Polyaryletherketone quadripolymer and preparation method thereof

A tetrapolymer, polyaryletherketone technology, applied in the field of polyaryletherketone, can solve the problem of poor adhesion to metal substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0093] The invention provides a kind of preparation method of poly(aryl ether ketone tetrapolymer), comprising the following steps:

[0094] The first compound, the second compound, the third compound and the fourth compound are subjected to a polycondensation reaction in a solvent to obtain a polyaryletherketone tetrapolymer;

[0095] The first compound is a bisphenol compound;

[0096] The second compound is a dihalogen compound containing a benzene ring or a dinitro compound containing a benzene ring;

[0097] The third compound is a bisphenol compound, a compound containing an imidazolone structure or a phenol compound containing a secondary amino group;

[0098] The compound containing imidazolone structure includes imidazolone, benzimidazolone, 5-methylbenzimidazolone, 5-aminobenzimidazolone, 5-nitrobenzimidazolone, 5,6-dimethyl Benzimidazolone, 5,6-diaminobenzimidazolone, 5-benzoylbenzimidazolone and 5-methoxybenzimidazolone;

[0099] The phenolic compounds containin...

Embodiment 1

[0138] Add 0.268g (0.002mol) benzimidazolone, 2.547g (0.008mol) phenolphthalein, 0.671g (0.003075mol) 4,4'- difluorobenzophenone, 1.234g (0.007175 mol) 2,6-dichlorobenzonitrile, 1.589g potassium carbonate, 15g sulfolane and 20mL toluene, heat to 120°C to azeotropically remove water, keep warm for 1.5h, remove toluene, continue to heat to 210°C, react for 2.5h, cool down, Add 20mL DMAc to dilute, and precipitate in ethanol / water. After the precipitate is filtered and crushed, it is boiled and washed 5 times in deionized water to remove impurities such as inorganic salts and reaction solvents, and obtain a polyaryletherketone quaternary copolymer with the structure of formula IV thing;

[0139]

