Hydrophobic inorganic porous membrane and preparation method thereof

An inorganic porous and hydrophobic technology, which can be used in separation methods, chemical instruments and methods, membrane technology, etc., and can solve problems such as sintering mismatch of inorganic materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

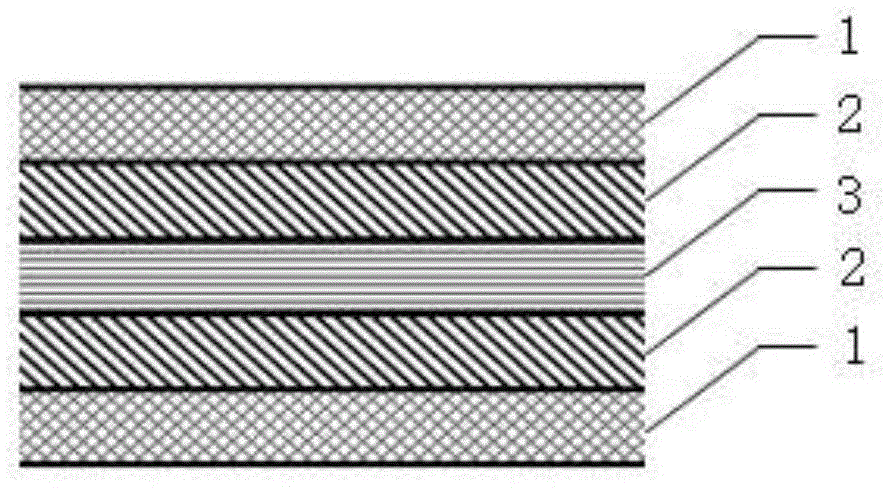

[0024] Weigh 70g of yttrium-stabilized zirconia (YSZ), add 3.5g of starch, and ball mill to obtain a support material powder. Weigh 15g of yttrium oxide, add 0.7g of starch, and then ball mill it evenly to obtain the film layer material powder. In addition, 0.15 g of yttrium oxide and 14.85 g of YSZ were weighed, 0.75 g of starch was added, and ball milled to obtain a transition layer material powder. The green body is made by tape casting, and the green body has a five-layer structure: yttrium oxide film layer, transition layer, YSZ support layer, transition layer, yttrium oxide film layer (the quality of each layer of yttrium oxide film layer is the same as that of each transition layer ,Such as figure 1 shown). It is then sintered in a high temperature furnace at 1100°C for 2 hours, and then cooled. When the temperature is higher than 600°C, the heating (or cooling) rate is 2.5°C / min; when the temperature is lower than 600°C, the heating (or cooling) rate is 4°C / min. Th...

Embodiment 2

[0027] Weighed 194g of zirconia, added 19.4g of polyvinyl alcohol (PVA, 10% by mass) and ball-milled to obtain support material powder. Weigh 2g of lanthanum oxide, add 0.2g of the above PVA, and then ball mill to obtain a film layer material powder. In addition, 2 g of zirconia and 2 g of lanthanum oxide were weighed, and 0.4 g of the above-mentioned PVA was added and ball-milled to obtain a transition layer material powder. The green body is made by slip casting method, and the green body has a five-layer structure: lanthanum oxide film layer, transition layer, zirconia support body layer, transition layer, lanthanum oxide film layer (each layer of lanthanum oxide film layer and the mass of each transition layer Same). Then sinter at 1200°C for 3 hours in a high-temperature furnace, and then cool to obtain a lanthanum oxide tubular film, wherein the temperature rise (or temperature drop) rate is 0.5°C / min when the temperature is higher than 600°C; Cooling) rate is 2.5°C / mi...

Embodiment 3

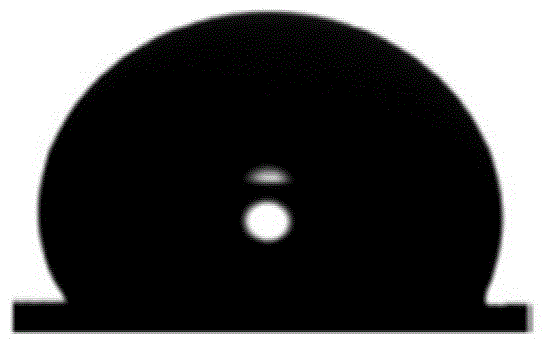

[0030] Weigh 80g of alumina, and ball mill it evenly to obtain support body material powder. Weigh 10 g of cerium oxide, and grind it evenly to obtain a film layer material powder. In addition, 4 g of cerium oxide and 6 g of aluminum oxide were weighed and ground uniformly to obtain transition layer material powder. The green body is made by extrusion molding, and the green body has a five-layer structure: a cerium oxide film layer, a transition layer, an alumina support layer, a transition layer, and a cerium oxide film layer. Then sinter in a high-temperature furnace at 1250°C for 2.5h, and then cool to obtain a cerium oxide tubular film, wherein the temperature rise (or temperature drop) rate is 1°C / min when the temperature is higher than 600°C; or cooling) at a rate of 2°C / min. Through the contact angle test, the result shows that the contact angle of the hydrophobic inorganic porous membrane to the water phase is 106°.

[0031] In this example: in the support body mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com