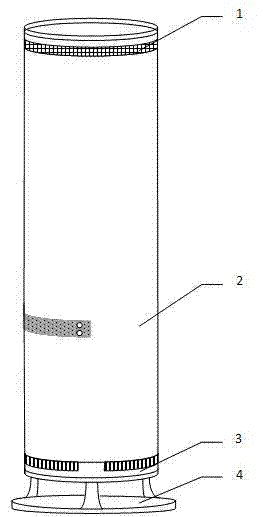

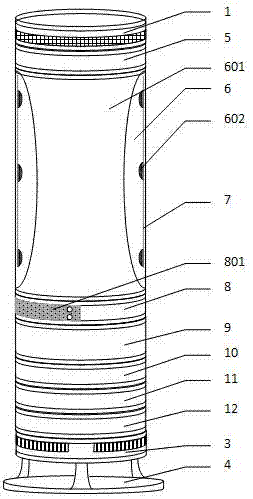

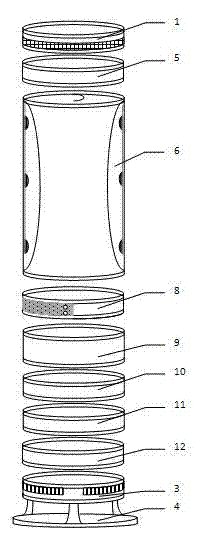

Stacked type intelligent air treatment system

An air handling system, a layered technology, applied in air conditioning systems, heating and ventilation control systems, heating and ventilation safety systems, etc., can solve the problems of inability to remove inorganic dust particles and dust, reduced equipment purification capacity, and inability to wash with water, etc. Achieve the effect of improving the utilization rate of the light source, increasing the light reaction area, and avoiding human operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1: Utilize this system to purify formaldehyde and TVOC

[0060] In order to verify the purification function of the system for indoor air, the applicant tested the glass airtight box (2.5 m 3 ) carried out the degradation experiments of formaldehyde and TVOC, and collected the data results of 10 sets of repeated experiments. The results showed that the content of formaldehyde and TVOC in the air in the confined space was significantly reduced, and the results are shown in the table below:

[0061]

[0062] It can be drawn from Table 1 that, through the intelligent air treatment system of the present invention, the content of formaldehyde and TVOC in the air is significantly reduced, and the air is purified.

Embodiment 2

[0063] Embodiment 2: Utilize this system to emit functional volatiles

[0064] In order to verify the ability of the system to emit functional volatiles, the applicant conducted a heating and emission test of functional volatiles in the laboratory, measured the temperature in the odor source box before and after the system worked, and carried out a test on the functional volatiles emitted by the system. collected and analyzed. GC-MS analysis results such as Figure 14 and Figure 15 shown, from Figure 14 and Figure 15 It can be seen from the figure that the temperature in the flavor source box was 28°C and 57°C before and after the system was started, and the flavor source solid added to the flavor source box began to release volatiles of different concentrations under heating conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com