glutathione after it is completely dissolved, and adjust the pH to 11.5 with 1 mol / L NaOH solution to obtain a Zn precursor solution; transfer the Zn precursor into a three-necked flask NaHSe solution was quickly injected under the protection of nitrogen, and the oil bath was refluxed at 100°C. After magnetic stirring for 1 h, it was taken out and quickly cooled to room temperature in the refrigerator to obtain a colorless and transparent solution, which was the prepared ZnSe QDs solution.

[0033] (2) Core-shell structure ZnSe@SiO 2 Preparation of Composite Nanocrystals

[0034] The prepared ZnSe QDs solution was separated and precipitated with isopropanol and di...

Embodiment 2

[0037] (1) Preparation of ZnSe quantum dot solution

[0038] Under nitrogen protection, 0.0085g NaBH 4 Dissolve 0.0060 g of Se powder in 2 mL of distilled water, heat to 40°C, and obtain NaHSe solution after completely dissolving; take 0.0351 g of Zn(Ac) 2 Dissolve in 20 mL of distilled water, add 0.0903 g of reduced glutathione after it is completely dissolved, and adjust the pH to 11.8 with 1 mol / L NaOH solution to obtain a Zn precursor solution; transfer the Zn precursor into three The NaHSe solution was quickly injected into the bottle under the protection of nitrogen, and the oil bath was refluxed at 100 °C. After magnetic stirring for 1.5 h, it was taken out and placed in the refrigerator to cool rapidly to room temperature to obtain a colorless and transparent solution, which was the prepared ZnSe QDs solution.

[0039] (2) Core-shell structure ZnSe@SiO 2 Preparation of Composite Nanocrystals

[0040] The prepared ZnSe QDs solution was separated and precipitated with...

Embodiment 3

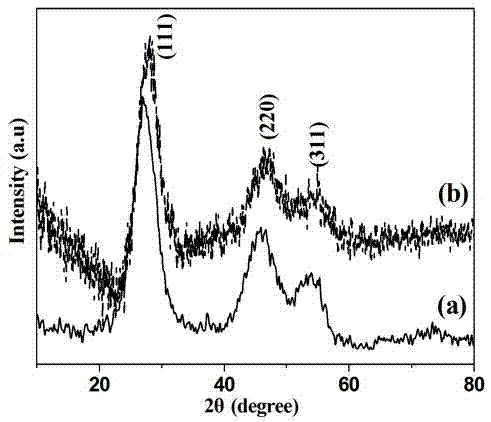

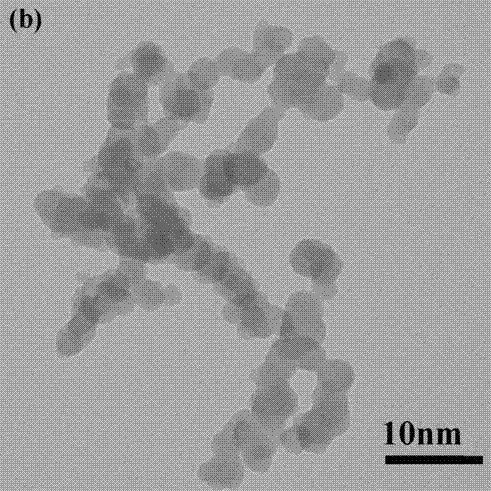

[0043] (1) Preparation of ZnSe@ZnS quantum dot solution

[0044] Firstly, ZnSe quantum dots were prepared by chemical co-precipitation method, and the preparation method was as described in the above-mentioned Example 1.

[0045] Take 15 mL of prepared ZnSe quantum dots, in which the concentration of ZnSe quantum dots is 2.7×10 -3 mol / L, add 0.0138 g Zn(Ac) 2 , 0.0277 g reduced glutathione and 0.01 g thiourea, adjust the pH value to 10.5 with the prepared NaOH solution with a concentration of 1 mol / L, under magnetic stirring, reflux the oil bath at 100°C, and react for 2 h after magnetic stirring Put it in the refrigerator and quickly cool it to room temperature to obtain light yellow water-soluble ZnSe@ZnS quantum dots with high luminous efficiency.

[0046] (2) Core-shell structure ZnSe@ZnS@SiO 2 Preparation of Composite Nanocrystals

[0047] The prepared ZnSe@ZnS QDs solution was separated and precipitated with isopropanol and dispersed into 15 mL of distilled water, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com