A kind of multifunctional viscose fiber and preparation method thereof

A viscose fiber, multi-functional technology, applied in the field of multi-functional viscose fiber and its preparation, can solve the problems of inconspicuous radiation protection, inability to solve the agglomeration phenomenon well, affecting the effect of nano silver particles, etc. Infrared effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the porous cellulose comprises the following steps: A), hydrolyzing biomass resources in acid to obtain lignocellulose, and the biomass resources include one or more of plants and agricultural and forestry wastes; B) ), treating the lignocellulose to obtain porous cellulose, the treatment comprising acid treatment, salt treatment or organic solvent treatment. In the present invention, the hydrolysis temperature is preferably 90°C to 180°C, more preferably 120°C to 150°C. In the present invention, the hydrolysis time is preferably 2h-10h, more preferably 2h-8h, most preferably 3h-6h. In the present invention, the hydrolyzed acid is preferably one or more of sulfuric acid, nitric acid, hydrochloric acid, formic acid, sulfurous acid, phosphoric acid and acetic acid, more preferably sulfuric acid, nitric acid, hydrochloric acid, phosphoric acid or acetic acid, most preferably sulfuric acid, nitric acid or hydrochloric acid. In the present inventi...

Embodiment 1

[0106] At 120° C., hydrolyzing corncobs in sulfuric acid for 30 minutes to obtain lignocellulose, the mass of the sulfuric acid being 3% of the mass of the corncobs;

[0107] At 70°C, the lignocellulose was subjected to an acidic sulfite treatment for 1 hour to obtain porous cellulose, the pH value during the acidic sulfite treatment was 1, the acid was sulfuric acid, and the sulfite was Magnesium sulfite, the quality of the sulfuric acid is 4% of the lignocellulose quality, and the liquid-solid ratio is 2:1;

[0108] The porous cellulose is bleached with hydrogen peroxide, the mass of the hydrogen peroxide is 5% of the mass of the porous cellulose, the bleaching temperature of the hydrogen peroxide bleach is 100° C., and the bleaching time is 5 hours.

[0109] Stirring the bleached porous cellulose and nickel chloride at 20°C for 2 hours for activation treatment, the mass ratio of nickel chloride and porous cellulose is 0.1:1; Drying under low temperature, obtain the product...

