Method for removing nitrogen-containing compounds in oil products by virtue of eutectic solvent extraction

A technology of deep eutectic solvent and nitrogen compound, which is applied in the field of chemical engineering, can solve the problems of high preparation cost and limit the large-scale application of ionic liquid extraction denitrification technology, and achieve low preparation cost, less pollution and high removal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Straight-run diesel oil (nitrogen content: 205 μg / g) and choline chloride / oxalic acid deep eutectic solvent (the molar ratio of choline chloride and oxalic acid is 1:1, and the freezing point is 34°C) at 40°C Single-stage extraction is carried out in a mixing and settling tank, and the mass flow ratio of straight-run diesel oil to deep eutectic solvent is 1:1. The raffinate oil was collected, washed with water, and dried to obtain denitrogenated oil (nitrogen content: 9.8 μg / g), the denitrogenation rate was 95.2%, and the yield of denitrogenated oil was 99.5%. Re-extracting the extract solution with n-hexane at 40°C to remove nitrogen-containing compounds therein, and then evaporating to remove residual n-hexane to obtain a regenerated choline chloride / oxalic acid deep eutectic solvent.

Embodiment 2

[0050] Put lubricating oil base oil (nitrogen content: 1390 μg / g) and choline chloride / urea deep eutectic solvent (the molar ratio of choline chloride and urea is 1:2, and the freezing point is lower than 25°C) at 35°C in Three-stage countercurrent extraction is carried out in the packed tower, and the mass flow ratio of deep eutectic solvent and lubricating oil is 1:1. The raffinate oil was collected, washed with water, and dried to obtain denitrogenated oil (nitrogen content: 48.7 μg / g), the denitrogenation rate was 96.5%, and the yield of denitrogenated oil was 99.1%. The extract was back-extracted with n-heptane at 50° C. to remove nitrogen-containing compounds therein, and then evaporated to remove the residual n-heptane to obtain a regenerated choline chloride / urea deep eutectic solvent.

Embodiment 3

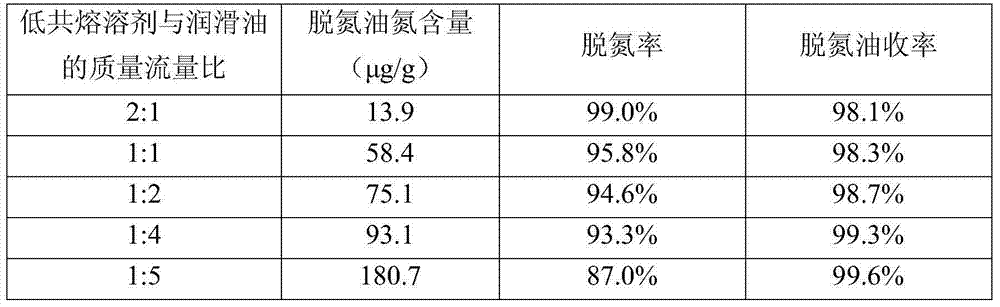

[0052] Lubricating oil base oil (nitrogen content: 1390 μg / g) and choline chloride / phenylpropionic acid deep eutectic solvent (the molar ratio of choline chloride and phenylpropionic acid is 1:1, the freezing point is lower than 25 ℃) in Three-stage countercurrent extraction was carried out in a packed column at 40°C. The raffinate oil is collected, washed with water and dried to obtain denitrogenated oil. By changing the mass flow ratio of deep eutectic solvent and lubricating oil, different denitrification rates and denitrification oil yields were obtained (Table 1). The extract was back-extracted with n-heptane at 50°C to remove nitrogen-containing compounds, and then evaporated to remove the residual n-heptane to obtain a regenerated choline chloride / phenylpropionic acid deep eutectic solvent.

[0053] Table 1 Choline chloride / phenylpropionic acid deep eutectic solvent three-stage countercurrent extraction to remove nitrogen-containing compounds in lubricating oil (nitrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freezing point | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com