Use of nanoporous molybdenum disulfide controlled by mechanical strain in seawater desalination

A technology of molybdenum disulfide and mechanical strain, which is applied in seawater treatment, general water supply saving, osmosis/dialysis water/sewage treatment, etc., can solve the problems that have not been reported in the application, achieve the expansion of application scale, reduce production cost, and benefit The effect of long-term sustainable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Molecular dynamics simulation experiment of seawater desalination process.

[0026] In this example, the molecular dynamics simulation experiment is used to evaluate the performance of the nanoporous molybdenum disulfide filter membrane in the seawater desalination process under different strain conditions. The specific process is as follows:

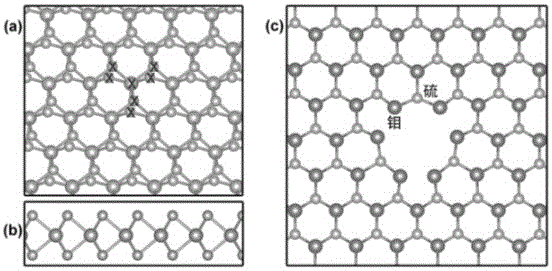

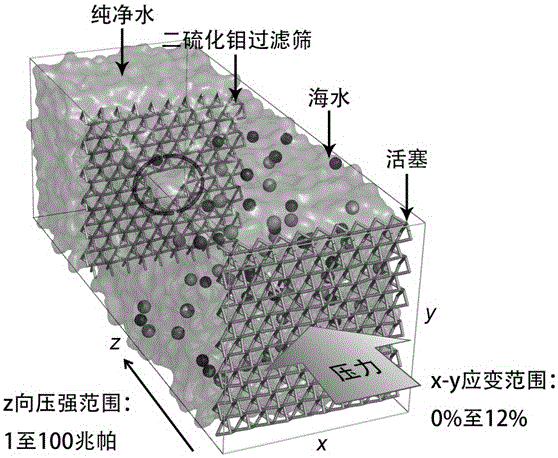

[0027] learn from J.Am.Chem.Soc ., 2008, 130, p16448 and Nano Lett ., 2012, 12, the research method of graphene molecular sieve recorded in p3602, using Comput.Mater.Sci .,2010,48,p101 reported molybdenum disulfide crystal structure model, constructed by computer modeling such as figure 2 The length, width and height of the water tank shown correspond to the z-axis, x-axis and y-axis in the three-dimensional Cartesian coordinate system, respectively. The tank is divided into two areas by a nanoporous molybdenum disulfide filter membrane, one side is simulated seawater containing sodium chloride (NaCl), and the o...

Embodiment 2

[0029] Example 2: Experiment on the quantitative relationship between filter membrane strain and water channel.

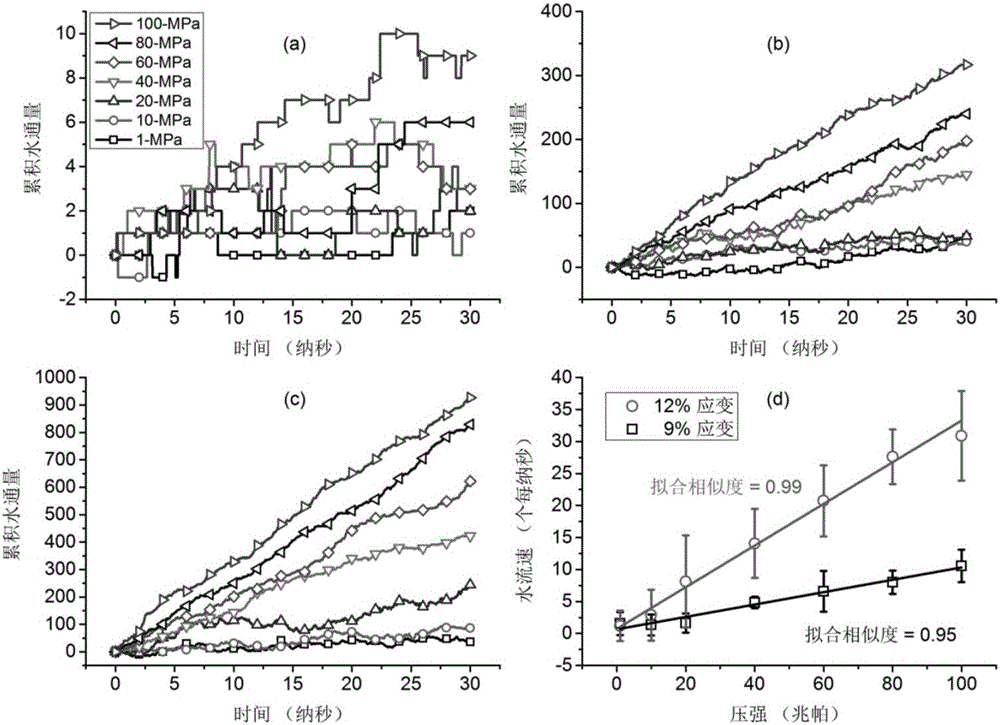

[0030] In order to quantitatively compare the effects of filter membrane strain on water channels, this example calculates the water flux projected on the cross-section of the molybdenum disulfide filter membrane at the strain levels of 9% (a) and 12% (b). The result is as Figure 4 shown.

[0031] Depend on Figure 4 It can be seen that under the 9% strain condition, three flow channels for conducting water (this region is marked as "A" in (a)) appear near the midpoint of the edges used to define the nanopore triangle. When the strain is increased to 12%, three additional flow channels (marked as “B” in (b)) appear at the corners of the nanopore triangle. It appears that the tension-based control of the MoS2 filter membrane itself can be simply attributed to the structural changes in the nanopores under tension-strain conditions: stretching enlarges the nanopor...

Embodiment 3

[0032] Example 3: Quantification of Molybdenum Disulfide Filtration Membrane Selectivity—Research on the density distribution of water and inorganic salt ions on both sides of the nanopore.

[0033] In this example, a simulated water tank without a piston is used, and the same concentration of brine is set on both sides of the filter membrane. We hope to induce the solvent and ion structure near the nanopore by studying the "open" and "closed" states of the molybdenum disulfide filter membrane The process of changing to examine the selectivity of the molybdenum disulfide filter membrane, the results are as follows Figure 5 shown.

[0034] Depend on Figure 5 It can be seen that when the filter membrane is subjected to 9% and 12% strain levels, the density distribution curve of water shows two peaks near the molybdenum disulfide filter membrane (located at |Z|=0.43 and 0.73nm respectively), representing The first and second solvation interfaces of the molybdenum disulfide ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com