Nanocrystal particle, process for synthesizing the same, and device comprising the same

A technology of nanocrystal particles and nanocrystals, applied in nanotechnology, nanooptics, nanotechnology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0139] Reference Example 1: Preparation of InP Core

[0140] Put 0.2 millimoles (mmol) (0.058 grams (g)) of indium acetate, 0.6 mmol (0.15 g) of palmitic acid, and 10 milliliters (mL) of 1-octadecene in a flask, and in a vacuum state at 120 ° C After heating for one hour, the atmosphere in the flask was replaced with N 2 After replacement, heat to 280°C. Then, a mixed solution of 0.1 mmol (29 microliters (μL)) of tris(trimethylsilyl)phosphine (“TMS3P”) and 0.5 mL of trioctylphosphine (“TOP”) was quickly injected thereinto, and the reaction proceeded 20 minutes. The reaction mixture was then rapidly cooled to room temperature, and acetone was added to it to precipitate the nanocrystals, which were then separated by centrifugation and redispersed in toluene. The first UV absorption maximum wavelength of the thus prepared InP core nanocrystal is 560nm-590nm.

example 2

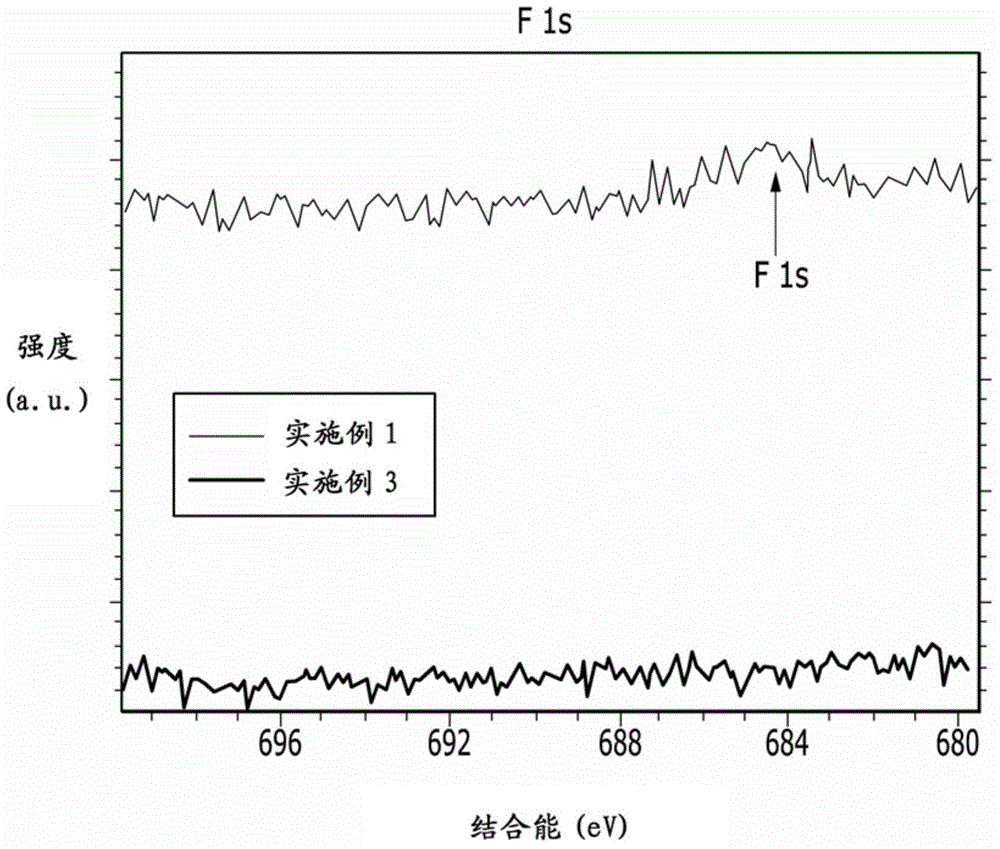

[0141] Reference Example 2: Preparation of InP core including boron and fluorine

[0142] 0.2 mmol (0.058 g) of indium acetate, 0.6 mmol (0.15 g) of palmitic acid and 10 mL of 1-octadecene were placed in a flask, and heated at 120° C. for one hour under vacuum, and then the atmosphere in the flask was replaced with N 2 replacement. The reaction solution was heated to 280 °C, and 0.7 mmol of ethoxyethane-trifluoroborane (BF 3 .Et 2O). Subsequently, a mixed solution of 0.1 mmol of tris(trimethylsilyl)phosphine (“TMS3P”) and 0.5 mL of trioctylphosphine (“TOP”) was rapidly injected thereto. The reaction was carried out for 20 minutes. The reaction mixture was then rapidly cooled to room temperature, and acetone was added to it to precipitate the nanocrystals, which were then separated by centrifugation and dispersed in toluene. The InP semiconductor nanocrystal thus prepared had a light emission peak similar to that of the nanocrystal of Reference Example 1. The results of ...

