Method and equipment for treating organic polluted soil by two-stage indirect thermal desorption process

A technology for organic pollution and organic pollutants, applied in the field of organic pollution treatment by two-stage indirect thermal analysis process, can solve the problems of complete decomposition and harmless treatment of organic pollutants, ineffective treatment of organic pollutants, exhaust gas purification System complexity and other problems, to achieve the effect of saving exhaust gas purification facilities, significant energy saving and environmental protection benefits, and significant energy saving and emission reduction benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the processing of organic polluted soil

[0035] The present invention will be further described below in conjunction with accompanying drawing:

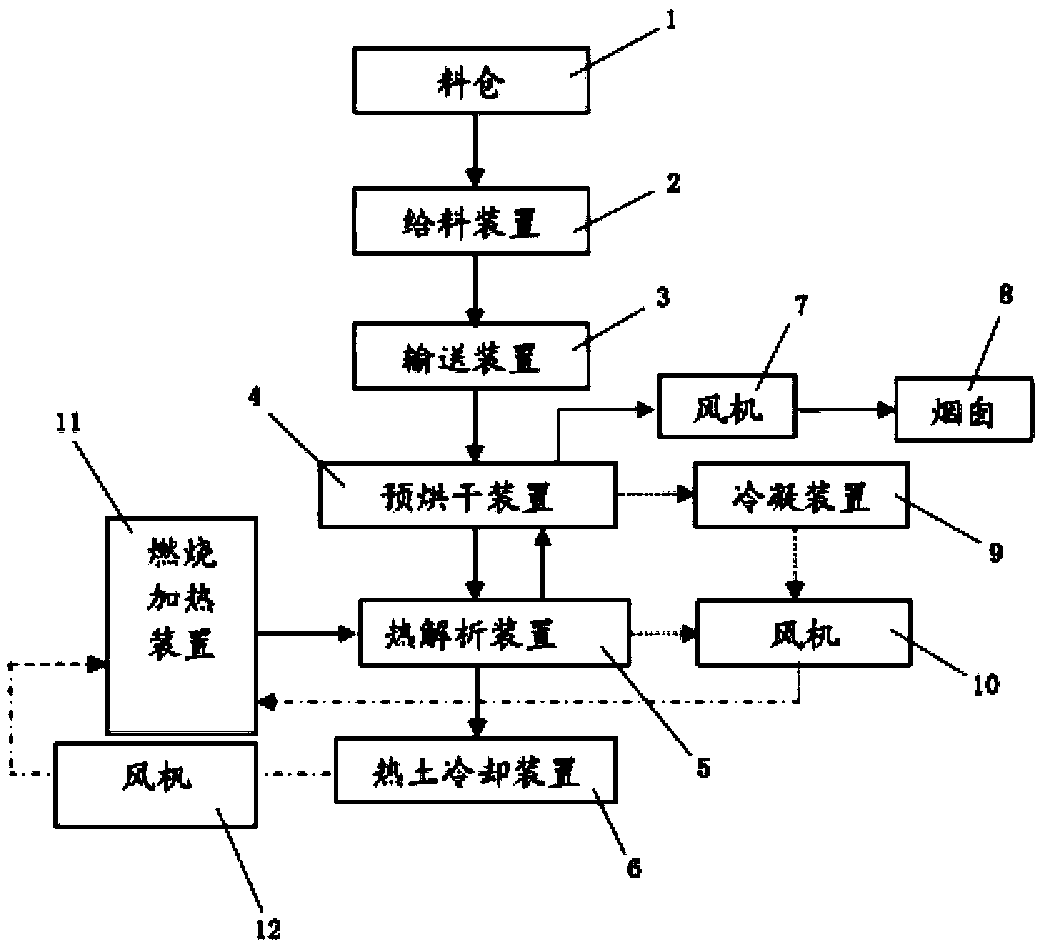

[0036] see figure 1 . Among them, 1. Material bin, 2. Feeding device, 3. Conveying device, 4. Pre-drying device, 5. Thermal analysis device, 6. Hot soil cooling device, 7.1# fan, 8. Chimney, 9. Condensing device, 10.2 # Fan, 11. Combustion device, 12.3# induced draft fan.

[0037]The equipment for the two-stage indirect thermal desorption process to treat organic contaminated soil includes silo (1), feeding device (2), conveying device (3), pre-drying device (4), thermal desorption device (5), hot soil cooling device (6), combustion heating device (11), 1# fan (7), 2# fan (10) and 3# induced draft fan (12), chimney (8) and condensation device (9); ) outlet is connected with the feed port of the feeding device (2); the discharge port of the feeding device (2) is connected with the feed port of the conveying d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com