Nitrogen-doped mesoporous carbon sphere nanomaterial and preparation method thereof

A technology of nitrogen-doped mesoporous carbon and nanomaterials, applied in the direction of nanotechnology, hybrid capacitor electrodes, etc., can solve the problem of high nitrogen doping amount and high specific surface area carbon spheres, which affect the electrochemical performance of electrode materials, and cannot be obtained at the same time. Specific surface area and other issues, to achieve the effect of improving migration, suitable for large-scale production, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A preparation method of nitrogen-doped mesoporous carbon sphere nanomaterials, specifically comprising the following steps:

[0047] (1) Disperse 0.3g of cationic surfactant in 6g of solvent, stir at room temperature for 5min, add 0.06g of alkaline substance and stir evenly, then add 0.06g of organic silicon source, 0.06g of organic carbon source and 0.06g of organic nitrogen Source, control the temperature at 30°C, react under stirring conditions for 48h, filter the obtained reaction solution, and dry the obtained filter cake at 80°C for 12h to obtain the organic / inorganic compound;

[0048] Described solvent is deionized water;

[0049] Described alkaline substance is sodium hydroxide;

[0050] Described cationic surfactant is cetyltrimethylammonium bromide;

[0051] The organic carbon source is a mixture obtained by mixing resorcinol and formaldehyde in a mass ratio of 1:4;

[0052] Described organosilicon source is tetramethyl orthosilicate;

[0053] Described o...

Embodiment 2

[0066] A preparation method of nitrogen-doped mesoporous carbon sphere nanomaterials, specifically comprising the following steps:

[0067] (1) Disperse 0.3g of cationic surfactant in 21g of solvent, stir at room temperature for 5min, add 1.5g of alkaline substance and stir evenly, then add 1.5g of organic silicon source, 1.5g of organic carbon source and 1.5g of organic Stir the nitrogen source evenly, control the temperature at 50°C to react for 48 hours, filter the obtained reaction solution, and dry the obtained filter cake at 80°C for 12 hours to obtain an organic / inorganic compound;

[0068] Described solvent is deionized water;

[0069] Described alkaline substance is potassium hydroxide;

[0070] Described cationic surfactant is tetradecyl dimethyl benzyl ammonium chloride;

[0071] The organic carbon source is calculated by mass ratio of furfuryl alcohol and formaldehyde, that is, furfuryl alcohol: formaldehyde is a mixture composed of 1:4;

[0072] Described organ...

Embodiment 3

[0082] A preparation method of nitrogen-doped mesoporous carbon sphere nanomaterials, specifically comprising the following steps:

[0083] (1) Disperse 0.3g of cationic surfactant in 24g of solvent, stir at room temperature for 5min, add 2.4g of alkaline substance and stir evenly, then add 2.4g of organic silicon source, 2.4g of organic carbon source and 2.4g of organic stirring Evenly, control the temperature at 80°C to react for 48 hours, filter the obtained reaction solution, and dry the obtained filter cake at 80°C for 12 hours to obtain an organic / inorganic compound;

[0084] Described solvent is deionized water;

[0085] Described alkaline substance is the ammoniacal liquor that mass percent concentration is 25%;

[0086] Described cationic surfactant is octadecyl dimethyl benzyl ammonium chloride;

[0087] The organic carbon source is calculated by mass ratio of furfuryl alcohol and formaldehyde, that is, furfuryl alcohol: formaldehyde is a mixture composed of 1:4; ...

PUM

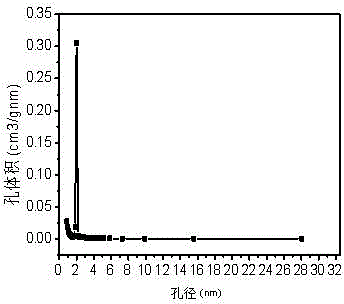

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com