Machining method for electromagnetic shielding woven fabric with core-shell alloy structure

A technology of electromagnetic shielding and processing methods, which is applied in the processing of electromagnetic shielding woven fabrics, the processing of electromagnetic shielding plain cotton fabrics, and the preparation of core-shell copper-silver alloys. Low efficiency and other problems, to achieve the effect of broadening the shielding wavelength range, improving shielding effectiveness, and improving bonding fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

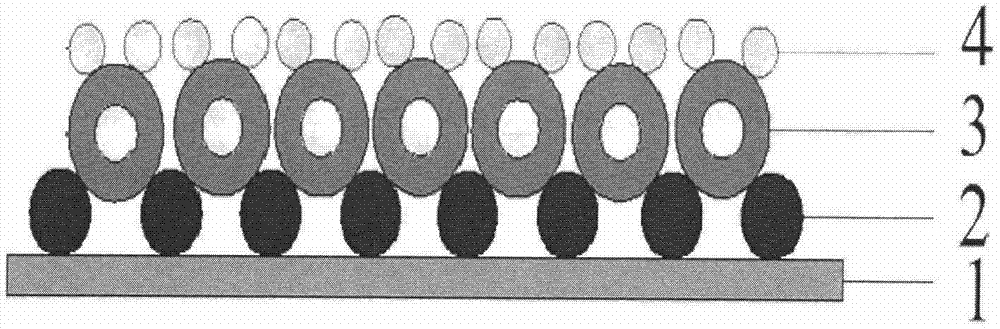

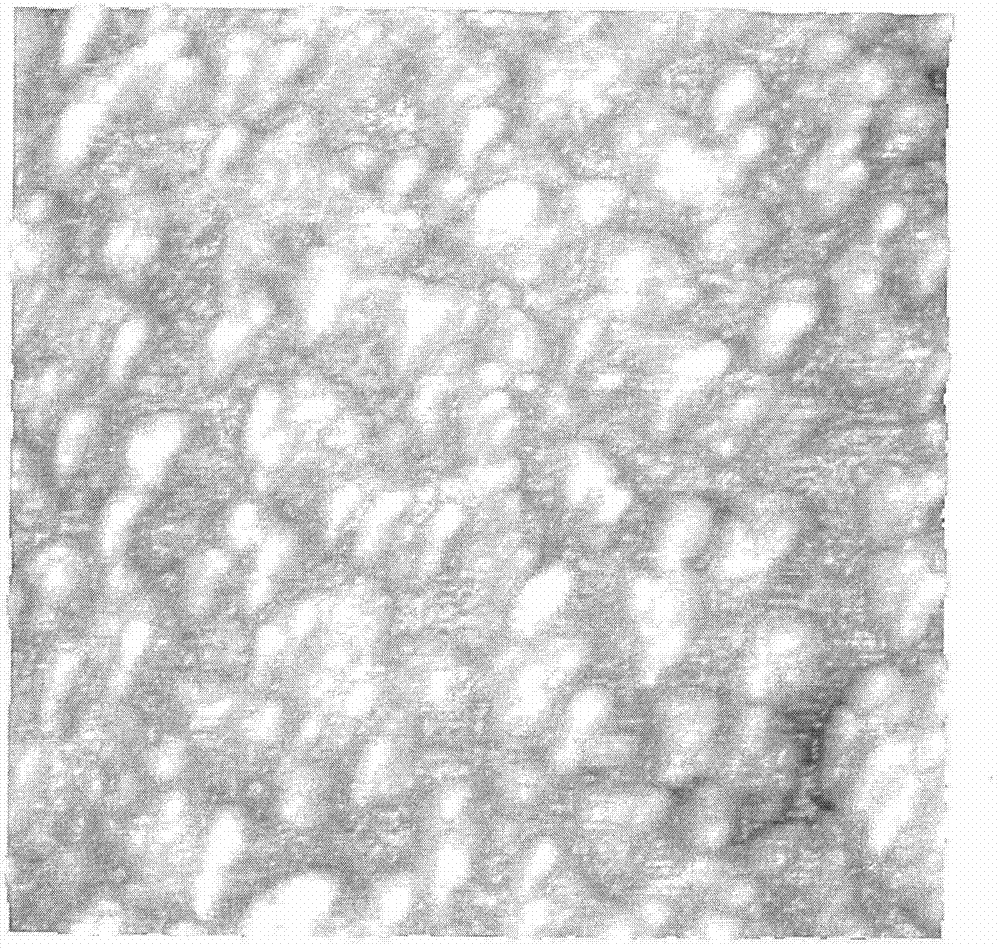

Embodiment 1

[0021] Put the plain cotton fabric with 60 warp yarns and 60 weft yarns into the plasma deposition device, the target position is empty, vacuumize to 0.0001Pa, add the reaction gas as argon, and the plasma power is 20W, and clean for 10 minutes; then The pretreated plain cotton fabric is put into the plasma deposition chamber, evacuated to 0.00005Pa, filled with oxygen, and the reaction pressure is controlled to 0.1Pa. Copper and copper oxide are used as targets, and the radio frequency plasma power is 200W. Cuprous oxide particles of 552nm; re-evacuated, filled with 0.5Pa of helium, copper target power 16W, silver target reaction power 160W, copper target reaction temperature 100°C, silver target reaction temperature 250°C, co-deposition 15 Minutes, then the copper target is plasma deposited for 30 minutes alone, the power is 100W; the target is changed to copper oxide, the vacuum is evacuated to 0.00001Pa, and the sputtering time is 30 minutes, the obtained fabric Such as ...

Embodiment 2

[0023] Put the plain cotton fabric with 60 warp yarns and 50 weft yarns into the plasma deposition device, the target position is empty, vacuumize to 0.00001Pa, add the reaction gas as argon, and the plasma power is 20W, and clean for 10 minutes; then The pretreated plain cotton fabric is put into the plasma deposition chamber, evacuated to 0.00005Pa, filled with oxygen, and the reaction pressure is controlled to 0.1Pa. Copper and copper oxide are used as targets, and the radio frequency plasma power is 200W. Cuprous oxide particles of 552nm; re-evacuated, filled with 0.5Pa helium, copper target power 16W, silver target reaction power 180W, copper target reaction temperature 100°C, silver target reaction temperature 250°C, co-deposition 15 Minutes, then the copper target is plasma deposited for 30 minutes alone, the power is 100W; the target is changed to copper oxide, the vacuum is evacuated to 0.00001Pa, and the sputtering time is 30 minutes, the obtained fabric Such as fi...

Embodiment 3

[0025] Put the plain cotton fabric with 40 warp yarns and 40 weft yarns into the plasma deposition device, the target position is empty, vacuumize to 0.00005Pa, add the reaction gas as argon, and the plasma power is 20W, and clean for 10 minutes; then The pretreated plain cotton fabric is put into the plasma deposition chamber, evacuated to 0.00001Pa, filled with oxygen, and the reaction pressure is controlled to 0.1Pa. Copper and copper oxide are used as targets, and the radio frequency plasma power is 200W. Cuprous oxide particles of 573nm; re-evacuated, filled with 0.5Pa helium, copper target power 20W, silver target reaction power 200W, copper target reaction temperature 100°C, silver target reaction temperature 250°C, co-deposition 15 Minutes, then the copper target is plasma deposited for 30 minutes alone, the power is 100W; the target is changed to copper oxide, the vacuum is evacuated to 0.00001Pa, and the sputtering time is 30 minutes, the obtained fabric Such as fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com