Synthetic method for disulfide diisopropyl xanthate

A technology of diisopropyl xanthate disulfide and a synthesis method is applied in the field of chemistry, can solve the problems of a large amount of waste water containing salt and organic matter, cannot meet industrial production, low product yield and purity, etc., and achieves stable reaction. , easy to control, the effect of improving yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

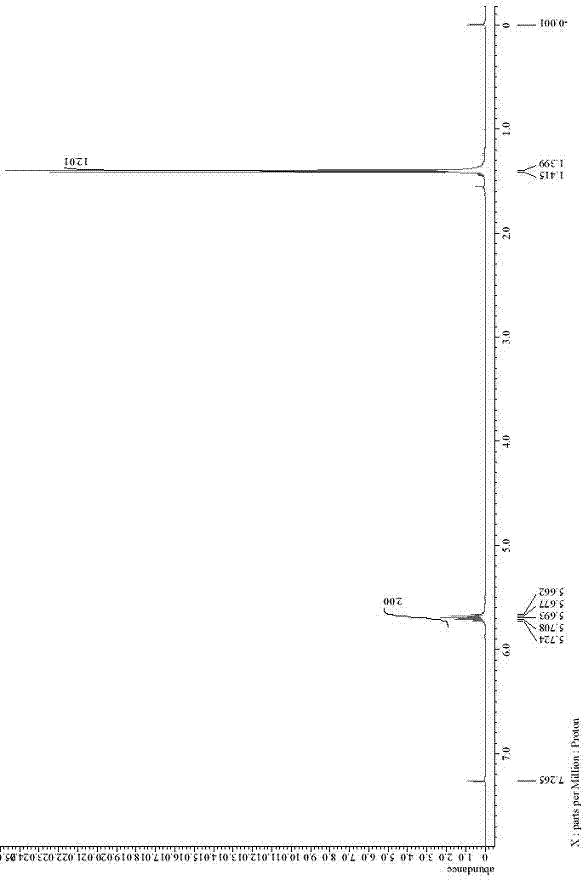

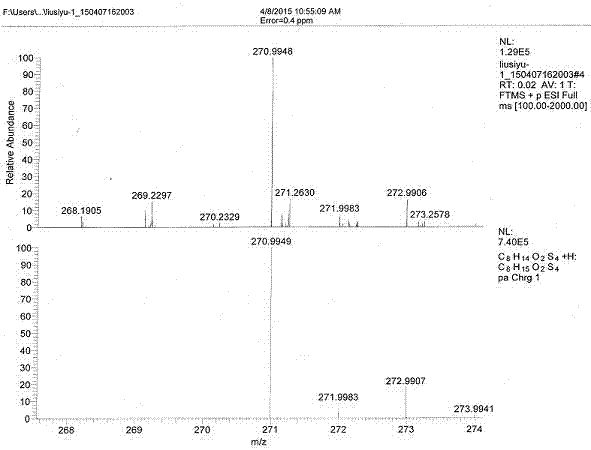

Image

Examples

Embodiment 1

[0033] Example 1 The synthetic method of diisopropyl xanthate disulfide comprises the following steps:

[0034] ⑴Synthesis of alkali metal alkoxide:

[0035] Using isopropanol (60.06g, 1.0mol) as the starting material, tetrahydrofuran (180.18 g) was added as the reaction solvent, and alkali metal hydroxide (30.03g, 0.75mol) was added at room temperature, and then the temperature was raised to 65°C for Reflux the reaction, cool down to room temperature after 0.5h, and obtain the alkali metal alkoxide reaction solution.

[0036] Wherein: the weight of tetrahydrofuran is 3 times of the weight of isopropanol; the weight of alkali metal hydroxide is 0.5 times of the weight of isopropanol.

[0037] The alkali metal hydroxide is sodium hydroxide.

[0038] ⑵ Synthesis of xanthate intermediates:

[0039] Using the water seal pressure method, slowly add carbon disulfide dropwise to the alkali metal alkoxide reaction solution at -5°C, and stir for 8 hours to obtain the xanthate ...

Embodiment 2

[0050] Example 2 The synthetic method of diisopropyl xanthate disulfide comprises the following steps:

[0051] ⑴Synthesis of alkali metal alkoxide:

[0052]Using isopropanol (60.06g, 1.0mol) as the starting material, tetrahydrofuran (180.18 g) was added as the reaction solvent, and alkali metal hydroxide (30.03g, 0.75mol) was added at room temperature, and then the temperature was raised to 60°C for Reflux the reaction, cool down to room temperature after 2h, and obtain the alkali metal alkoxide reaction solution.

[0053] Wherein: the weight of tetrahydrofuran is 3 times of the weight of isopropanol; the weight of alkali metal hydroxide is 0.5 times of the weight of isopropanol.

[0054] The alkali metal hydroxide is sodium hydroxide.

[0055] ⑵ Synthesis of xanthate intermediates:

[0056] Using the water seal pressure method, at 5°C, slowly add carbon disulfide dropwise into the alkali metal alkoxide reaction solution, and stir for 10 hours to obtain the xanthate ...

Embodiment 3

[0067] Example 3 The synthetic method of diisopropyl xanthate disulfide comprises the following steps:

[0068] ⑴Synthesis of alkali metal alkoxide:

[0069] With isopropanol (60.06g, 1.0mol) as the starting material, tetrahydrofuran (360.36 g) was added as the reaction solvent, alkali metal hydroxide was added at room temperature, and then the temperature was raised to 70°C for reflux reaction, and the temperature was lowered to At room temperature, the alkali metal alkoxide reaction liquid is obtained.

[0070] Wherein: the weight of tetrahydrofuran is 6 times of the weight of isopropanol; the weight of alkali metal hydroxide is 0.6 times of the weight of isopropanol.

[0071] The alkali metal hydroxide is sodium hydroxide.

[0072] ⑵ Synthesis of xanthate intermediates:

[0073] Using the water seal pressure method, at 0°C, slowly add carbon disulfide dropwise into the alkali metal alkoxide reaction solution, and stir for 9 hours to obtain the xanthate intermediate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com