Iron trioxide monocrystal nanotube/graphene composite electrode material and preparation method thereof

A composite technology of ferric oxide and graphene, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of volume change, electrode material cracking, fragmentation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Preparation of graphene

[0026] Under the conditions of cooling in an ice bath and stirring, add 69 mL of concentrated H 2 SO 4 Add 1.5 g NaNO to 3 (ground), to be NaNO 3 completely soluble in H 2 SO 4 After neutralization, 3.0 g of graphite was added into it while stirring. Then slowly add 9.0 g KMnO 4 , the addition rate was strictly controlled to ensure that the temperature was lower than 20 °C, then the ice bath was removed, and a water bath was used to keep the temperature at about 35 °C for 2 h. Slowly add 137 mL of deionized water under stirring, rapidly raise the temperature to 98 °C, and keep it in a 98 °C water bath for 15 minutes, then further dilute to 420 mL with 60 °C deionized water, and then add 11 mL of 30% hydrogen peroxide to reduce the remaining Potassium permanganate and manganese dioxide give a bright yellow system. Filter while hot, then wash once with hydrochloric acid solution with a volume ratio of 1:10, and wash with distilled wate...

Embodiment 2

[0033] 1) The preparation method of graphene is the same as step 1) in Example 1.

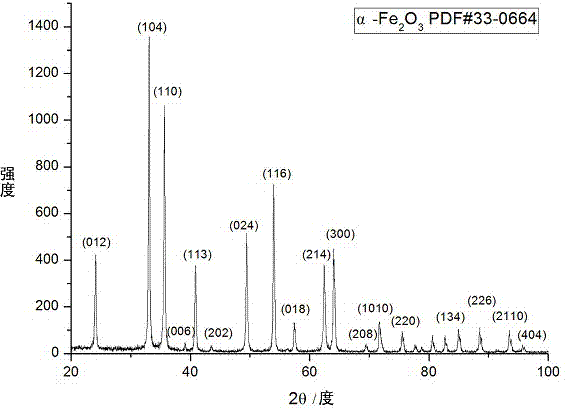

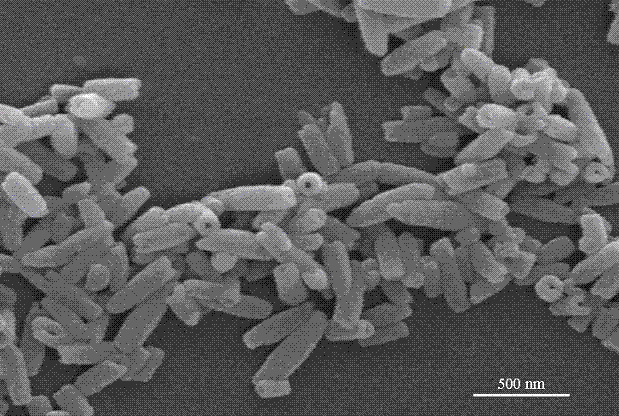

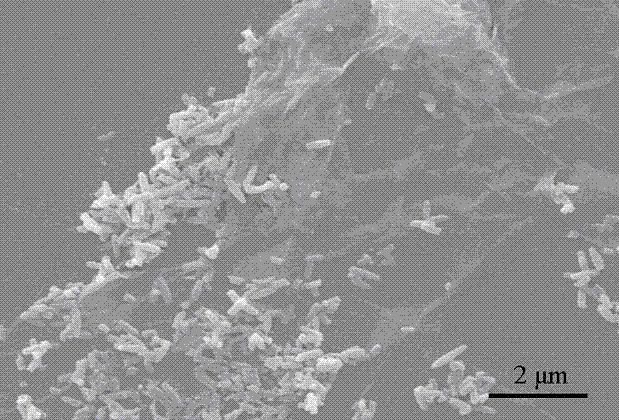

[0034] 2) α-Fe 2 o 3 Preparation of Single Crystal Nanotubes

[0035] with FeCl 3 ·6H 2 O solid and deionized water configuration concentration is 0.5 mol / L ferric chloride aqueous solution, with NH 4 h 2 PO 4 Solid and deionized water to prepare an aqueous ammonium dihydrogen phosphate solution with a concentration of 0.02 mol / L; transfer ferric chloride aqueous solution (10.0 mL) and ammonium dihydrogen phosphate aqueous solution (9.0 mL) to a 300 mL beaker, and then add Add 235 mL of deionized water into the beaker to form a mixed solution; quickly stir the mixed solution for 20-30 minutes to form a homogeneous solution; transfer the stirred homogeneous solution to a 100 mL stainless steel high-pressure tank with a polytetrafluoroethylene liner In the reaction kettle, the temperature was kept at 210 ℃ in an air flow oven for 50 h; centrifuged, washed with ethanol and deionized water s...

Embodiment 3

[0039] 1) The preparation method of graphene is the same as step 1) in Example 1.

[0040] 2) α-Fe 2 o 3 Preparation of Single Crystal Nanotubes

[0041] with FeCl 3 ·6H 2 O solid and deionized water configuration concentration is 0.5 mol / L ferric chloride aqueous solution, with NH 4 h 2 PO 4 Solid and deionized water to prepare an aqueous ammonium dihydrogen phosphate solution with a concentration of 0.02 mol / L; pipette aqueous ferric chloride (5.0 mL) and aqueous ammonium dihydrogen phosphate (4.5 mL) into a 200 mL beaker, and then add Add 113 mL of deionized water into the beaker to form a mixed solution; quickly stir the mixed solution for 20-30 minutes to form a homogeneous solution; transfer the stirred homogeneous solution to a 100 mL stainless steel high-pressure tank with a polytetrafluoroethylene liner In a reaction kettle, keep it in an air flow oven at 230 °C for 46 h; centrifuge, wash with ethanol and deionized water several times; dry the product in vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com