Treatment method of gold and silver pyrite

A treatment method and technology of pyrite, which is applied in the field of gold-silver pyrite treatment, can solve problems such as incapable enterprises, high investment costs, and no application manufacturers, etc., and achieve reduced processing scale, short process flow, and equipment efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

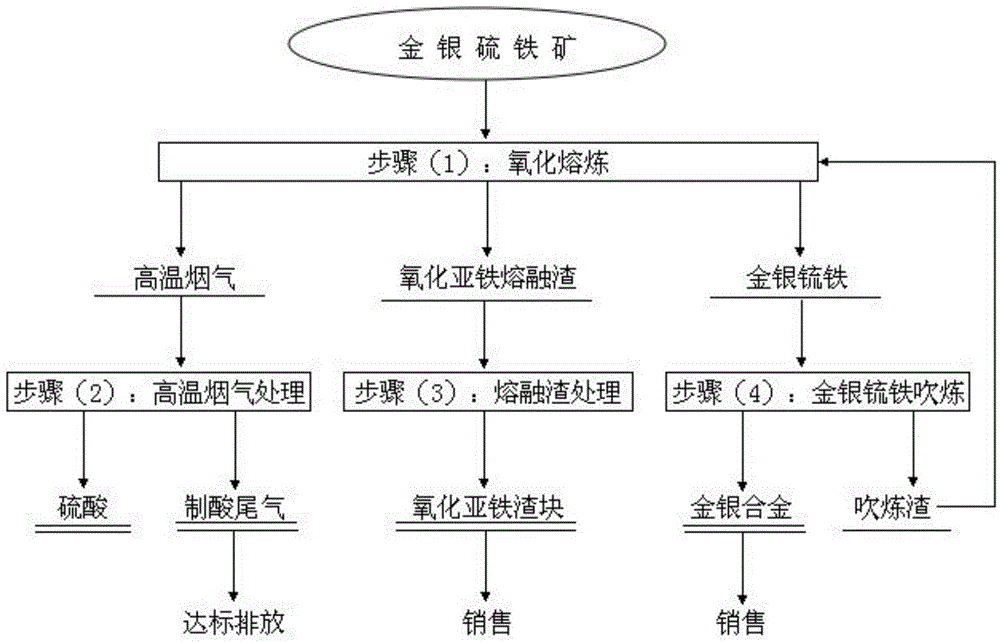

[0030] A processing method of gold-silver pyrite, such as figure 1 shown, including the following steps:

[0031] (1) Oxidation smelting: the gold-silver pyrite containing mass percentages of 0.0001% gold, 0.005% silver, 30% iron and 32% sulfur is added to the Australian mine with an inner diameter of 4 meters at a rate of 12 tons / hour. Smelt furnace, while injecting O at a rate of 30,000 standard cubic meters per hour 2 Air with a volume percentage of 21% is oxidized and smelted at 1200°C to obtain 29,000 standard cubic meters per hour containing SO 2 High-temperature flue gas with a volume percentage of 7%, 7.7 tons / hour of ferrous oxide molten slag, and 0.6 tons / hour of gold-silver matte iron with mass percentages of 0.002% gold and 0.1% silver respectively;

[0032] (2) High-temperature flue gas treatment: use the waste heat boiler to recover the waste heat from the high-temperature flue gas obtained in step (1), and obtain 7 tons / hour of superheated steam with a tempera...

Embodiment 2

[0036] A processing method of gold-silver pyrite, such as figure 1 shown, including the following steps:

[0037] (1) Oxidation smelting: the gold-silver pyrite containing mass percentages of 0.001% gold, 0.025% silver, 40% iron, and 42% sulfur is added to the hearth area of 60 square meters at a rate of 20 tons / hour. Bottom-blown furnace, while injecting O-containing gas at a rate of 36,000 2 Oxygen-enriched air with a volume percentage of 32% is oxidized and smelted at 1300°C to obtain 33,000 standard cubic meters per hour containing SO 2 High-temperature flue gas with a volume percentage of 16%, 13.4 tons / hour of ferrous oxide molten slag, and 1.08 tons / hour of gold and silver matte iron with mass percentages of 0.018% gold and 0.45% silver respectively;

[0038] (2) High-temperature flue gas treatment: use the waste heat boiler to recover the waste heat from the high-temperature flue gas obtained in step (1), and obtain 7 tons / hour of superheated steam with a temperatu...

Embodiment 3

[0042] A processing method of gold-silver pyrite, such as figure 1 shown, including the following steps:

[0043] (1) Oxidation smelting: the gold-silver pyrite containing mass percentages of 0.003% gold, 0.05% silver, 48% iron, and 52% sulfur is added to the moxa with an inner diameter of 5.4 meters at a speed of 30 tons / hour. Sa furnace, at the same time at the speed of 50000 standard cubic meters per hour into the O-containing 2 Oxygen-enriched air with a mass percentage of 48% is oxidized and smelted at 1400°C to obtain 47,000 standard cubic meters per hour containing SO 2 High-temperature flue gas with a mass percentage of 20%, 17.2 tons / hour of ferrous oxide molten slag, and 1.47 tons / hour of gold and silver matte iron with a mass percentage of 0.06% gold and 1.0% silver respectively;

[0044] (2) High-temperature flue gas treatment: use the waste heat boiler to recover the waste heat from the high-temperature flue gas obtained in step (1), and obtain 9 tons / hour of su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com