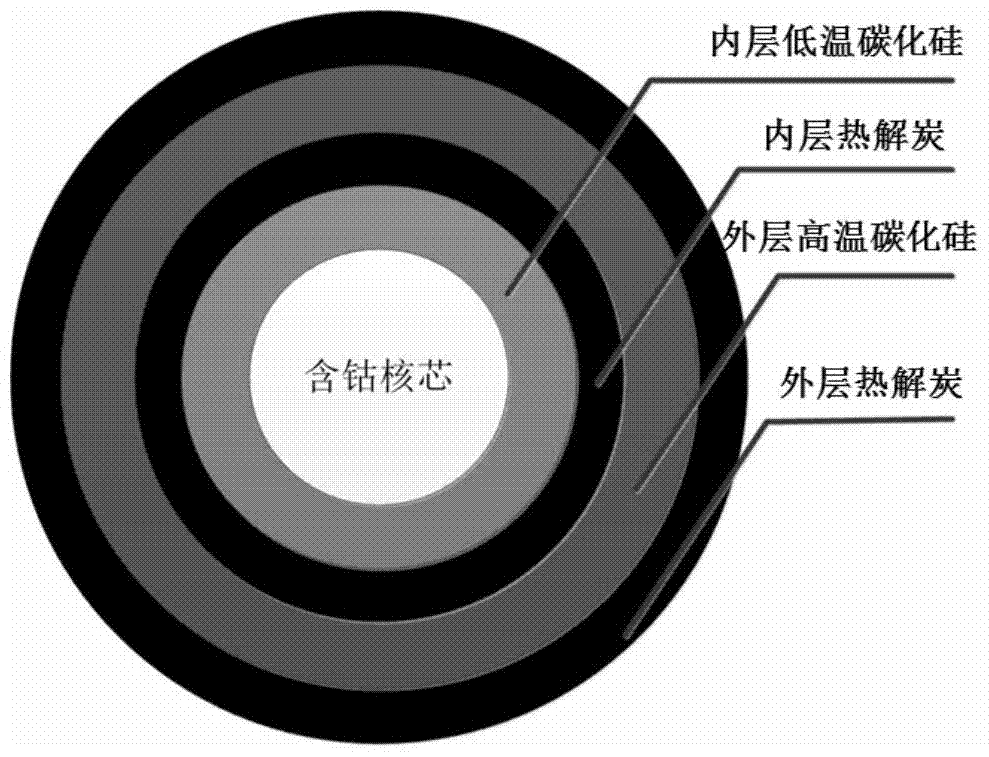

Cobalt-containing coated particles and preparation method thereof

A coating particle and coating technology is applied in the field of traced cobalt-containing coated particles and the preparation thereof, which can solve the problems of difficult operation of the distinguishing method, and achieve the effects of low cost, industrialized mass production, and convenient process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

