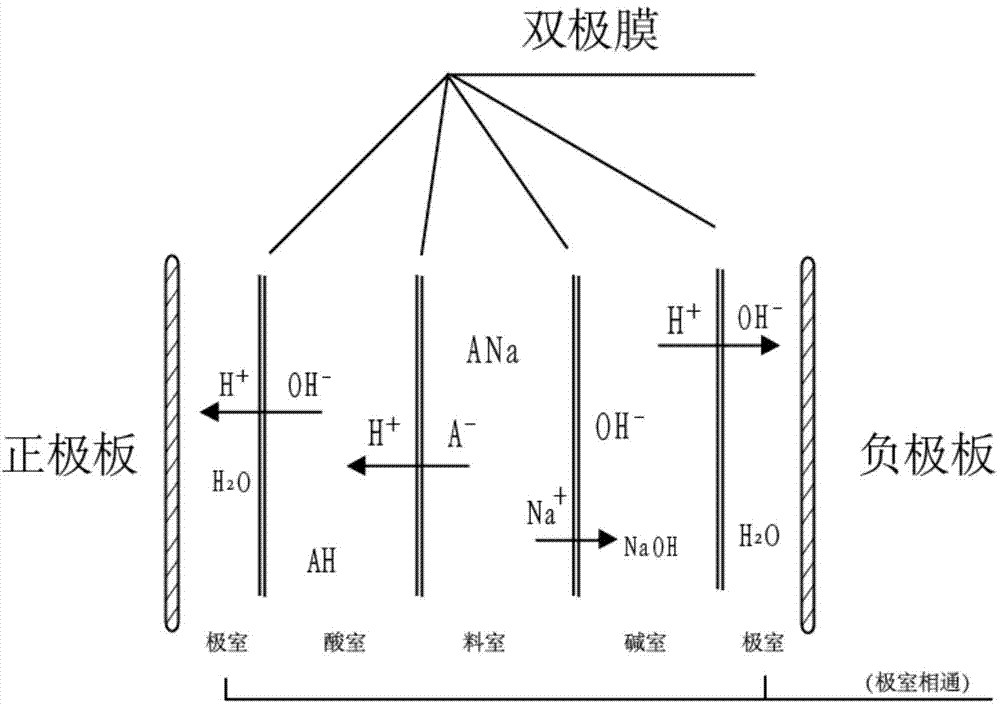

Method of preparing sarcosine by bipolar membrane electrodialysis process

A bipolar membrane electrodialysis and sarcosine technology, which is applied in the field of preparation of sarcosine, can solve the problems of inexhaustibility, increased cost, secondary pollution, etc., and achieve the effect of low operating cost, good quality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add hydroxyacetonitrile with a mass fraction of 50% to the reaction vessel, stir, cool to a temperature less than 10°C, add dropwise a 25% mass fraction of methylamine solution, the molar ratio of hydroxyacetonitrile to methylamine is 1:1.2, During the dropping process, the temperature is controlled to be less than 15°C, the dropping process lasts for 1 hour, and the stirring is continued for 1 hour after the dropping is completed, to obtain a methylaminoacetonitrile solution;

[0025] Add sodium hydroxide to the obtained methylaminoacetonitrile solution, and hydrolyze to obtain sodium methylaminoacetate, ie, a mixed solution of sodium sarcosinate and sodium hydroxide, and set the reaction temperature at 100°C.

[0026] Dilute the 1 mol sodium sarcosinate mixture obtained above to 450g, control the temperature at 30°C, turn on the power supply under the conditions of 5.5A current and 15cm / s flow rate, and stop the operation when the conductance value reaches 2000us / cm fo...

Embodiment 2

[0029] The mixed solution of 1mol of sodium sarcosinate was diluted to 750g, other conditions were the same as in Example 1, and the conductivity value reached 2000us / cm in about 1 hour when electrodialysis was used, and 62.5g of sodium sarcosinate was obtained, with a yield of 70% and a content of 99.3%.

Embodiment 3

[0031] The sodium sarcosinate mixed solution of 1mol is diluted to 750g, and electric current is 10A, and other conditions are identical with embodiment 1, and current dialysis takes 40 minutes, and conductance value reaches 2000us / cm, obtains sarcosine 54.5g, yield 61.2%, content was 97.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com