Process for extracting and preparing high-purity raffinose from degreased wheat germ

A raffinose, high-purity technology, applied in the field of chemical engineering, can solve the problems of low extraction rate, limited industrial scale and efficiency, and prolonged crystallization time, and achieve the effect of simple and reliable process, convenient parameters, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (1) Weigh 200 g of defatted wheat germ (wherein the mass percentage of raffinose is 4.6%), and fill it into a percolation column (Φ4.0×50 cm) by wet method. Soak at a constant temperature of ℃ for 30 minutes to make it fully swell, open the outlet valve of the percolation column, and at the same time continuously add 80% ethanol aqueous solution from the top of the column, control the flow rate at 18-20mL / min, until the volume of the percolation liquid collected is 1371mL.

[0063] Weigh 230g of defatted wheat germ, and after wet packing evenly, its accumulation volume is 592mL, and other conditions are the same as above, and the volume of collected percolate is 1948mL.

[0064] Weigh 150g of defatted wheat germ, and after wet filling evenly, its accumulation volume is 355mL, and other conditions are the same as above, and the volume of collected percolate is 1066mL.

[0065] The above three groups of percolation liquids were combined as the raw material liquid for subs...

Embodiment 2

[0072] Take 500 mL of the extract in (1), and the operation method of (2) is the same as in Example 1. After analysis, the purity of the raffinose in the water phase is 28.7%, and the solid content concentration is 100.7 mg / mL.

[0073] (3) with 5wt% Na 2 SO 4 As extreme water, the conditions of electrodialysis are: voltage 25V, flow rate of each material 15L / h. After 2.5 hours of electrodialysis desalination, the conductivity of the desalination chamber decreased from the initial 992 μS / cm to 108 μS / cm.

