Silk fibroin anti-adhesion film and preparation method thereof

A silk fibroin and anti-adhesion film technology, applied in the field of medical materials, can solve the problems of insufficient hydrogel strength, lack of anti-adhesion film, and many chemical additives, and achieve good tissue compatibility and blood compatibility , reduce surgical complications, and reduce patient pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

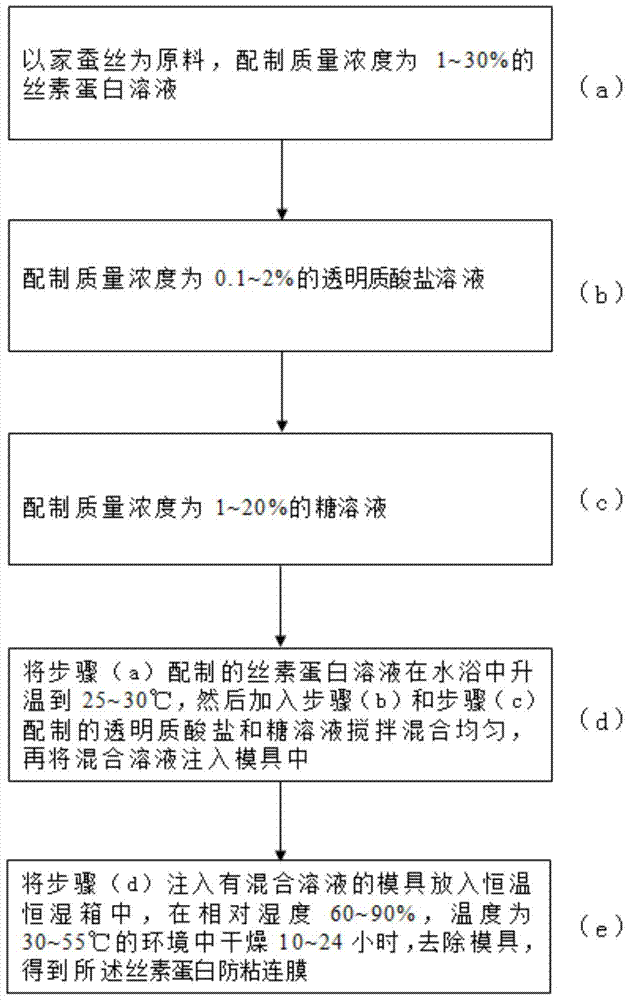

[0034] refer to figure 1 , as above the preparation method of silk fibroin anti-adhesion film comprises steps:

[0035] (a), using domestic silkworm silk as raw material, preparing a silk fibroin solution with a mass concentration of 1-30%;

[0036] (b) preparing a hyaluronate solution with a mass concentration of 0.1-2%;

[0037] (c), preparing a sugar solution with a mass concentration of 1 to 20%;

[0038] (d), heat up the silk fibroin solution prepared in step (a) to 25-35°C in a water bath, then add the hyaluronic acid salt and sugar solution prepared in step (b) and step (c) and stir to mix evenly, then Inject the mixed solution into the mold;

[0039] (e), put the mold injected with the mixed solution in step (d) into a constant temperature and humidity box, dry it for 10-24 hours in an environment with a relative humidity of 60-90% and a temperature of 30-55°C, and remove the mold. The silk fibroin anti-adhesion film is obtained.

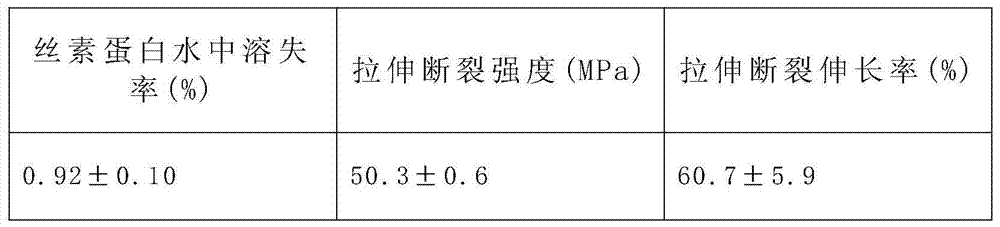

[0040] For the effect of anti-ad...

Embodiment 1

[0043] 1. First put 40 grams of Baichang silk into 2 liters of sodium bicarbonate with a mass concentration of 0.2 g / L and 1 g / L sodium dodecyl sulfate (SDS), and treat it at 98-100 ° C for 0.5 hours. Take it out and wash it thoroughly; then put it into 2 liters of sodium bicarbonate with a mass concentration of 0.2g / L and a mixed solution of 1g / L SDS again, treat it at 98-100°C for 0.5 hours, take it out and wash it fully; then put it into a 400mL mass concentration In the 3g / L papain solution, treat at 60°C for 1 hour to degumming the silk, take it out, wash it thoroughly and dry it to obtain pure silk fibroin fiber. Weigh 10g of pure silk fiber and dissolve it in 100mL of lithium bromide solution with a concentration of 9.3mol / L, and slowly stir and dissolve it at a temperature of 60±2°C to form a mixed solution of silk fibroin lithium bromide.

[0044] 2. Put the obtained silk fibroin lithium bromide mixed solution into a dialysis bag, dialyze with deionized water for 3 da...

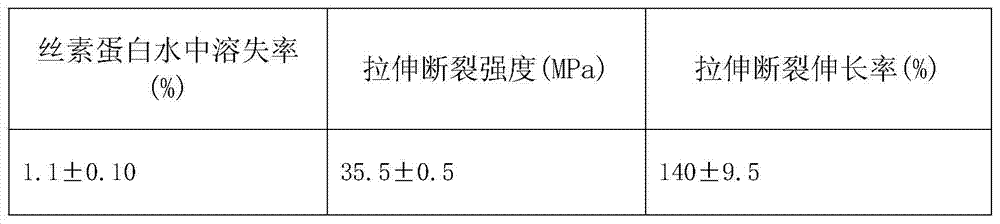

Embodiment 2

[0052] 1. Put 80 g of raw silk into 4 liters of 0.05% sodium carbonate aqueous solution, treat it at 98-100° C. for 2 hours, degumming the raw silk, take it out and wash it thoroughly, and degumming again to obtain pure silk fibroin. The dried pure silk fibroin is heated and dissolved with 1 L of lithium bromide solution with a concentration of 9.0 mol / L at a temperature of 60±5° C. to obtain a silk fibroin lithium bromide mixed solution.

[0053] 2. Put the obtained silk fibroin lithium bromide mixed solution into a dialysis bag, dialyze with deionized water for 3 days, remove impurities such as lithium bromide, and obtain pure silk fibroin solution; adjust the concentration of silk fibroin protein solution to 20g / L, store Store in a refrigerator at a temperature of 4-8°C for later use.

[0054] 3. Prepare a sodium hyaluronate solution with a mass percentage concentration of 0.5%, and a mannose solution with a mass percentage concentration of 12%, and store them in a refriger...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com