Material capable of emitting near-infrared light by virtue of conversion of ultraviolet light as well as preparation method and application thereof

A near-infrared light and ultraviolet light technology, applied in luminescent materials, photovoltaic power generation, chemical instruments and methods, etc., can solve problems such as unreported, achieve the effect of easy product, improve photoelectric conversion efficiency, and strong absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

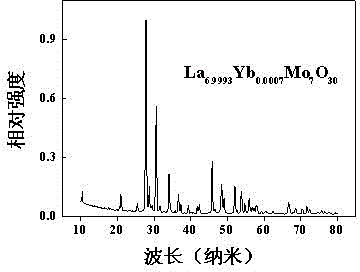

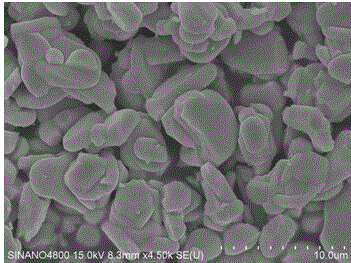

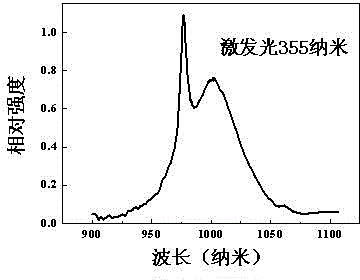

[0044] Embodiment 1: adopt high-temperature solid phase method to prepare La 6.9993 Yb 0.0007 Mo 7 o 30 , That is, mix various oxides or carbonates as raw materials according to the target composition stoichiometric ratio, and then synthesize them in an air atmosphere under normal pressure.

[0045] First, according to the chemical formula La 6.9993 Yb 0.0007 Mo 7 o 30 The stoichiometric ratio of each element in , respectively weigh lanthanum oxide La 2 o 3 : 2.28 g, ytterbium oxide Yb 2 o 3 : 0.00028 g, molybdenum oxide MoO 3 : 2.02 grams, ground in an agate mortar and mixed evenly, select the air atmosphere for the first calcining, the temperature is 300 ℃, the calcining time is 3 hours, cool to room temperature, take out the sample. Then, the samples from the previous step were fully ground and mixed again, and calcined in an air atmosphere at a temperature of 500°C for 4 hours, cooled to room temperature, and the samples were taken out. Finally, after fully gri...

Embodiment 2

[0050] Example 2: The high-temperature solid-phase method is also used to prepare the material La that can realize the conversion of ultraviolet light and emit near-infrared light 6.93 Yb 0.07 Mo 7 o 30 .

[0051] First, according to the chemical formula La 6.93 Yb 0.07 Mo 7 o 30 The stoichiometric ratio of each element in, respectively weighed lanthanum carbonate La 2 (CO 3 ) 3 ·8H 2 O: 3.18 g, ytterbium oxide Yb 2 o 3 : 0.028 g, molybdenum oxide MoO 3 : 2.02 grams, ground in an agate mortar and mixed evenly, select the air atmosphere for the first calcining, the temperature is 350 ℃, the calcining time is 5 hours, then cool to room temperature, take out the sample. The above samples were thoroughly ground and mixed evenly again, and calcined in an air atmosphere at a calcining temperature of 600°C for 12 hours, cooled to room temperature, and the samples were taken out. Finally, the sample from the previous step is fully ground and calcined in the air in a muff...

Embodiment 3

[0053] Embodiment 3: adopt high-temperature solid phase method to prepare La 6.65 Yb 0.35 Mo 7 o 30 .

[0054] First, according to the chemical formula La 6.65 Yb 0.35 Mo 7 o 30 The stoichiometric ratio of each element in , respectively weighed lanthanum hydroxide La(OH) 3 : 2.57 g, ytterbium oxide Yb 2 o 3 : 0.14 g, molybdenum oxide MoO 3 : 2.02 grams, ground in an agate mortar and mixed evenly, select the air atmosphere for the first calcination, the temperature is 400 ℃, the calcination time is 6 hours, then cool to room temperature, take out the sample. Thoroughly grind and mix again, calcined in air atmosphere, the calcined temperature is 550°C, the calcined time is 10 hours, cooled to room temperature, and the sample is taken out. Finally, it is fully ground and calcined in the air in a muffle furnace. The calcination temperature is 850°C, and the calcination time is 12 hours. After cooling to room temperature, it is taken out and fully ground to obtain La 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com