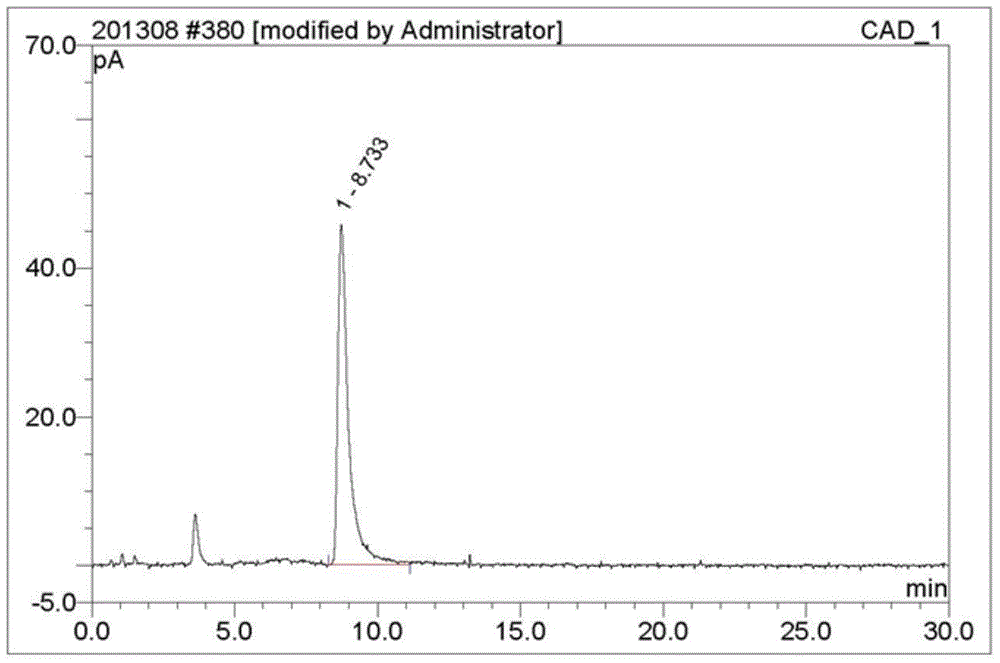

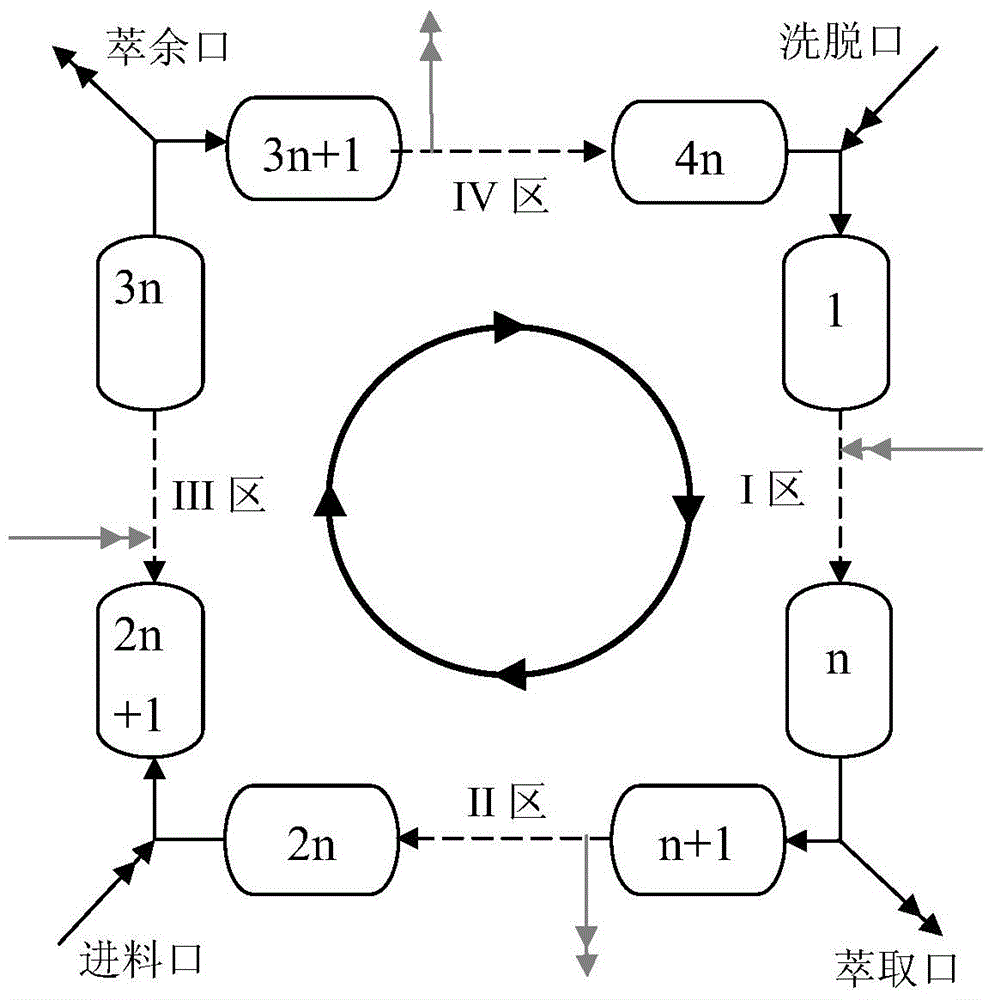

[0074] (4) Simulated moving bed separation: The simulated moving bed device is composed of 8 pieces of 25cm*0.46cm stainless steel filled with sodium-type strong ion exchange resins of 200-400 mesh and a cross-linking degree of 4% in series. The mouth is passed into the simulated moving bed device at a flow rate of 0.1mL / min, and the flow rate of each zone is: flow rate of zone I (0.75), flow rate of zone II (0.47), flow rate of zone III (0.51), flow rate of zone IV (0.5) ...

Embodiment 3

[0077] (1), (2) operation method is the same as embodiment 1.

[0078] (3) with 5wt% Na 2 SO 4 As extreme water, the conditions of electrodialysis are: voltage 25V, flow rate of each material 15L / h. After 2.5 hours of electrodialysis desalination, the conductivity of the desalination chamber decreased from the initial 1017 μS / cm to 115 μS / cm.

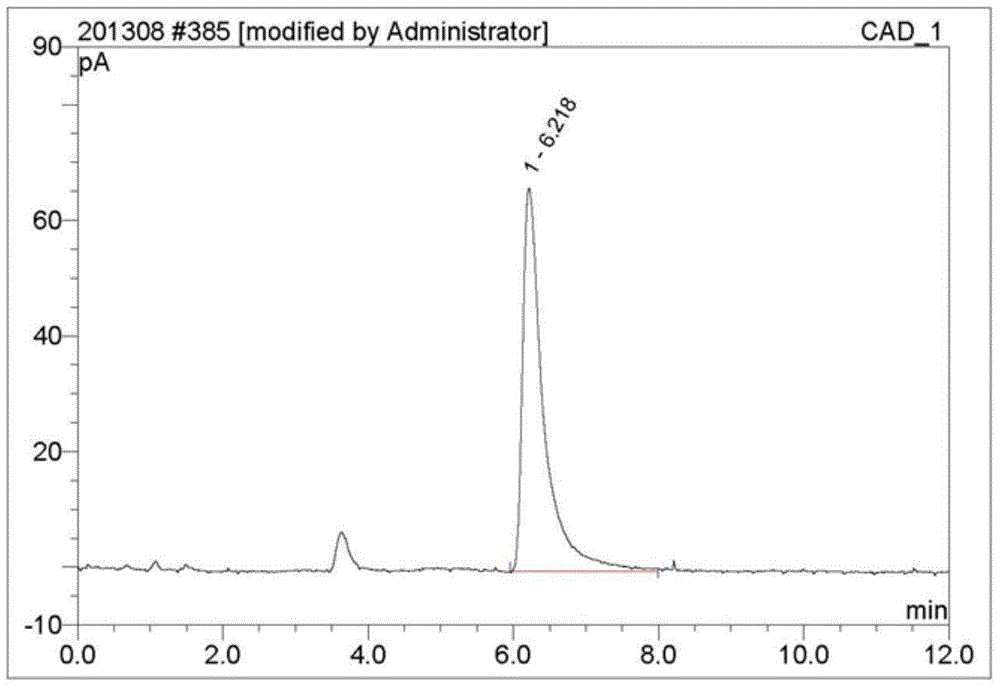

[0079] (4) Simulated moving bed separation: The simulated moving bed device is composed of 8 pieces of 25cm*0.46cm stainless steel filled with calcium-type strong ion exchange resins of 100-200 mesh and a cross-linking degree of 2% in series. The mouth is passed into the simulated moving bed device at a flow rate of 0.1mL / min, and the flow rate of each zone is: flow rate of zone I (0.75), flow rate of zone II (0.47), flow rate of zone III (0.51), flow rate of zone IV (0.5) . The switching time is 60s, and the separation temperature is 65°C. The raffinose-containing raffinose phase obtained from the raffinate port has a purity of 91...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com