Embodiment 1

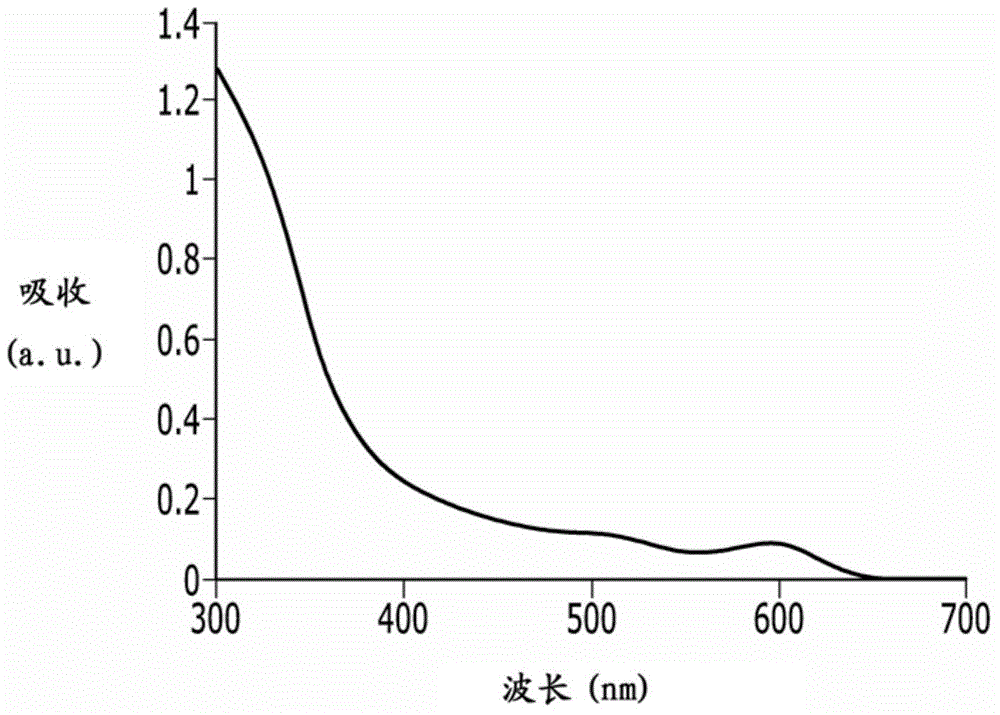

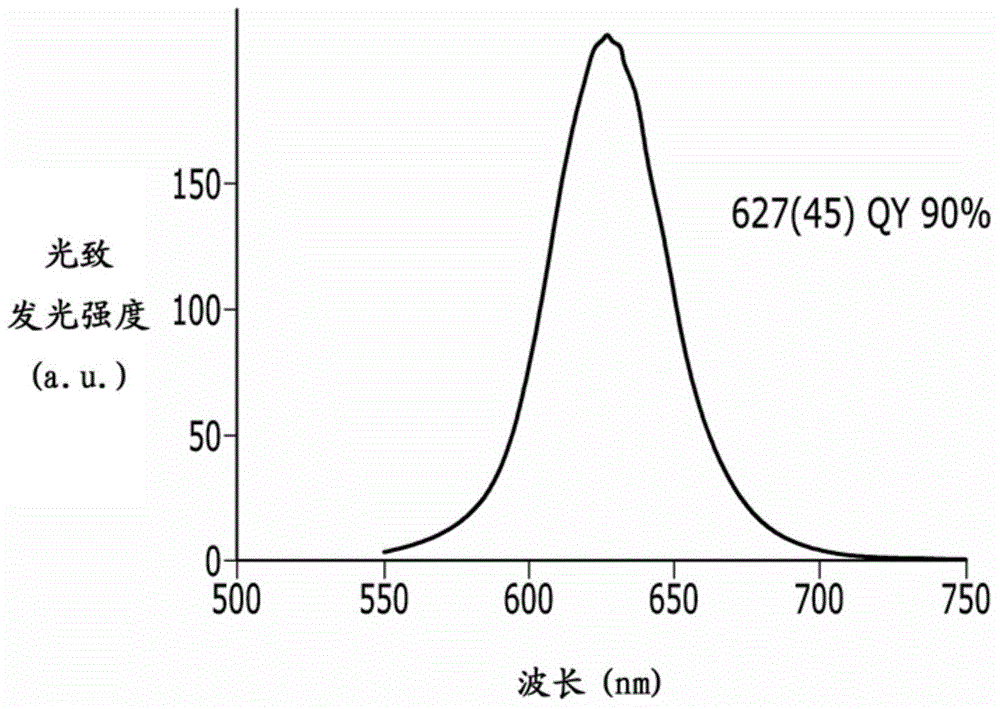

[0143] Embodiment 1: Preparation of InP / BF_ZnS nano crystal particles

[0144] 1.2mmol (0.224g) of zinc acetate, 2.4mmol (0.757g) of oleic acid and 10mL of trioctylamine were placed in a flask, and heated at 120°C for one hour under vacuum, and then the atmosphere in the flask was replaced with N 2 replacement. Then, the reaction solution was heated to 280°C, and borane dimethylamine (BH 3 NMe 2 H) 0.07 mL of a 0.2 M toluene solution, and then 1 mL of the InP core solution prepared in Reference Example 1 was added thereto (OD = optical density of first exciton absorption, OD: 0.3, measured when diluted 100 times with toluene) And then add 2.4mmol S-TOP. After injecting it quickly with a mixture of 0.14 mmol HF (6 μL of aqueous solution) and 1.5 mL of trioctylamine ("TOA"), the reaction was carried out for 2 hours. The reaction mixture was then rapidly cooled to room temperature, and ethanol was added thereto to precipitate the nanocrystals, which were then separated by cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com