Nanometer reflective heat-insulation coating for exterior wall and preparation technique thereof

A technology for reflective thermal insulation coatings and building exterior walls, applied in reflective/signal coatings, multi-color effect coatings, coatings, etc., can solve problems such as reflection efficiency discount, achieve excellent thermal insulation effect, solve poor dispersion, improve The effect of solar reflectance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

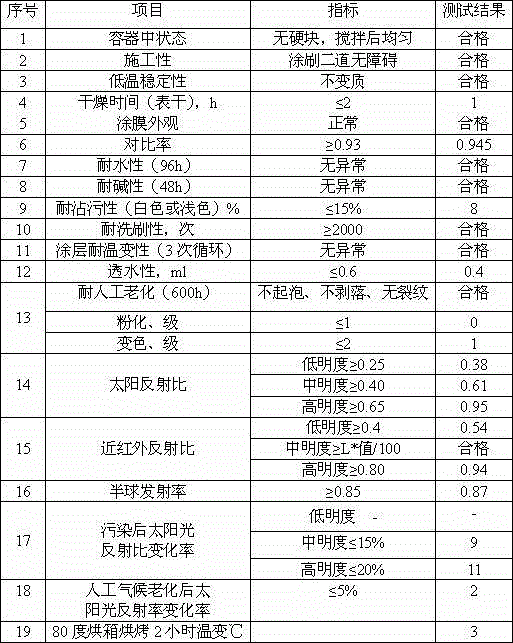

Image

Examples

Embodiment 1~4

[0037] Embodiment 1~4: a kind of nano-reflective heat-insulating coating for building exterior wall, is made up of the component of following parts by weight:

[0038] 8.5 to 24 parts of water,

[0039] Hydroxyethyl cellulose ether 0.05~0.5 part,

[0040] 0.03~0.3 parts of 2-amino-2-methyl-1-propanol,

[0041] 0.3-0.8 parts of polyacrylic acid ammonium salt dispersant,

[0042] Alcohol surfactant 0.01~0.03 parts,

[0043] Defoamer 0.1~0.6 parts,

[0044] CMIT / MIT compound 0.1~0.4 parts,

[0045] 1.05 to 2 parts of film-forming aids,

[0046] 1 to 2 parts of antifreeze,

[0047] 10-25 parts of modified rutile titanium dioxide,

[0048] Filling 2 to 5 parts,

[0049] 20-45 parts of nano-metal hybrid paste,

[0050] 7 to 20 parts of colored hollow ceramic microbeads,

[0051] Emulsion 22~45 parts,

[0052] Leveling agent 0.05~0.5 parts,

[0053] Alkali-swellable thickener 0.1-0.8 parts;

[0054] The filler is at least one of calcined kaolin, sericite, and heavy calci...

Embodiment 1

[0059] The nano-silicon oxide monomer solution, the nano-alumina monomer solution, the nano-zinc oxide monomer solution and the nano-titanium nitride monomer solution in the nano-metal hybrid slurry in Example 1 were mixed according to the volume ratio of 4.5:4.5:3.8:1 ; Nano silicon oxide monomer solution, nano aluminum oxide monomer solution, nano zinc oxide monomer solution and nano titanium nitride monomer solution in the nano metal hybrid slurry in embodiment 2 according to the volume ratio of 5: 4.8: 4.2: 1.2 Mixing; Nano silicon oxide monomer solution, nano aluminum oxide monomer solution, nano zinc oxide monomer solution and nano titanium nitride monomer solution in the nano metal hybrid slurry in embodiment 3 according to the volume of 4.8:5.2:3.8:1.5 Ratio mixing; nano-silicon oxide monomer solution, nano-alumina monomer solution, nano-zinc oxide monomer solution and nano-titanium nitride monomer solution in the nano-metal hybrid slurry in embodiment 4 according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com