Method for producing protein feed material by enzymolysis and fermentation of guar meal

A technology of guar soybean meal and protein feed, which is applied in the field of guar soybean meal enzymolysis and fermentation to produce protein feed raw materials, can solve the problems of reducing the digestibility of nutrients, increasing the viscosity of chyme in the digestive tract, etc., to reduce the pollution of miscellaneous bacteria, The effect of shortening the fermentation cycle and high biotransformation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

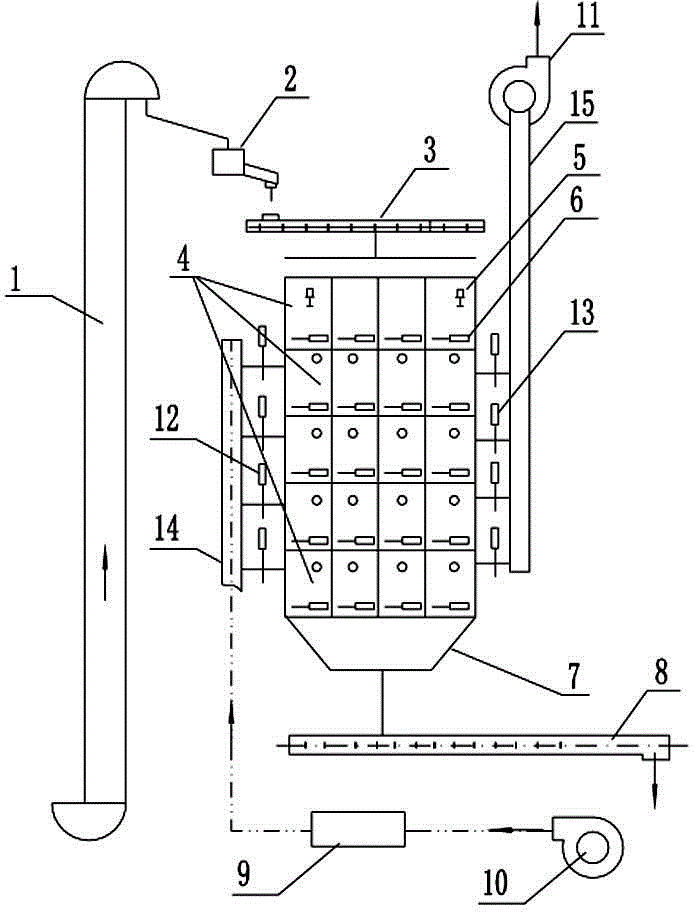

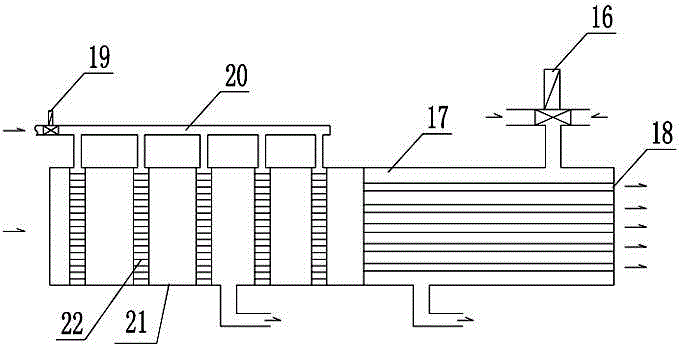

Image

Examples

Embodiment 1

[0051] The method for producing protein feed material by enzymatic hydrolysis and fermentation of guar soybean meal of the present invention comprises the following steps:

[0052] The first step, liquid fermentation

[0053] The specific preparation method of Candida utilis fermented liquid, Bacillus natto fermented liquid, Lactobacillus plantarum fermented liquid is the same as described in the specific embodiment, and it is standby to make mixed bacterial liquid by the ratio of 1:1:1;

[0054] The second step, solid enzymatic hydrolysis and fermentation

[0055] a. Put the raw material of guar soybean meal into the explosion tank, the filling coefficient is 60~80%, and the saturated steam at 215°C is introduced after the explosion tank body is sealed. steam explosion;

[0056] b. Mix the gas-exploded material, the mixed bacterial solution prepared in the first step, and molasses in a mixer at a weight ratio of 1:1.2:0.08, and add neutral protease 75 U / g raw materials, ...

Embodiment 2

[0063] The method for producing protein feed material by enzymatic hydrolysis and fermentation of guar soybean meal of the present invention comprises the following steps:

[0064] The first step, liquid fermentation

[0065] The specific preparation method of Candida utilis fermented liquid, Bacillus natto fermented liquid, Lactobacillus plantarum fermented liquid is the same as described in the specific embodiment, and it is standby to make mixed bacterial liquid by the ratio of 2:1:1;

[0066] The second step, solid enzymatic hydrolysis and fermentation

[0067] a. Put the raw material of guar soybean meal into the explosion cylinder, the filling coefficient is 60~80%. After the explosion cylinder is sealed, the saturated steam at 185°C is introduced. When the pressure of the explosion cylinder reaches 0.5Mpa, keep it for 10 minutes, and immediately open the pneumatic valve to carry out steam explosion;

[0068] b. Mix the gas-exploded material, the mixed bacterial liq...

Embodiment 3

[0075] The method for producing protein feed material by enzymatic hydrolysis and fermentation of guar soybean meal of the present invention comprises the following steps:

[0076] The first step, liquid fermentation

[0077] The specific preparation method of Candida utilis fermented liquid, Bacillus natto fermented liquid, Lactobacillus plantarum fermented liquid is the same as described in the specific embodiment, and it is standby to make mixed bacterial liquid by the ratio of 2:2:1;

[0078] The second step, solid enzymatic hydrolysis and fermentation

[0079] a. Put the raw material of guar soybean meal into the explosion cylinder, the filling coefficient is 60~80%, and the explosion cylinder tank is sealed and then filled with saturated steam at 250°C. When the pressure of the explosion cylinder reaches 2.0Mpa, keep it for 0.5min, and immediately open the pneumatic valve conduct steam explosion;

[0080] b. Mix the material after gas explosion, the mixed bacterial so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com