Preparation method of flexible anode of lithium-selenium battery

A battery and flexible technology, applied in the direction of battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of reduced relative content of active materials, limited battery energy density, poor electrochemical performance of batteries, etc., to achieve volume expansion and good performance. Effect of ion transport ability and conductivity, high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

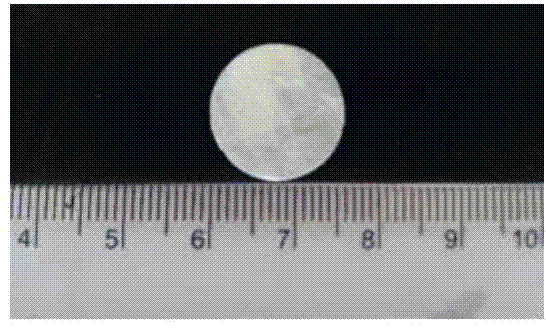

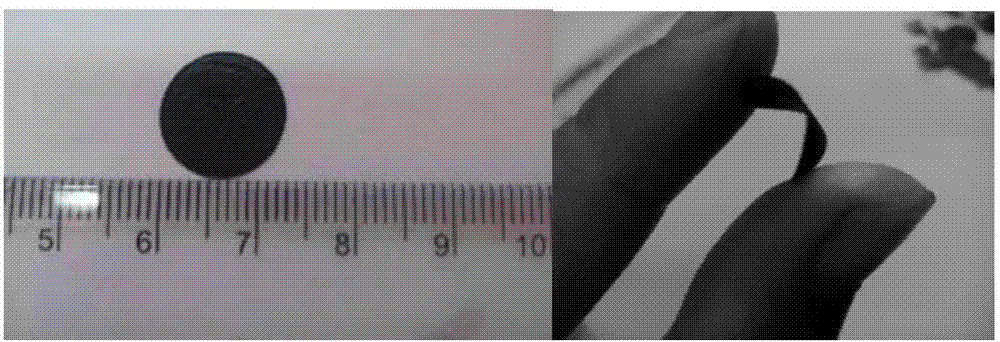

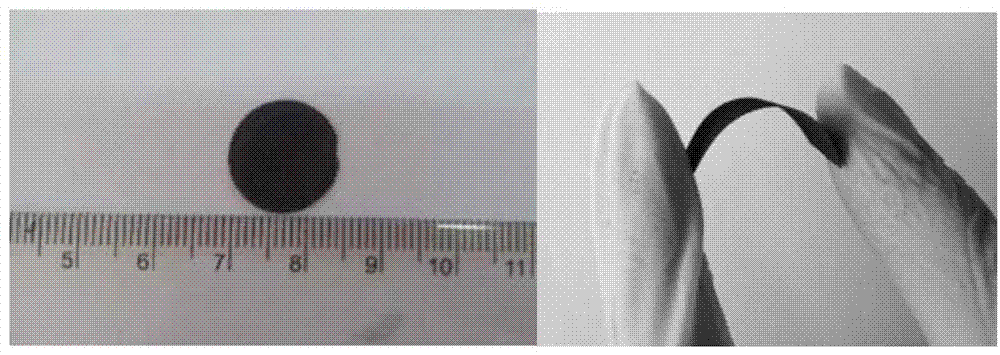

[0034] Wash the bacterial cellulose membrane (stored in the refrigerator) with deionized water, pre-freeze the sample with liquid nitrogen in a freeze dryer, and then freeze-dry it at a temperature of -48°C and a pressure of 0.04 mbar for 24 hours to obtain bacteria Cellulose membrane, and then knock the bacterial cellulose membrane into discs. 0.89g Zn(NO 3 ) 2 ·6H 2 O. Dissolve 0.49g of bis-methylimidazole in 100mL of DMF to prepare ZIF-8 synthetic solution. Soak the bacterial fiber membrane disc in the ZIF-8 synthetic solution with a concentration of 0.03mol / L. Under the hydrothermal reaction. After reacting for 24 hours, the product was washed and freeze-dried for another 24 hours to obtain a ZIF-8-coated bacterial cellulose membrane material. The obtained product was placed in a tube furnace, in an argon or nitrogen flow, at a heating rate of 5 °C / min, carbonized at 800 °C and kept for 4 hours, to obtain a specific surface area of 1500 m 2 / g, nitrogen mass content i...

Embodiment 2

[0042] Clean the bacterial cellulose membrane (stored in the refrigerator) with deionized water, pre-freeze the sample with liquid nitrogen in a freeze dryer, and then freeze-dry it at a temperature of -50 ° C and a pressure of 0.06 mbar for 20 hours to obtain bacteria Cellulose membrane, and then knock the bacterial cellulose membrane into discs. 0.89g Zn(NO 3 ) 2 ·6H 2 O. Dissolve 0.74g of bis-methylimidazole in 100mL DMF to prepare ZIF-8 synthetic solution. Soak the bacterial fiber membrane disk in the ZIF-8 synthetic solution with a concentration of 0.03mol / L. Under the hydrothermal reaction. After reacting for 18 hours, the product was washed and then freeze-dried for 20 hours to obtain a ZIF-8-coated bacterial cellulose membrane material. The obtained product was placed in a tube furnace, and in an argon or nitrogen flow, at a heating rate of 5°C / min, carbonized at 900°C and kept for 3h to obtain a specific surface area of 1400m 2 / g, nitrogen mass content is 14% ...

Embodiment 3

[0044] Bacterial cellulose membranes washed with deionized water (stored in a refrigerator), pre-frozen samples with liquid nitrogen in a freeze dryer, and then freeze-dried at a temperature of -30°C and a pressure of 0.01 mbar for 24 hours to obtain Bacterial cellulose membrane, and then knock the bacterial cellulose membrane into discs. 1.48g Zn(NO 3 ) 2 ·6H 2 O. Dissolve 0.82g of bis-methylimidazole in 100mL DMF to prepare ZIF-8 synthetic solution. Soak the bacterial fiber membrane disk in the ZIF-8 synthetic solution with a concentration of 0.05mol / L. Under the hydrothermal reaction. After reacting for 18 hours, the product was washed, and then freeze-dried for 24 hours to obtain a ZIF-8-coated bacterial cellulose membrane material. The obtained product was placed in a tube furnace, in an argon or nitrogen flow, at a heating rate of 5 °C / min, carbonized at 800 °C and kept for 4 hours, to obtain a specific surface area of 1500 m 2 / g, a nitrogen mass content of 12% a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com