Embodiment 2

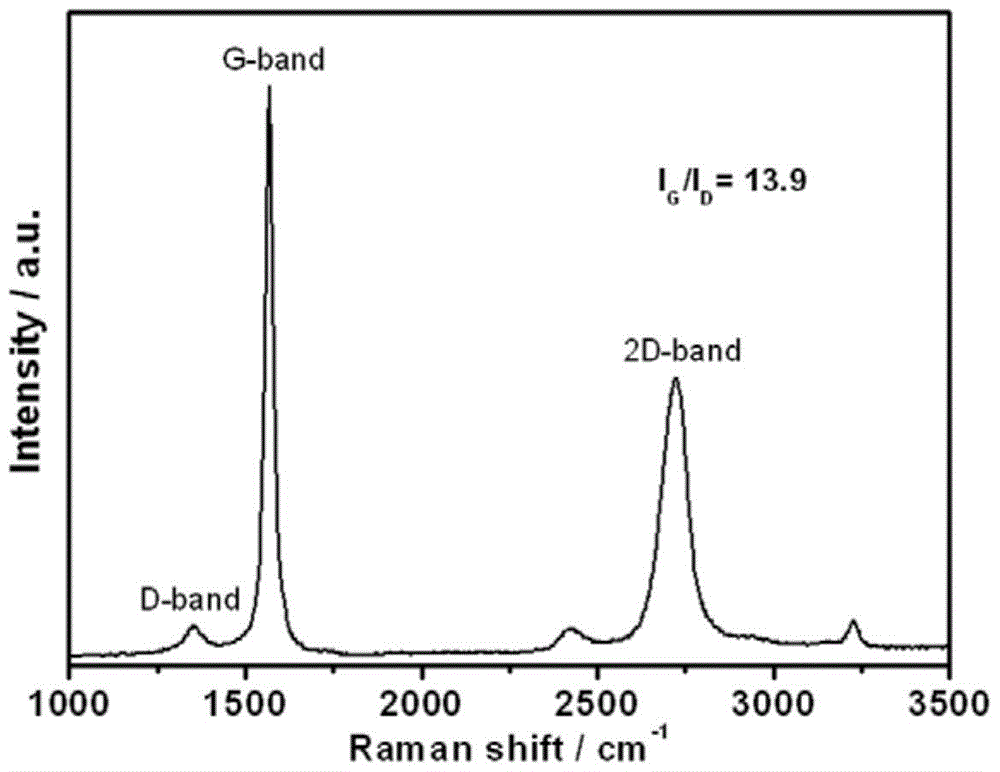

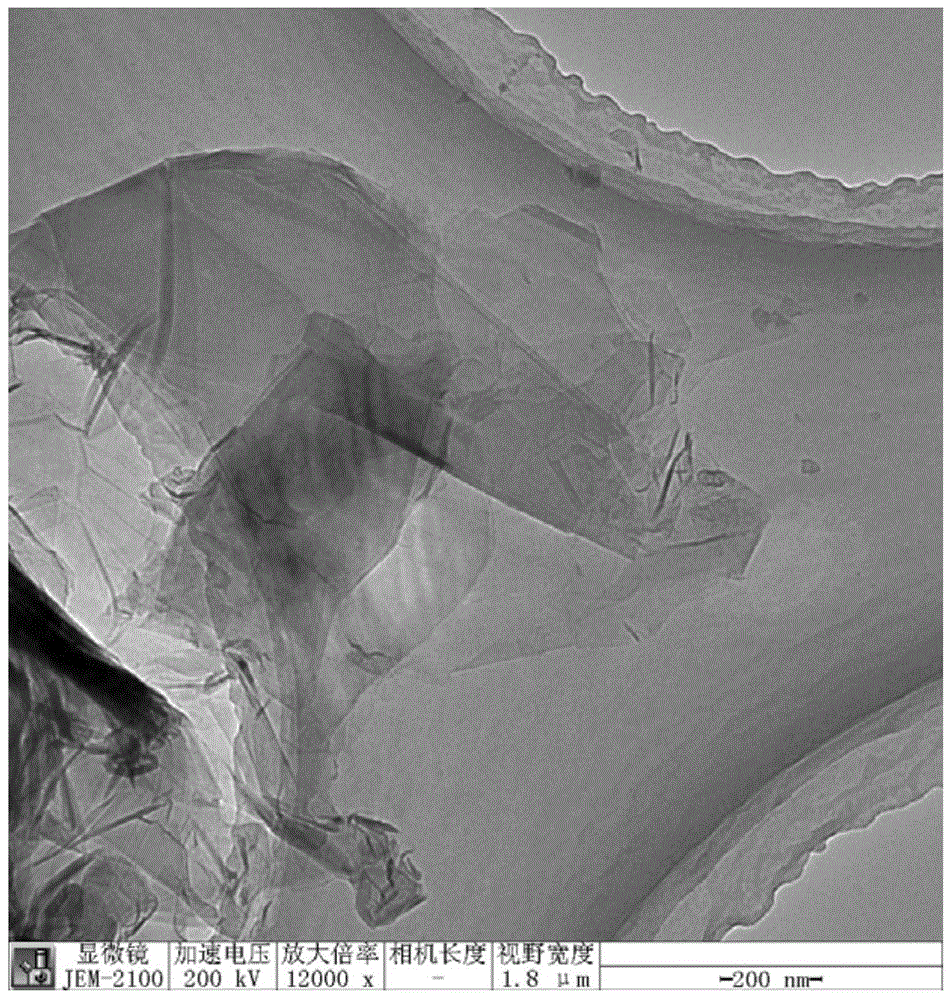

[0114] The graphene prepared by 1g embodiment 1 is ultrasonically dispersed in 100g water for 100min, centrifuged at a speed of 2000rpm for 5min, and after taking the supernatant, add SDS to obtain a graphene colloidal solution; the graphene colloidal solution is ultrasonically dispersed in water for 100min again to obtain graphite vinyl colloid solution;

[0115] Ultrasonic disperse the above-mentioned graphene colloidal solution in water for 100 minutes again to obtain a graphene dispersion; add 0.02mol / L silver nitrate to the graphene dispersion under stirring conditions, and slowly add 0.2mol / L silver nitrate after stirring and dissolving in the dark. Sodium borohydride solution, reacted 100min at room temperature; Wherein, the mass ratio of silver nitrate and graphene is 1:10, and the mol ratio of sodium borohydride and silver nitrate is 10:1;

[0116] The reactant obtained after the reaction was ultrasonically treated for 30 min to obtain a graphene solution loaded with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com