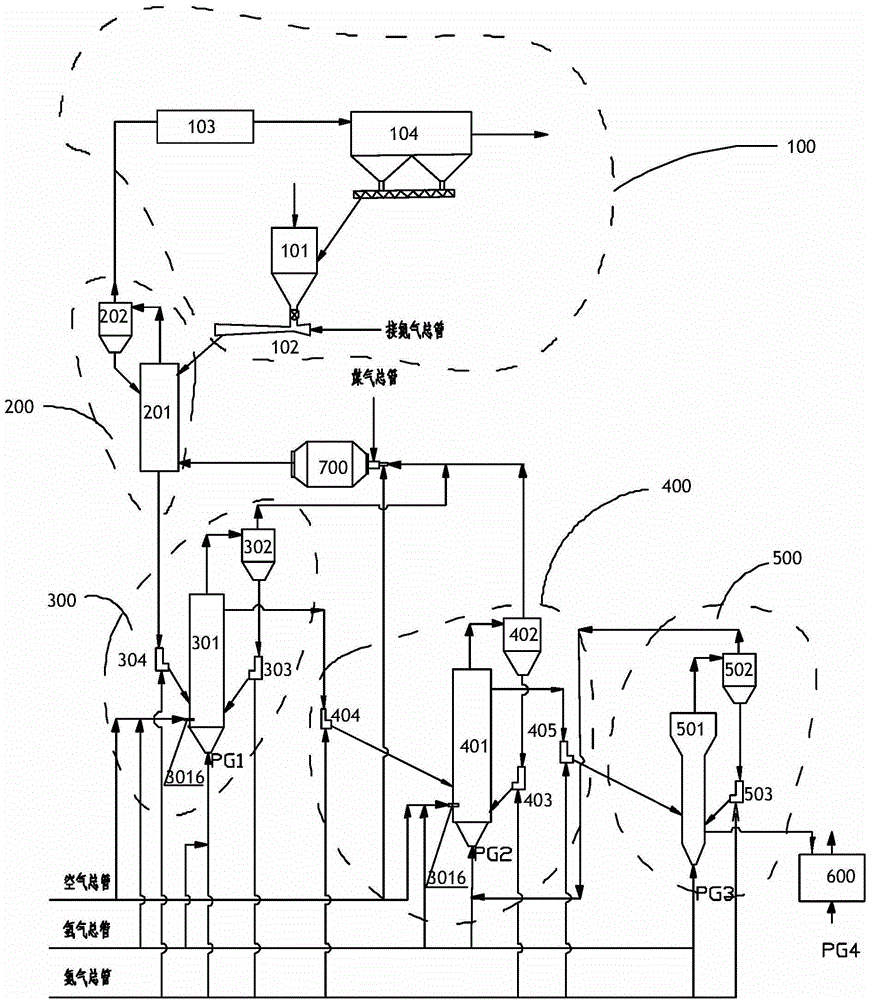

Equipment and method for preparing nanometer metal powder

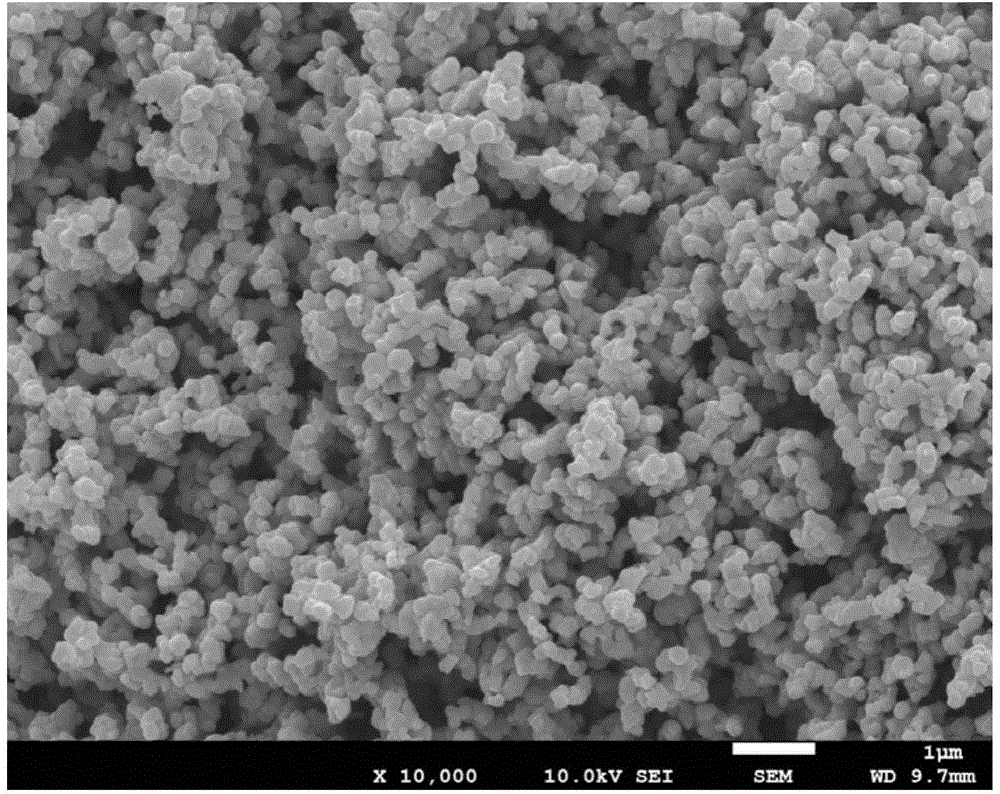

A nano-metal powder and equipment technology, which is applied in the field of equipment for preparing nano-metal powder, can solve the problems of product purity less than 90%, hindering the inward diffusion of hydrogen, and uneven particle size distribution, so as to achieve uniform and rapid vulcanization, prevent The effect of clogging the pipeline and agglomeration, high heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

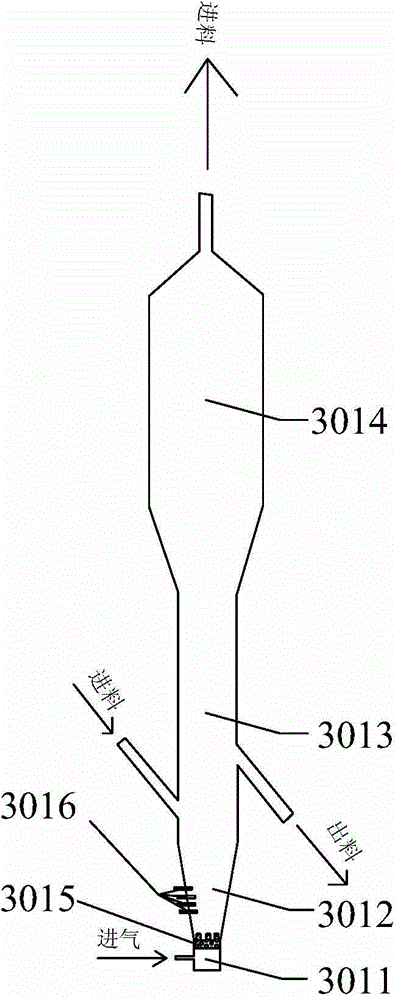

[0091] In the equipment for preparing nano-metal powders provided in Embodiment 2, the cone angles of the variable diameter sections of the first fluidized bed reduction furnace 301 and the second fluidized bed reduction furnace 401 are 1-30°, for example, 3° , 8°, 13°, 16°, 19°, 23°, 26°, etc., preferably 3-20°, more preferably 10°;

[0092] The gas distribution plate (3015, 4015) is an orifice distributor or a hood distribution plate; the opening rate of the gas distribution plate (3015, 4015) is 0.1-3%, preferably 0.1-1%; the gas The opening direction of the distribution plate (3015, 4015) is along the tangential direction of the circumference, so that the particles can be fluidized in a rotating manner.

[0093] The airflow conveying and feeding method preferably adopted in the present invention can prevent the nano particles from clogging pipelines, extrusion deformation and agglomeration, and is beneficial to obtain high-purity, low-density and uniform nano-metal powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com