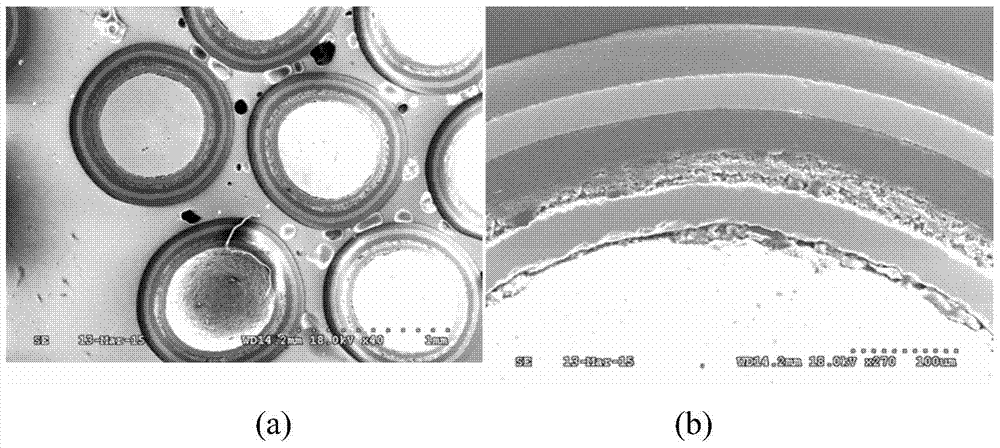

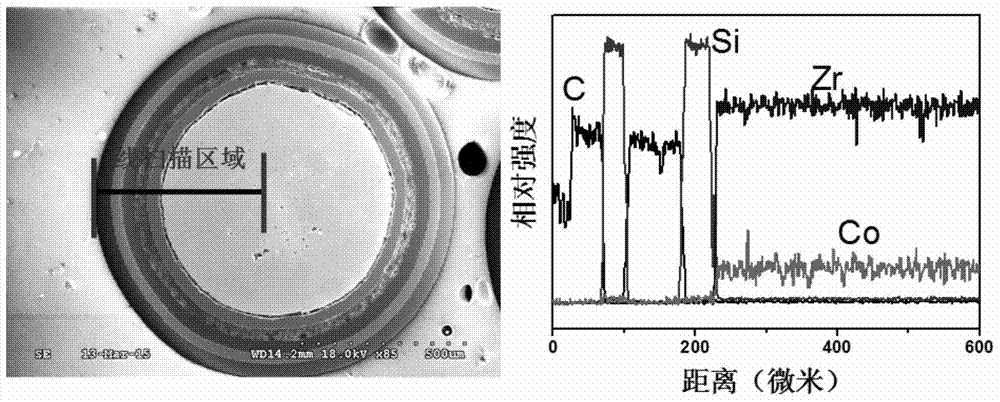

[0039] The fluidized bed reactor was heated to 1100 °C under an argon atmosphere; with Ar and H 2 The mixed gas is fluidizing gas, H 2 The flow rate of Ar is 6L / min, the flow rate of Ar is 1.0L / min, 40g ZrO 2 - CoO (based on the total mass of the particles, the mass fraction of CoO is 3%) particles are put into the fluidized bed for fluidization in the fluidized bed reaction zone at 1100° C., and the average diameter of the particles is 600 μm.

[0040] Methyltrichlorosilane steam, constant temperature at 35 °C, when the fluidized bed reaction zone continues to heat up to 1430 °C, methyl trichlorosilane steam is introduced, H 2 is the carrier gas, the flow rate of the carrier gas is 0.6L / min, and the reaction time is 2h to obtain a low-temperature silicon carbide layer. Lower the temperature to 1150°C, adjust the flow rate of Ar to 4.0L / min, the flow rate of acetylene to 5L / min, and the reaction time to 40s to obtain a loose pyrolytic carbon layer. The temperature of the fl...

Embodiment 2

[0045] The fluidized bed reactor was heated to 1100 °C under an argon atmosphere; with Ar and H 2 The mixed gas is fluidizing gas, H 2 The flow rate of Ar is 8L / min, the flow rate of Ar is 0.6L / min, 40g ZrO 2 -CoO (based on the total mass of the particles, the mass fraction of CoO is 6%) particles are placed in a fluidized bed at 1100° C. for fluidization, and the average diameter of the particles is 800 μm.

[0046] Methyltrichlorosilane is made into steam at 35°C with a constant temperature water bath, and the temperature of the fluidized bed is continuously raised to 1430°C to feed methyltrichlorosilane steam, H 2 is the carrier gas, the flow rate of the carrier gas is 0.6L / min, and the reaction time is 3h to obtain a low-temperature silicon carbide layer. Cool the fluidized bed to 1150°C, adjust the Ar flow rate to 4.0 L / min, the acetylene flow rate to 5 L / min, and the reaction time to 40 s to obtain a loose pyrolytic carbon layer. Adjust the gas flow into the fluidized...

Embodiment 3

[0049] The fluidized bed reactor was heated to 1100 °C under an argon atmosphere; with Ar and H 2 The mixed gas is fluidizing gas, H 2 The flow rate of Ar is 6L / min, the flow rate of Ar is 1.0L / min, 40g ZrO 2 - CoO (based on the total mass of the particles, the mass fraction of CoO is 8%) particles are placed in a fluidized bed at 1100° C. for fluidization, and the average diameter of the particles is 600 μm.

[0050] Dimethyldichlorosilane vapor is kept at 30°C with a constant temperature water bath, and the temperature is continuously raised to 1380°C to feed dimethyldichlorosilane vapor, H 2 is the carrier gas, the flow rate of the carrier gas is 0.4L / min, and the reaction time is 2h to obtain a low-temperature silicon carbide layer. The temperature of the fluidized bed reaction zone was raised to 1350°C, the flow rate of Ar was adjusted to 4.0L / min, the flow rate of propylene was 2.0L / min, and the reaction time was 160s to obtain an inner dense pyrolytic carbon layer. R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com