Negative plate and preparation method thereof as well as lithium ion secondary battery using same

A negative electrode and lithium-ion technology, applied in the field of lithium-ion secondary batteries, can solve problems such as hindering the transfer of lithium ions between electrolytes and negative electrodes, reducing the performance of lithium-ion secondary batteries, and being difficult to effectively absorb electrolytes, etc., to achieve improved Charge-discharge speed and rate charge-discharge capacity, volume expansion and shrinkage reduction, and the effect of avoiding electrode swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

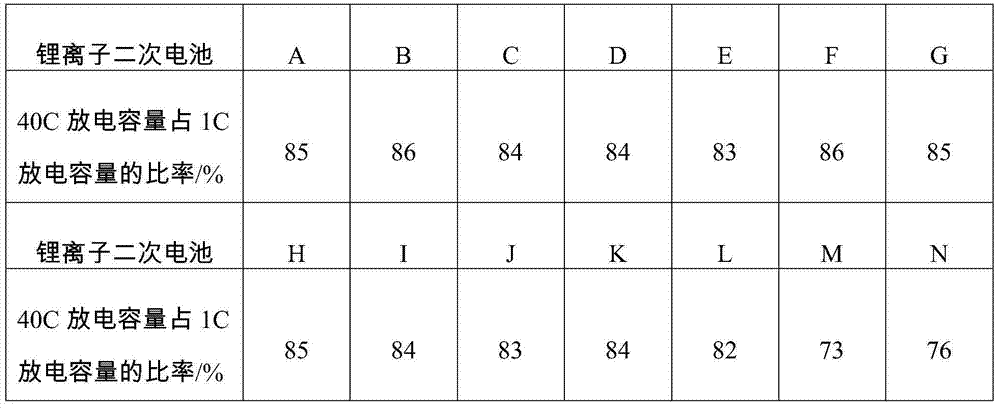

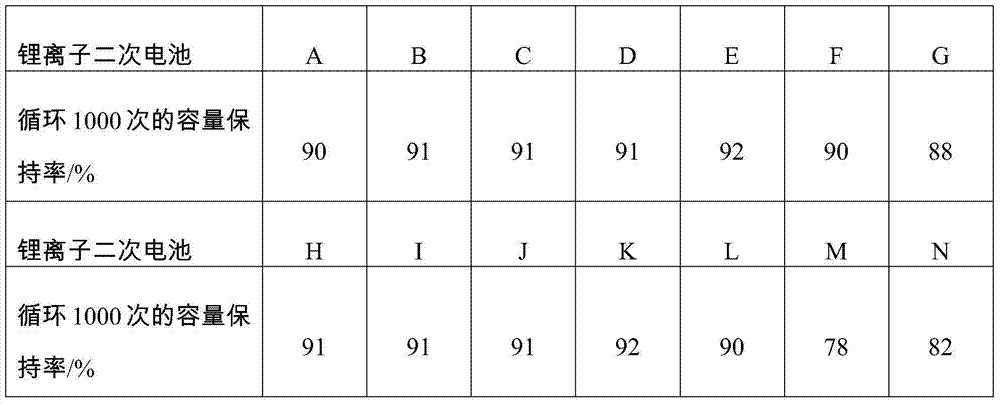

Examples

Embodiment 1

[0045] (1) Dissolve 13g of polyvinylidene fluoride completely in 1200g of N-methylpyrrolidone, and then add 87g of polyvinylidene fluoride with a specific surface area of 60m 2 The graphene of / g is mixed uniformly to form the first slurry;

[0046] (2) Dissolve 5g of sodium carboxymethyl cellulose in 100g of water, after standing still for 2 hours, add 85g of soft carbon and 5g of conductive carbon black and mix well, then add emulsion containing 5g of styrene-butadiene rubber, mix well to form soft carbon material slurry material; the above-mentioned soft carbon material slurry is evenly coated on the copper foil, and dried at 100°C to form a soft carbon material layer with a thickness of 30 μm; by weight, the soft carbon material layer includes 5wt% carboxymethyl fiber Sodium plain, 5wt% styrene-butadiene rubber, 5wt% conductive carbon black and 85wt% soft carbon;

[0047] (3) Evenly coat the first slurry on the above-mentioned soft carbon material layer, dry at 120°C to...

Embodiment 2

[0049] (1) Completely dissolve the emulsion containing 18g of polytetrafluoroethylene in 1600g of deionized water, and then add 82g of it with a specific surface area of 100m 2 / g of carbon nanotubes mixed uniformly to form the first slurry;

[0050] (2) Dissolve 3g of polyacrylic acid and 4g of polyacrylate latex in 85g of deionized water, then add 90g of soft carbon and 3g of acetylene black and mix evenly to form a soft carbon material slurry; spread the above soft carbon material slurry evenly on On the copper foil, dry at 100 ℃ to form a soft carbon material layer with a thickness of 50 μm; by weight, the soft carbon material layer includes 3wt% polyacrylic acid, 4wt% polyacrylate latex, 3wt% acetylene black and 90wt% soft carbon;

[0051] (3) Evenly coat the first slurry on the above-mentioned soft carbon material layer, dry at 120°C to form an infiltrating conductive coating with a thickness of 8 μm, and then obtain the negative electrode sheet B by rolling and sheet...

Embodiment 3

[0053] (1) Completely dissolve 10g sodium carboxymethylcellulose and 10g sodium alginate in 1800g deionized water, then add 80g 2 The carbon nanotube fibers of / g are mixed uniformly to form the first slurry;

[0054] (2) Completely dissolve 1g of sodium alginate in 110g of deionized water, then add 96g of soft carbon and 1g of carbon nanotubes and mix evenly, then add an emulsion containing 2g of polytetrafluoroethylene to form a soft carbon material slurry; The carbon material slurry is evenly coated on the copper foil, and dried at 100°C to form a soft carbon material layer with a thickness of 60 μm; by weight, the soft carbon material layer includes 1wt% sodium alginate, 2wt% polytetrafluoroethylene Vinyl fluoride, 1wt% carbon nanotubes and 96wt% soft carbon;

[0055] (3) Evenly coat the first slurry on the above-mentioned soft carbon material layer, dry at 120°C to form an infiltrated conductive coating with a thickness of 10 μm, and then obtain the negative electrode sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com