A kind of artistic flexible face brick and its construction method

A construction method and technology of facing bricks, which are applied in the directions of architecture, building structure, covering/lining, etc., can solve the problems of variable coefficient of expansion, linear expansion and contraction, large differences in temperature and thermal stress, poor weather resistance and waterproof air permeability, and flexibility. and poor crack resistance, to achieve the effect of low price, weather resistance, waterproof and breathable, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

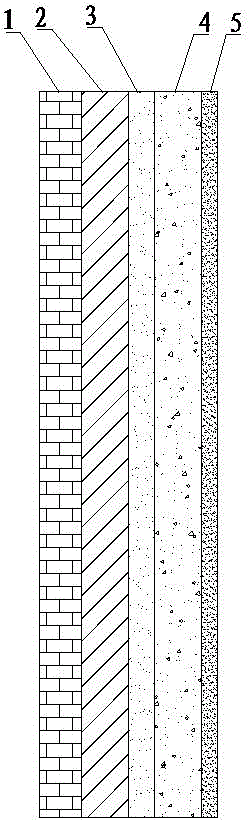

[0032] like figure 1As shown, a kind of art flexible surface tile, which comprises a caulking leveling layer 2 arranged on the outer surface of the base layer 1, the outer surface of the caulking leveling layer 2 is provided with a bottom glaze layer 3, and the bottom glaze layer 3 is The outer surface is provided with a face brick slurry layer 4, and the outer surface of the face brick slurry layer 4 is provided with a waterproof enamel layer 5;

[0033] The caulking leveling layer 2 is composed of 20kg of Portland cement, 5kg of ash calcium powder, 1.5kg of high molecular polymer, 0.5kg of polyvinyl alcohol powder, 0.4kg of hydroxybenzyl cellulose, 0.2kg of lignin, 0.1kg polypropylene staple fiber, 0.2kg organosilane powder, 2.0kg bentonite, 0.1kg starch ether, 15kg heavy calcium carbonate, and 0.2kg inorganic pigment;

[0034] The bottom glaze layer 3 is made of polyacrylic resin 30kg, acrylic resin 10kg, silica sol 2.0kg, antiseptic 0.1kg, defoamer 0.1kg, dispersant 0.5kg...

Embodiment 2

[0049] like figure 1 As shown, a kind of art flexible surface tile, which comprises a caulking leveling layer 2 arranged on the outer surface of the base layer 1, the outer surface of the caulking leveling layer 2 is provided with a bottom glaze layer 3, and the bottom glaze layer 3 is The outer surface is provided with a face brick slurry layer 4, and the outer surface of the face brick slurry layer 4 is provided with a waterproof enamel layer 5;

[0050] The caulking leveling layer 2 is composed of 25kg of Portland cement, 7kg of ash calcium powder, 2.5kg of high molecular polymer, 1kg of polyvinyl alcohol powder, 0.6kg of hydroxybenzyl cellulose, 0.3kg of lignin, and 0.3kg of polyvinyl alcohol. 0.2kg of propylene staple fiber, 0.3kg of organosilane powder, 3.0kg of bentonite, 0.2kg of starch ether, 20kg of heavy calcium carbonate, and 0.3kg of inorganic pigment;

[0051] The bottom glaze layer 3 is made of polyacrylic resin 40kg, acrylic resin 15kg, silica sol 2.5kg, antis...

Embodiment 3

[0066] like figure 1 As shown, a kind of art flexible face brick, it comprises the caulking leveling layer 2 that is arranged on the outer surface of the base layer 1, the outer surface of the caulking leveling layer 2 is provided with a bottom glaze layer 3, the bottom glaze layer 3 The outer surface is provided with a tile slurry layer 4, and the outer surface of the tile slurry layer 4 is provided with a waterproof enamel layer 5;

[0067] The caulking leveling layer 2 described therein is made of Portland cement 30kg, lime calcium powder 10kg, high molecular polymer 3kg, polyvinyl alcohol powder 1kg, hydroxybenzyl cellulose 0.7kg, lignin 0.4kg, polypropylene 0.2kg of short fiber, 0.4kg of organosilane powder, 3.5kg of bentonite, 0.4kg of starch ether, 23kg of heavy calcium carbonate, and 0.4kg of inorganic pigment;

[0068] Described bottom glaze layer 3 is made of polyacrylic resin 50kg, acrylic resin 20kg, silica sol 5kg, preservative 0.5kg, defoamer 0.3kg, dispersant 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com