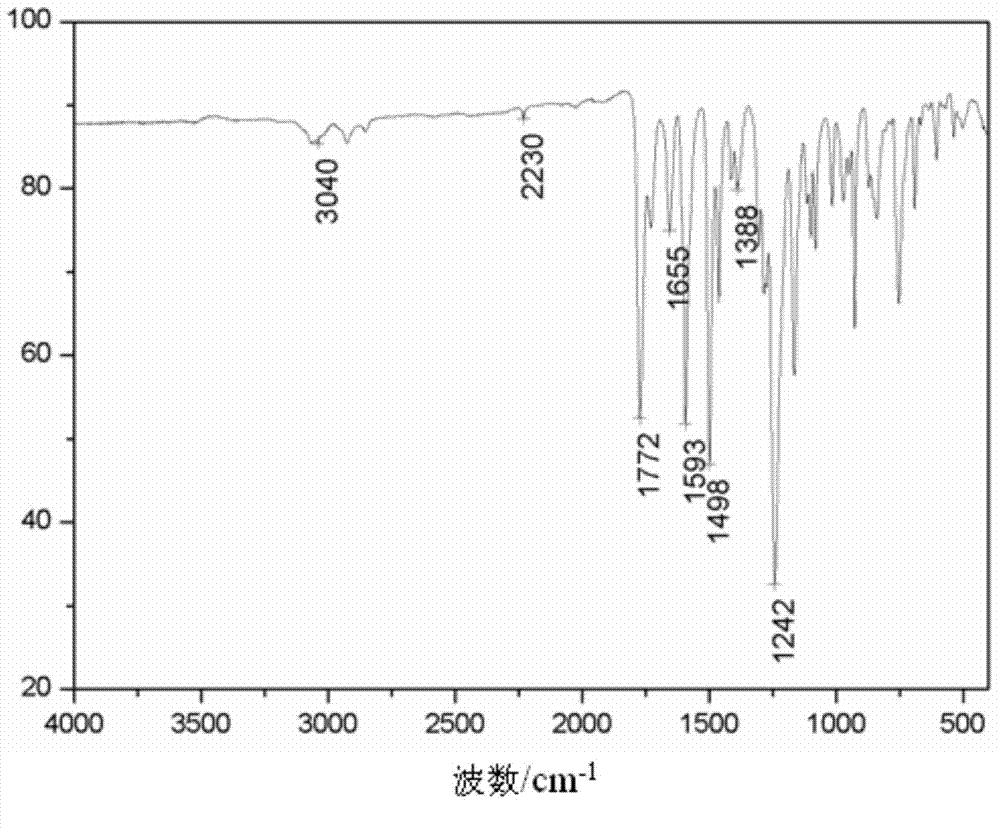

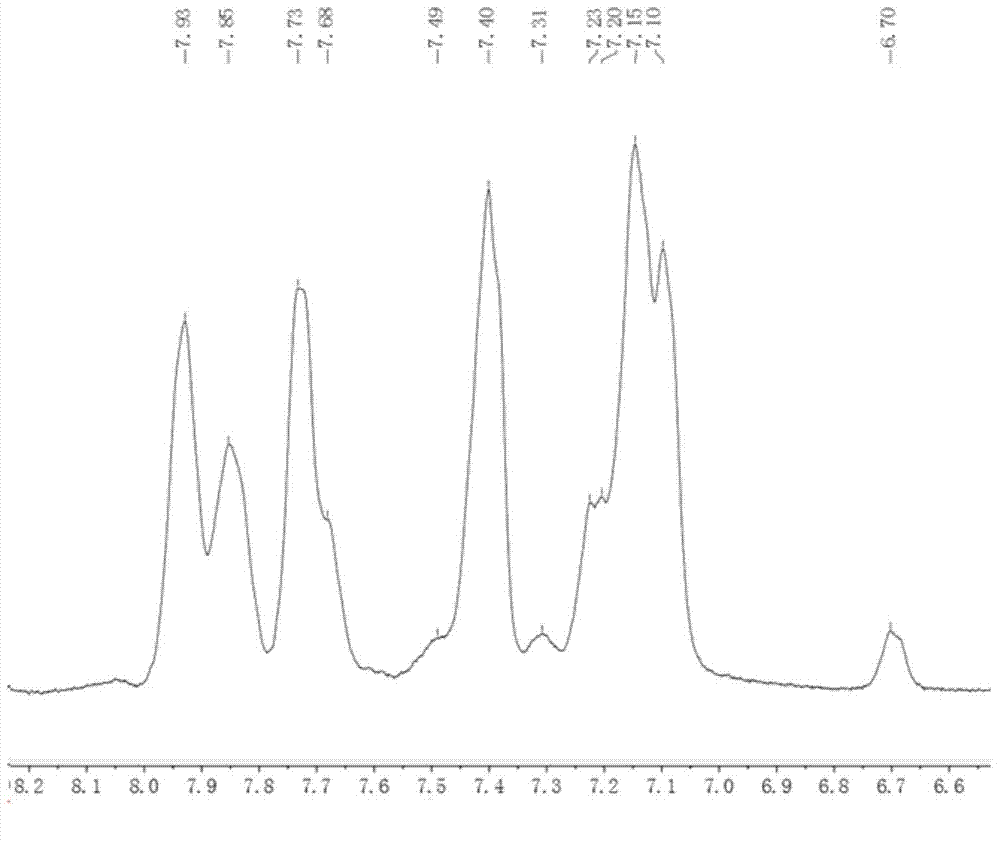

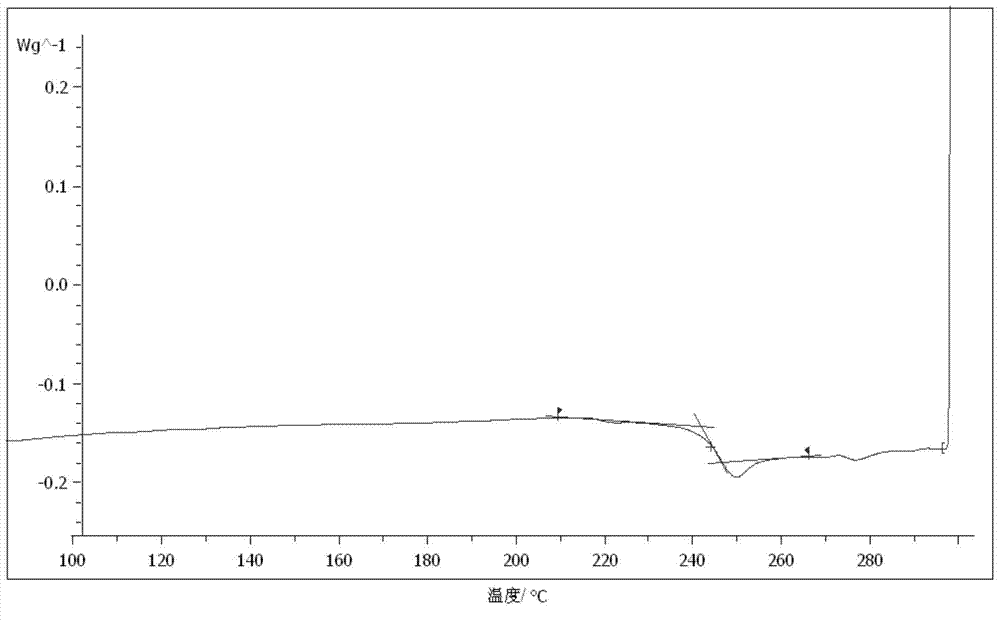

[0140] The present invention carries out infrared, nuclear magnetic resonance hydrogen spectrum, DSC, TGA test to the polyaryletherketone tetrapolymer obtained in the present embodiment 1, and the test chart is respectively as follows figure 1 , figure 2 , image 3 with Figure ...

Embodiment 2

[0148] 1.592g (0.005mol) of phenolphthalein, 0.671g (0.005mol) of benzimidazolone, 1.091g (0.005mol) of difluorobenzophenone, 0.860g (0.005mol) of 2,6 - Dichlorobenzonitrile, the catalyst is a mixed base, the mixed base includes 2.763g potassium carbonate and 1.060g sodium carbonate, 10g sulfolane, 5g diphenyl sulfone and 25mL toluene, heated to 130°C to azeotropically remove water, keep warm for 2h, remove Toluene, continue heating to 200°C, react for 5h, cool down, add 20mL DMAc to dilute, precipitate in ethanol / water, filter and pulverize the precipitate, wash it in deionized water for 7 times, remove impurities such as inorganic salts and reaction solvents, The polyaryletherketone tetrapolymer having the structure of formula VIII after removing the terminal groups was obtained, and the glass transition temperature was 279°C.

[0149]

[0150] Take 0.4000 g of the polyaryletherketone tetrapolymer having the structure of formula VIII after removing the terminal group, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com